Pipe jacking machine tool pipe and its application

A technology of tool pipe and pipe jacking machine, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipeline laying and maintenance, etc. It can solve the problems of long construction period, increase the direct cost of the project, prolong the construction period, etc., and achieve good economic benefits and social benefits, easy to make and reuse, and simple construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

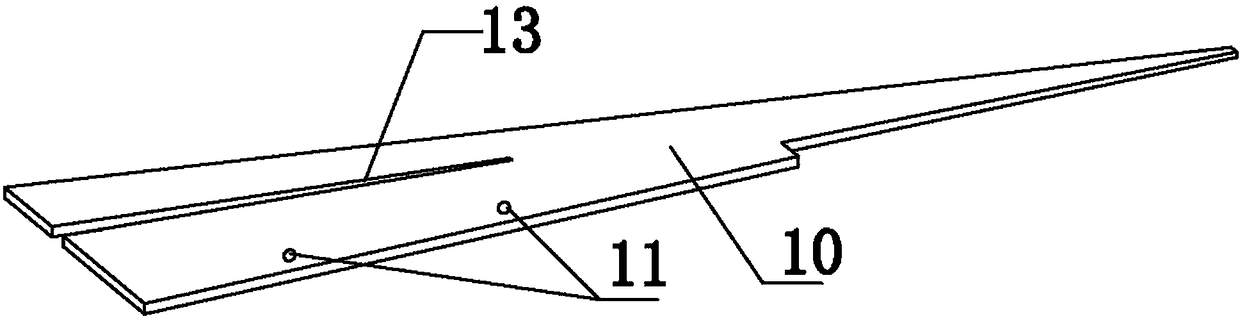

[0023] Depend on Figure 1 to Figure 6 It can be seen that a pipe jacking machine tool pipe comprises a pipe body 1, and the inner side of the front end of the pipe body 1 is provided with a compacting mechanism and a pushing mechanism of the compacting mechanism; 5. The compacting block 9 composed of the end plate 6, the first connecting side plate 10 and the second connecting side plate 8, and the mortise and tenon on the first connecting side plate 10 and the second connecting side plate 8 are formed between the compacting blocks 9 The mechanism is connected into a squeeze ring, and the squeeze ring can move axially in the tool tube; the propulsion mechanism includes a jack 19 and a bracket, the bracket is installed on the inside of the pipe body 1, the cylinder of the jack 19 is installed on the bracket, and the piston of the jack 19 It is in contact with the end plate 6 on the compacting block 9 .

[0024] The mortise and tenon mechanism of the present invention includes...

Embodiment 2

[0033] In order to install the earth retaining plate, the conical plate 5 of the present invention is provided with a limit plate 12, and a limit groove 15 is formed between the end plate 6 and the limit plate 12, and an earth retaining plate is installed in the limit groove 15; the earth retaining plate It includes a top earth retaining board 20 , a perforated earth retaining board 21 , a non-porous earth retaining board 22 and a bottom earth retaining board 23 .

[0034] For the convenience of installing the earth retaining plate, the earth retaining plate of the present invention is provided with a handle. Handles are all provided on the top floor earth retaining plate 20 , the perforated earth retaining plate 21 , the non-porous earth retaining plate 22 and the bottom earth retaining plate 23 .

[0035] In order to realize the grouting operation, the perforated soil retaining plate 21 of the present invention is provided with a grouting hole 24 .

[0036] An application o...

Embodiment 3

[0041] An application of the tool pipe of a pipe jacking machine as described above in pipe jacking construction, that is, when there is an obstacle in front of the pipe face or the soil with good self-stabilization performance, the jack 19 of the propulsion mechanism is depressurized, which can realize the Handling of obstructions or excavation of face openings.

[0042] When the present invention works, when an obstacle appears in front of the drill face or encounters a soil body with strong self-stabilization ability, the jack 19 releases the pressure, and the squeeze ring automatically retracts into the tube body 1 during the tool tube advancement process, which can Realize the treatment of obstacles or the opening excavation of the face.

[0043] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com