Electric spindle device for face grinding

An end face grinding and electric spindle technology, which is applied in the directions of grinding machine parts, grinding/polishing equipment, metal processing equipment, etc. Improve the effect of dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

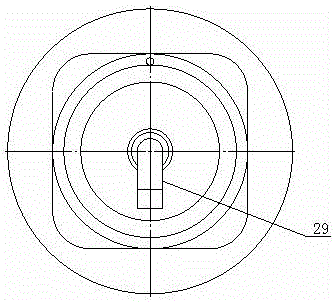

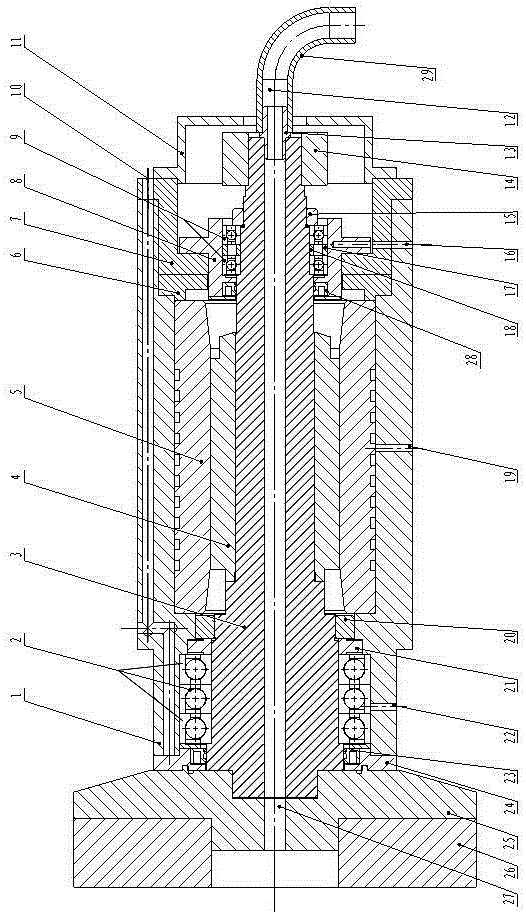

[0019] The end face grinding electric spindle device provided by the present invention includes a casing 1, and the shaft core 3 connected to the end face grinding wheel 26 through the grinding wheel flange 25 is supported by the front and rear shaft core support structures in the casing 1. The shaft core 3 and the housing 1 is provided with a torque motor for driving the shaft core 3 to rotate, and the housing 1 is provided with a circulating water cooling channel 10 and a temperature sensor for detecting the temperature of the shaft core 3 and the torque motor, and the shaft core 3 A grinding fluid channel 27 is provided on the top, and an encoder 14 is provided at the rear end of the shaft core 3 for measurement and feedback of the rotational speed and angle of the shaft core 3; The rotor 4 and the stator 5 fixed on the shell 1, the end of the shaft core 3 is provided with a rotary joint 12 through a straight-through joint 13 to communicate with the grinding fluid channel 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com