Device and method for preparing magnesium hydroxide through ultrasonic-assisted magnesium oxide efficient hydration

A magnesium hydroxide and ultrasonic technology, applied in magnesium hydroxide, chemical instruments and methods, chemical/physical/physical-chemical processes of applying energy, etc., can solve the problem of large consumption of magnesium hydroxide, low product purity, and unsatisfactory purity requirements. Advanced problems, to achieve the effect of continuous and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

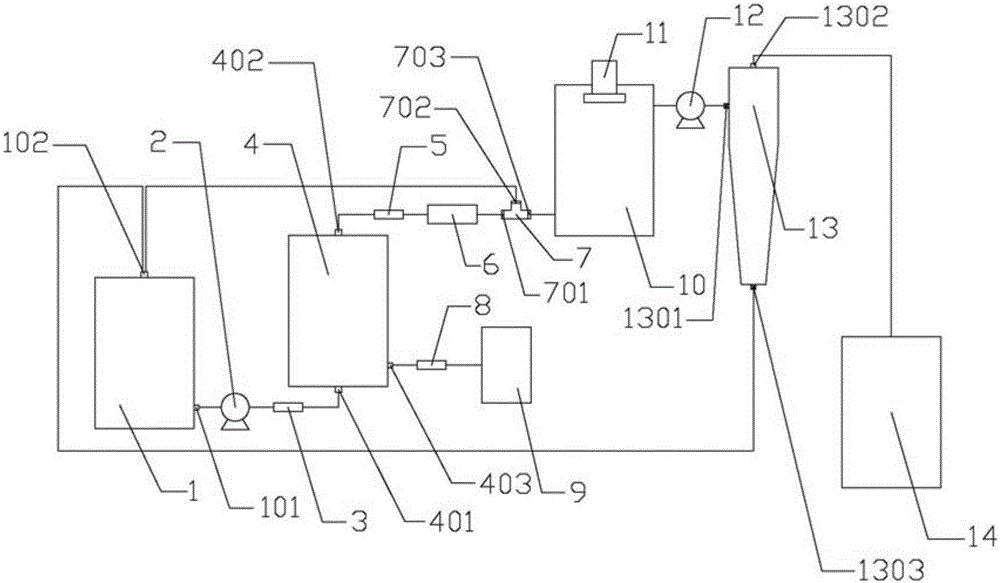

[0031] A device for preparing magnesium hydroxide through the efficient hydration of magnesium oxide assisted by ultrasonic waves. The device includes a mixing tank 1, a pump I2, a pressure control unit I3, a reactor 4, a pressure control unit II5, a condenser 6, and a two-position tee Valve 7, pressure control unit III 8, steam generator 9, circulation cup 10, ultrasonic generator 11, booster pump II 12, hydrocyclone 13, storage tank 14;

[0032] The discharge port 101 of the mixing tank is connected with the feed port 401 of the reactor through the pump I2 and the pressure control unit I3, and the discharge port 402 of the reactor is connected with the pressure control unit II5, the condenser 6 and the two-position three The port I701 of the two-position three-way valve is connected, the port II702 of the two-position three-way valve is connected with the return port 102 of the mixing tank, and the port III703 of the two-position three-way valve is connected to the hydraulic ...

Embodiment 2

[0034] A kind of method that utilizes the supersonic wave of the device described in embodiment 1 to assist magnesium oxide efficient hydration to prepare magnesium hydroxide, described method comprises the steps:

[0035] ① Add magnesium oxide and water to the mixing tank 1, mix well to obtain magnesium oxide slurry;

[0036] Described magnesium oxide accounts for 15% of total weight;

[0037] ②Pump the product obtained in step ① into the reactor 4 through the pump I2, turn on the steam generator 9, feed water vapor into the reactor 4, heat the reactor 4, and control the pressure of the pressure control unit I3 to 0.25MPa, pressure control The pressure of unit Ⅱ5 is 0.25MPa, the pressure of pressure control unit Ⅲ8 is 0.25MPa, and the reaction temperature is 105°C. Open the port II702 of the two-position three-way valve, close the port III703 of the two-position three-way valve, and return the liquid in the reaction to to the mixing tank 1, and then returned to the reactor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com