Residual oil hydrotreating method

A treatment method and residue hydrogenation technology are applied in the fields of heavy residue oil hydrotreating and residue oil hydrotreating. The effect of improving reaction performance and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

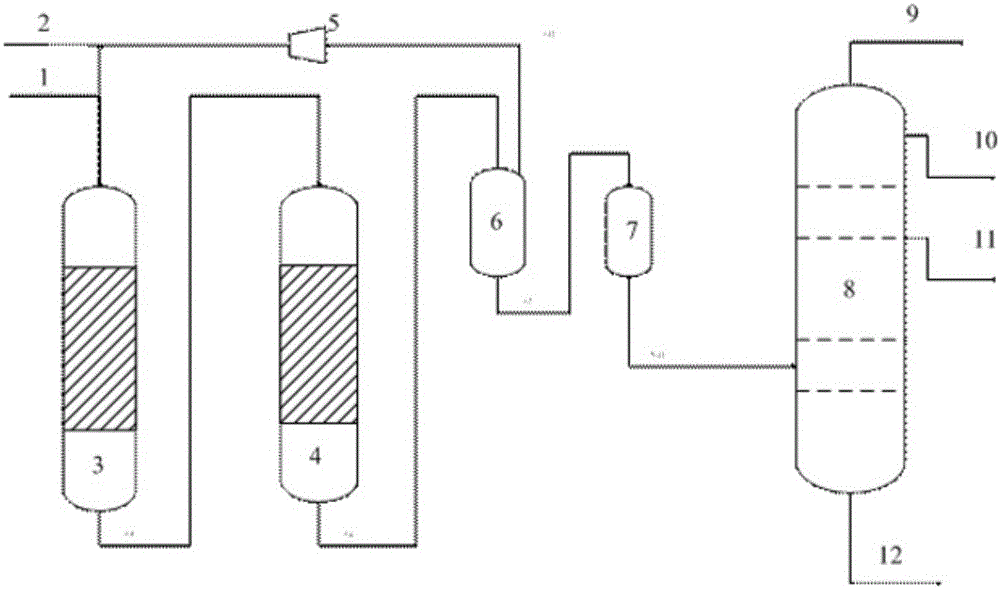

[0020] Such as figure 1 Shown: On the basis of the raw residue oil fixed-bed hydrogenation unit feed, blending 3% catalytic diesel oil to obtain the feed 1, mixed with fresh hydrogen 2, enters the fixed-bed hydrogenation reactors 3 and 4, and then Through hydrogenation protection agent, hydrodemetallization catalyst, hydrodesulfurization catalyst, hydrodenitrogenation catalyst and hydrodecarbonization catalyst; the reaction temperature is 400°C, the hydrogen pressure is 15MPa, and the reaction space velocity is 1.2. After the obtained product enters the thermal high fraction 6, the remaining hydrogen is re-mixed with the fresh hydrogen 2 through the circulating hydrogen compressor 5 and then enters the reaction system. Hydrogen tail oil 12, hydrogenated tail oil can be used as feed for catalytic cracking unit.

Embodiment 2

[0022] Such as figure 1 Shown: On the basis of raw residue oil fixed-bed hydrogenation unit feed, blending 2% mass fraction of catalytic diesel oil and 2% mass fraction of pyrolysis diesel oil to obtain feed 1, mixed with fresh hydrogen 2 and then entering the fixed-bed hydrogenation unit Hydrogen reactors 3 and 4 pass through hydrogenation protecting agent, hydrodemetallization catalyst, hydrodesulfurization catalyst, hydrodenitrogenation catalyst and hydrodecarbonization catalyst in sequence; the reaction temperature is 380°C, the hydrogen pressure is 16MPa, and the reaction space velocity is 0.8. After the obtained product enters the thermal high fraction 6, the remaining hydrogen is re-mixed with the fresh hydrogen 2 through the circulating hydrogen compressor 5 and then enters the reaction system. Hydrogen tail oil 12, hydrogenated tail oil can be used as feed for catalytic cracking unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com