Efficient heat exchange tube for LNG vaporizer and open rack vaporizer

An open-frame gasifier and liquefied natural gas technology, applied in indirect heat exchangers, heat exchanger types, tubular elements, etc., can solve the problem of unreasonable structural design, safe operation of equipment, deformation and displacement, and stable operation of equipment that affects heat transfer efficiency. and other problems, to achieve the effect of simple manufacturing and installation, improving efficiency and enhancing heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

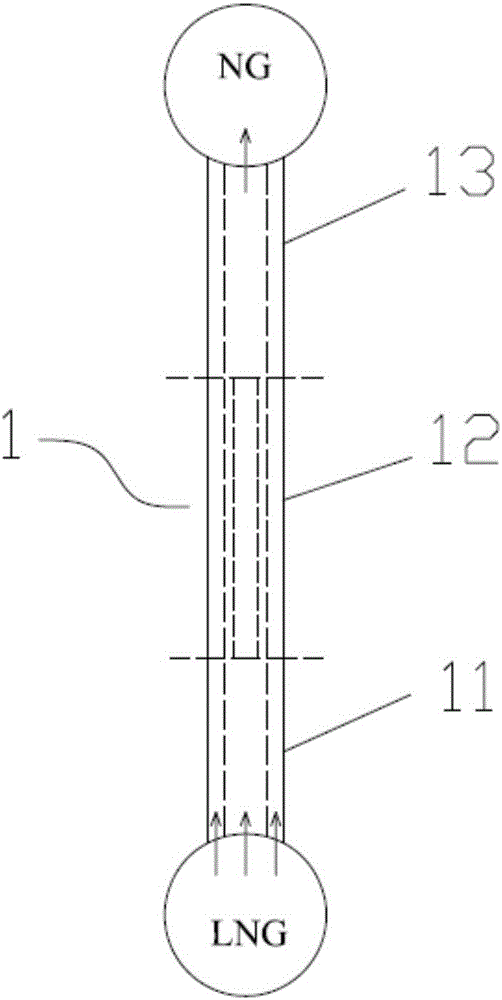

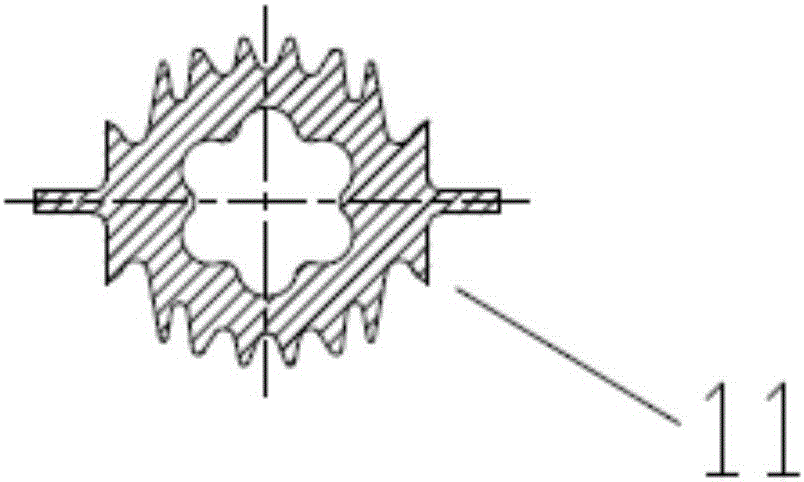

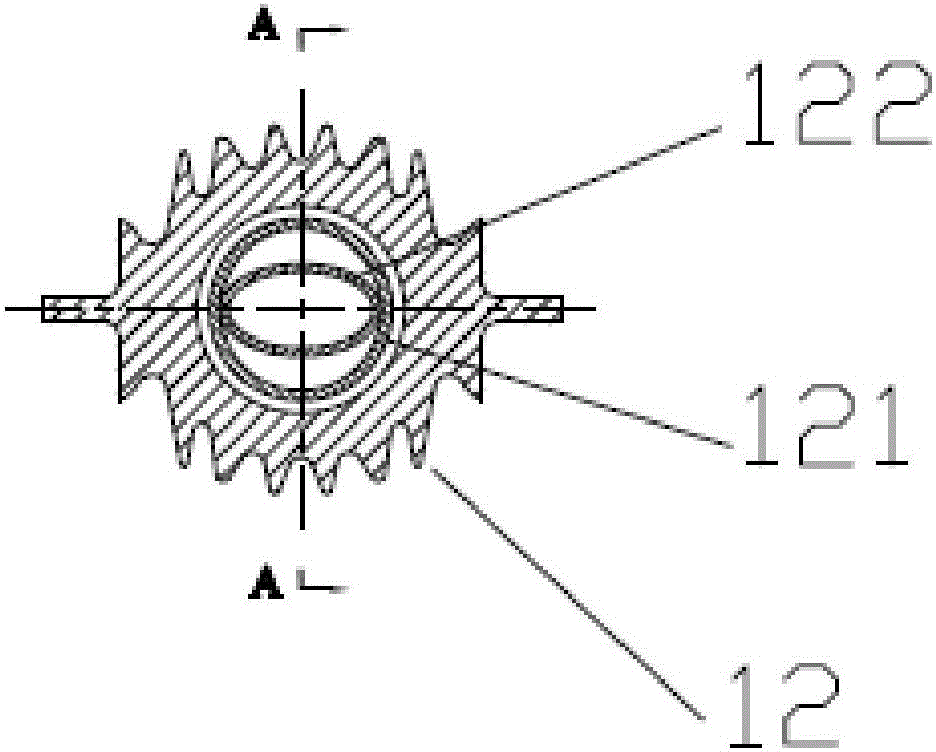

[0033] Such as Figure 1-5 As shown, a high-efficiency heat exchange tube for an open-frame gasifier, the outer wall of the high-efficiency heat exchange tube 1 is a straight fin structure, and the height of the fins on the same section can be the same or different. The high-efficiency heat exchange tube 1 is divided into three parts: a heating section 11, a gasification section 12, and a superheating section 13; tube; in the gasification section 12, the inner wall of the high-efficiency heat exchange tube 1 is a smooth surface or a channel structure, and the inner tube 121 of the gasification section is set inside the tube, and the inner tube 121 of the gasification section is a threaded pipe structure. The inner pipe 121 of the gasification section is also set with the inner pipe 122 of the gasification section. The inner pipe 122 of the gasification section is a twisted tube structure; Channel structure, the inner pipe 131 of the superheating section is sleeved in the pipe...

Embodiment 2

[0035] A high-efficiency heat exchange tube for an open-frame gasifier differs from Embodiment 1 in that the outer wall of the high-efficiency heat exchange tube 1 is a spiral fin structure, and the height of the fins on the same section can be the same or different.

Embodiment 3

[0037] An open-frame gasifier, including several groups of plate-shaped tube bundles and seawater spraying systems, each group of plate-shaped tube bundles is composed of several high-efficiency heat exchange tubes 1 arranged in a plate shape (each heat exchange tube is arranged in parallel), each high-efficiency Both ends of the heat exchange tube 1 communicate with the gas collecting pipe 3 and the liquid collecting pipe 2 respectively. When the open-frame gasifier is working, the seawater spray system sprays seawater on the outer surface of the plate-shaped tube bundle. Relying on the action of gravity, the seawater flows from top to bottom along the outer wall of the high-efficiency heat exchange tube 1. Liquid natural gas (LNG) Flow from the liquid collecting pipe 2 into each high-efficiency heat exchange tube 1 one by one, and flow from bottom to top in the tube. Seawater transfers heat to liquid natural gas (LNG). After passing through the heating section 11, gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com