Washing method for obtaining low-sulfur hydrated chromic oxide

A hydrated chromium oxide and washing method technology, which is applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of not meeting the requirements of chemical enterprises and the quality requirements of low-sulfur hydrated chromium oxide, so as to save consumption and reduce Safety and environmental protection risks, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

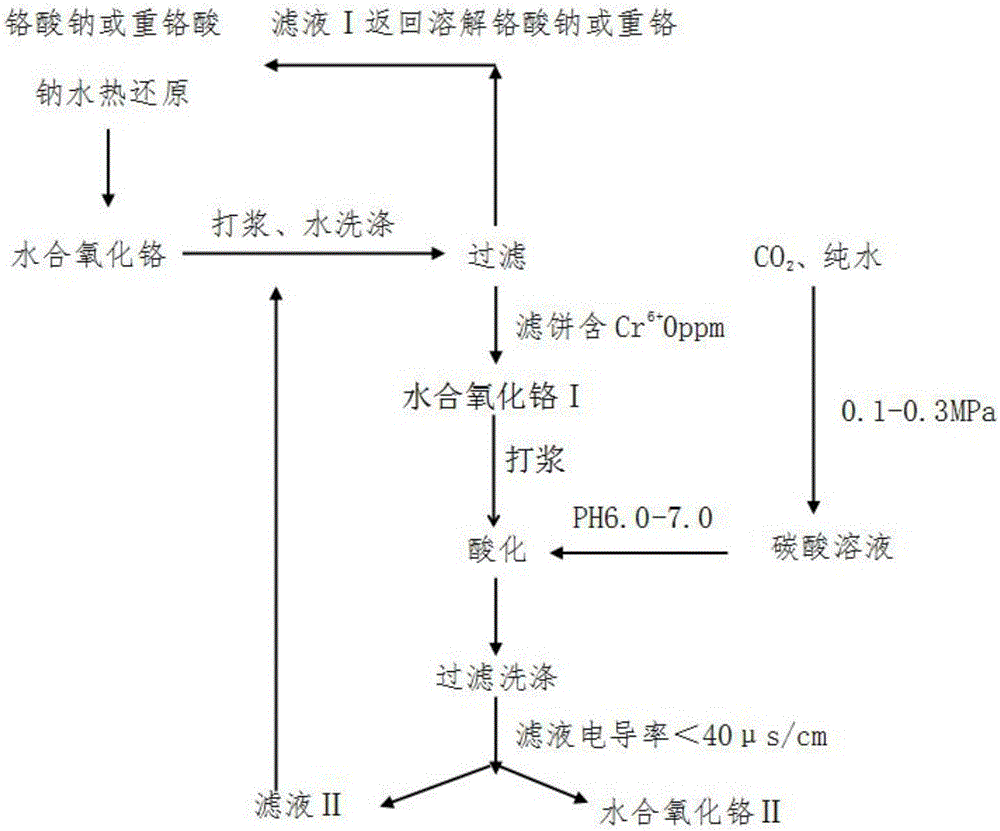

[0026] A washing method for obtaining low-sulfur hydrated chromium oxide, characterized in that it comprises the following steps:

[0027] Step 1, 2000kg and 2.0m of hydrated chromium oxide prepared by hydrothermal reduction of sodium chromate or sodium dichromate 3 Add water into the beating storage tank, raise the temperature to 82°C, beat at a constant temperature for 30 minutes, separate the beating liquid through a vacuum belt filter, and use pure water as the online washing water of the filter, and wash it through the filter on-line countercurrent for 3 stages until the washing liquid Medium Cr 6+ The content is up to 0ppm, and the filtrate I is 5.2m 3 and hydrated chromium oxide I;

[0028] Step 2: Add water to the obtained hydrated chromium oxide I for beating, then add a carbonic acid solution with a pH of 3.6 at room temperature, stir for 15 minutes, acidify the beating solution to a pH of 6.7, heat up to 81°C with steam as a heat source, and keep warm for 35 minut...

Embodiment 2

[0031] A washing method for obtaining low-sulfur hydrated chromium oxide, characterized in that it comprises the following steps:

[0032] Step 1, 2000kg of hydrated chromium oxide prepared by hydrothermal reduction of sodium chromate or sodium dichromate and 2.5m 3 Add water into the beating storage tank, raise the temperature to 85°C, beat at a constant temperature for 40 minutes, separate the beating liquid through a vacuum belt filter, and use pure water as the online washing water of the filter, and wash it through the filter on-line countercurrent for 3 stages until the washing liquid Medium Cr 6+ The content is up to 0ppm, and the filtrate I is 5.6m 3 and hydrated chromium oxide I;

[0033] Step 2: Add water to the obtained hydrated chromium oxide I for beating, then add a carbonic acid solution with a pH of 3 at room temperature, stir for 15 minutes, acidify the beating solution to a pH of 6.2, heat up to 83°C with steam as a heat source, and keep warm for 45 minutes...

Embodiment 3

[0036] A washing method for obtaining low-sulfur hydrated chromium oxide, characterized in that it comprises the following steps:

[0037] Step 1, 1500kg of hydrated chromium oxide prepared by hydrothermal reduction of sodium chromate or sodium dichromate and 1.5m 3 Add water into the beating storage tank, raise the temperature to 80°C, beat at a constant temperature for 30 minutes, separate the beating liquid through a vacuum belt filter, and use pure water as the online washing water of the filter, and wash it through the filter on-line countercurrent for 3 stages until the washing liquid Medium Cr 6+ content up to 0ppm, to obtain filtrate I and hydrated chromium oxide I;

[0038] Step 2. Add water to the obtained chromium oxide hydrate I for beating, then add a carbonic acid solution with a pH of 3 at room temperature, stir for 15 minutes, acidify the beating solution to a pH of 7, heat up to 80°C with steam as a heat source, and keep warm for 60 minutes , to obtain the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com