Inflation-free hollow wheel and assembly method thereof

A non-inflatable, hollow technology, used in wheel assembly equipment, wheels, wheel manufacturing, etc., can solve problems such as the lack of practical application performance, the inability of tires and rims to be tightly combined, etc. , the effect of enhancing bearing capacity and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the present invention is described in further detail:

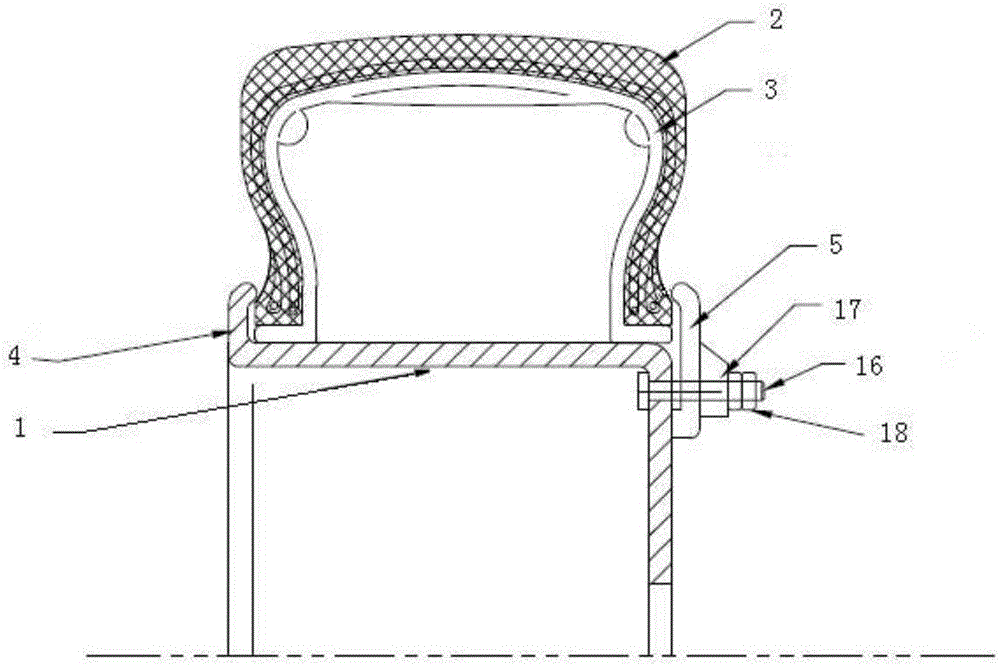

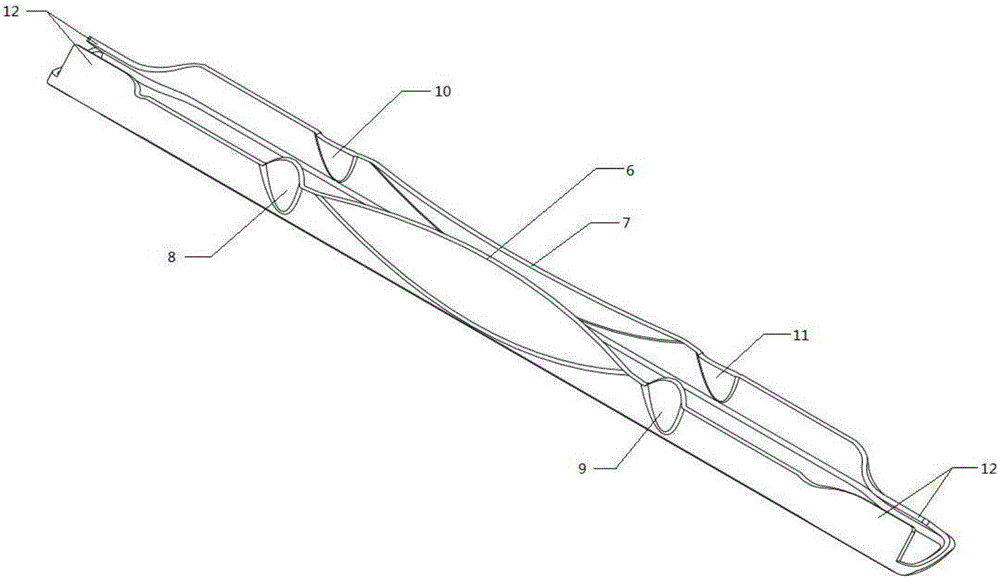

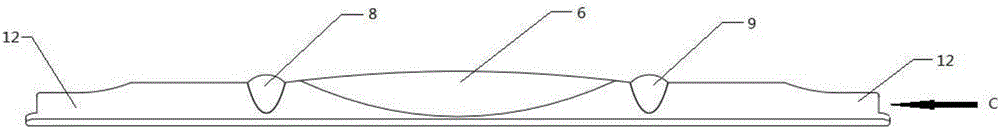

[0025] Such as figure 1 As shown, a kind of air-free hollow wheel of the present embodiment includes a rim 1 and a tire 2 sleeved on the outside of the rim 1, and a plurality of rods are arranged in the annular space formed between the inner side of the tire 2 and the outer side of the rim 1. For the frame 3 supporting the tire 2, the material of the frame 3 is spring steel; the frame 3 is pressed tightly on the inner side of the tire 2 under pressure, and the two ends of the frame 3 are respectively limited to the rim flange 4 and the rim retainer ring 5 inside. Such as Figure 2-4 As shown, the skeleton 3 is provided with two folded edges along the length direction, and one folded edge is provided with a primary deformation cone surface 6 located in the middle of the folded edge and two secondary deformation cone surfaces 8, 9 located on both sides of the primary de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com