Preparation method for micro-nano-cellulose

A technology of micro-nano cellulose and cellulose, applied in fermentation and other directions, can solve the problems of poor uniformity of micro-nano cellulose, achieve uniform size and reduce the effect of acid-base neutralization treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation method of micro-nano cellulose:

[0034] (1) The citric acid-sodium citrate buffer solution of cotton pulp and pH=8.0 is mixed by solid-liquid ratio 1:25g / mL, adds the cellulase (Novozymes company model is 20IU / g with cotton pulp ratio) The cellulase of D) was shaken at 50°C for 12h to obtain a cellulose suspension, filtered and washed, and the filtrate was inactivated at a high temperature of 80°C;

[0035] (2) finely refining the cellulose treated in step (1) under a pressure of 1000 Bar to obtain a micron cellulose slurry with a slurry concentration of 18 wt %;

[0036] (3) The micron cellulose slurry was subjected to a high-strength micro-jet homogenization treatment at 8° C. with a high-pressure micro-jet homogenizer at a pressure of 100 MPa, and finally freeze-dried at -10° C. to obtain micro-nano cellulose.

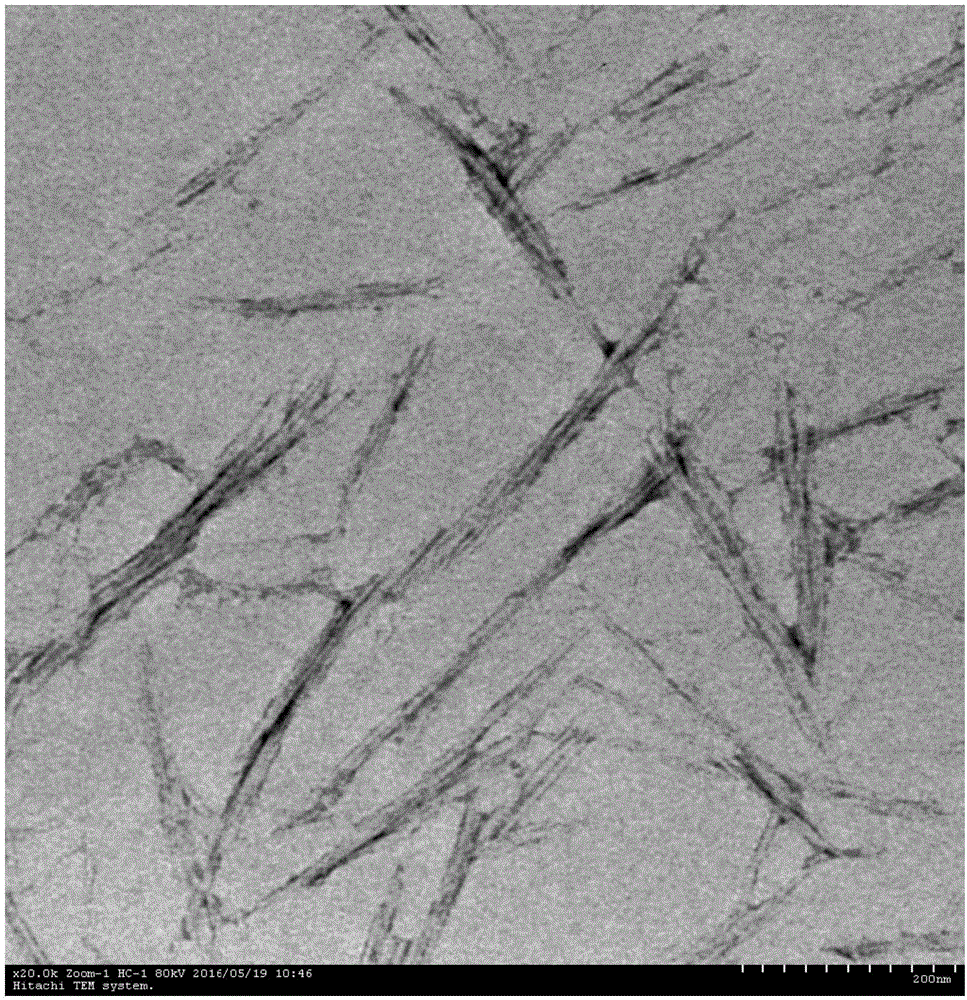

[0037] The prepared micronanocellulose such as figure 1 shown by figure 1 It can be seen that the prepared micro-nano fibers have good dispe...

Embodiment 2

[0039] Preparation method of micro-nano cellulose:

[0040] (1) Wood pulp is mixed with the citric acid-sodium citrate buffer solution of pH=6.0 by solid-liquid ratio 1:28g / mL, add the cellulase (the model of Novozymes company is 32IU / g with wood pulp ratio) U cellulase), shaken at 40°C for 18h to obtain a cellulose suspension, filtered and washed, and the filtrate was inactivated at 85°C at high temperature;

[0041] (2) finely refining the cellulose treated in step (1) under a pressure of 1200 Bar to obtain a micron cellulose slurry with a slurry concentration of 20 wt %;

[0042] (3) The micron cellulose slurry was subjected to a high-strength micro-jet homogenization treatment at 4°C with a high-pressure micro-jet homogenizer at a pressure of 90 MPa, and finally freeze-dried at -20°C to obtain micro-nano cellulose.

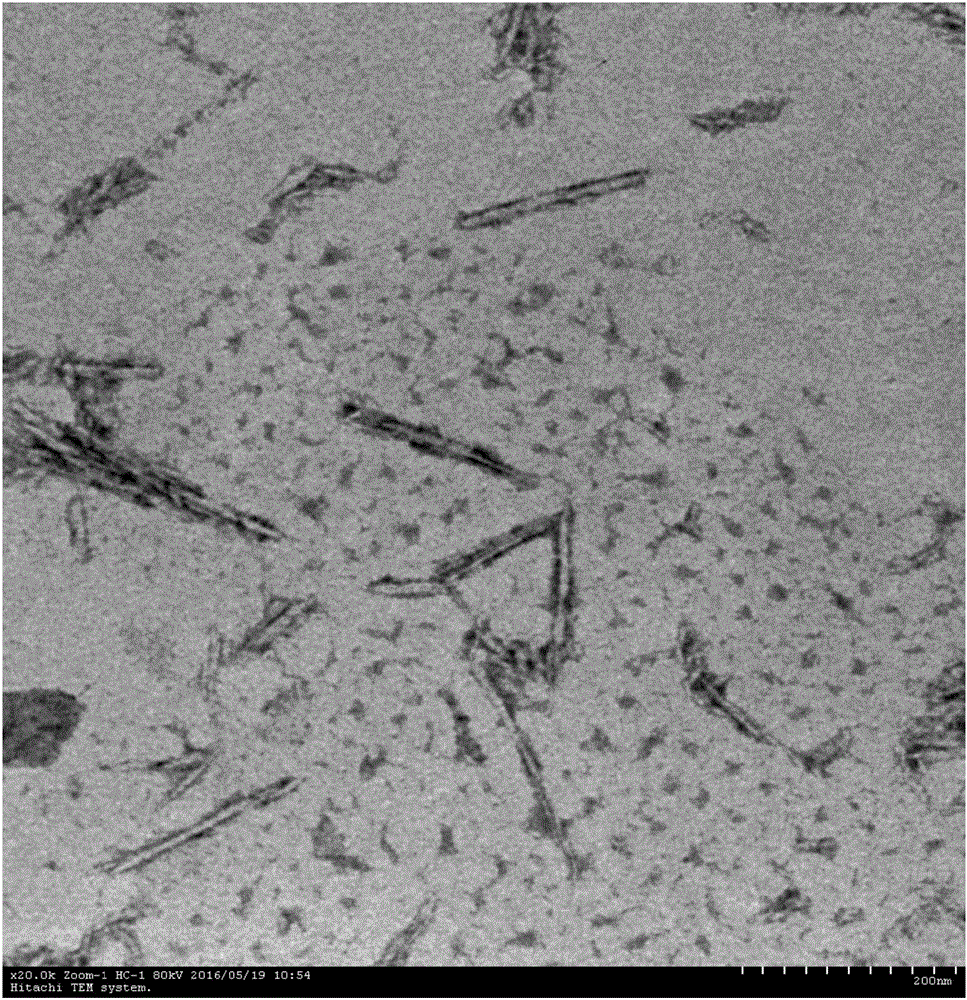

[0043] The prepared micronanocellulose such as figure 2 shown by figure 2 It can be seen that the prepared micro-nano fibers have good dispersion and un...

Embodiment 3

[0045] Preparation method of micro-nano cellulose:

[0046] (1) Cotton pulp is mixed with the phosphate buffer saline solution of pH=5.0 by solid-liquid ratio 1:35g / mL, adds the cellulase (the acidic fiber of Suhong Cellish L that the Novozymes company model is Suhong Cellish L with the ratio of cotton pulp) Suspension) was shaken at 45°C for 24 hours to obtain a cellulose suspension, filtered and washed, and the filtrate was inactivated at a high temperature of 85°C;

[0047] (2) finely refining the cellulose treated in step (1) under a pressure of 1300 Bar to obtain a micron cellulose slurry with a slurry concentration of 10 wt %;

[0048] (3) The micron cellulose slurry was subjected to a high-strength micro-jet homogenization treatment at 6° C. with a high-pressure micro-jet homogenizer at a pressure of 80 MPa, and finally freeze-dried at -25° C. to obtain micro-nano cellulose.

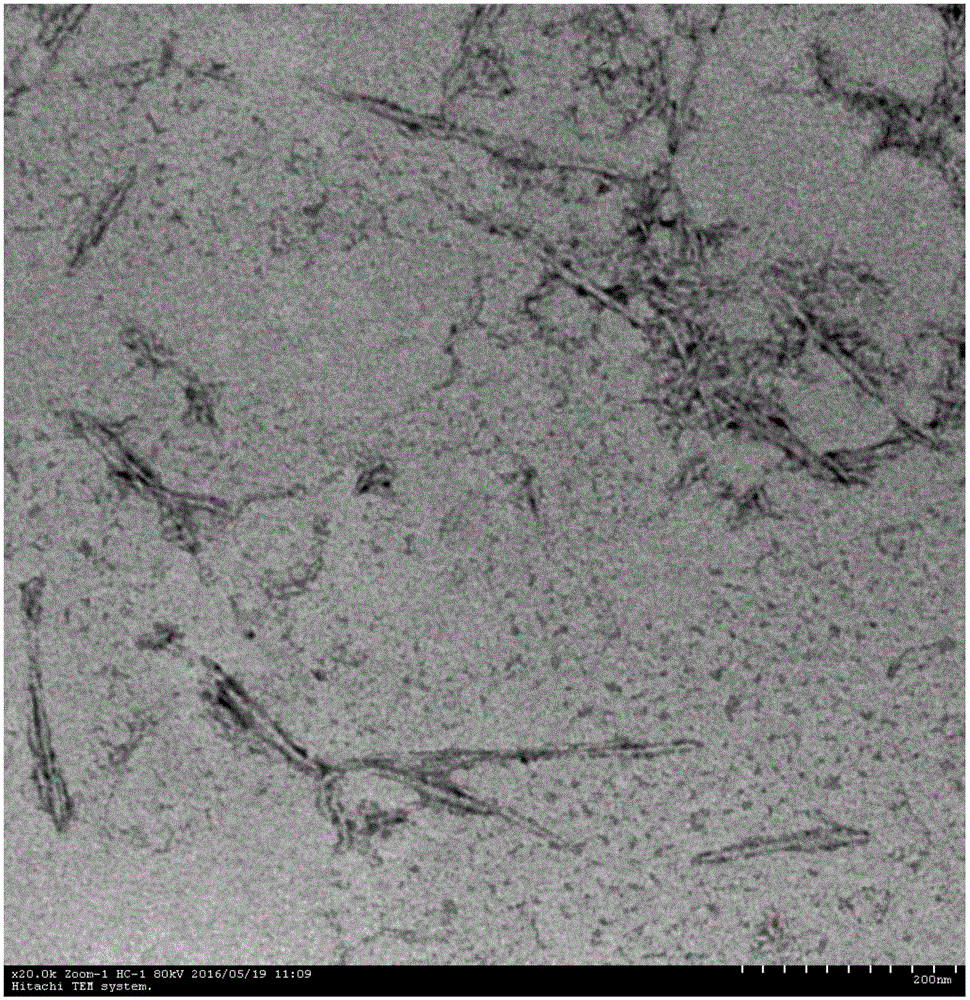

[0049] The prepared micronanocellulose such as image 3 shown by image 3 It can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com