Capsule polishing and conveying device

A conveying device and capsule technology, which is applied to grinding/polishing safety devices, surface-polished machine tools, grinding/polishing equipment, etc., can solve the problems of difficulty in removing fine dust, affecting the hygiene quality of capsules, etc. Reasonable structure and uniform polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

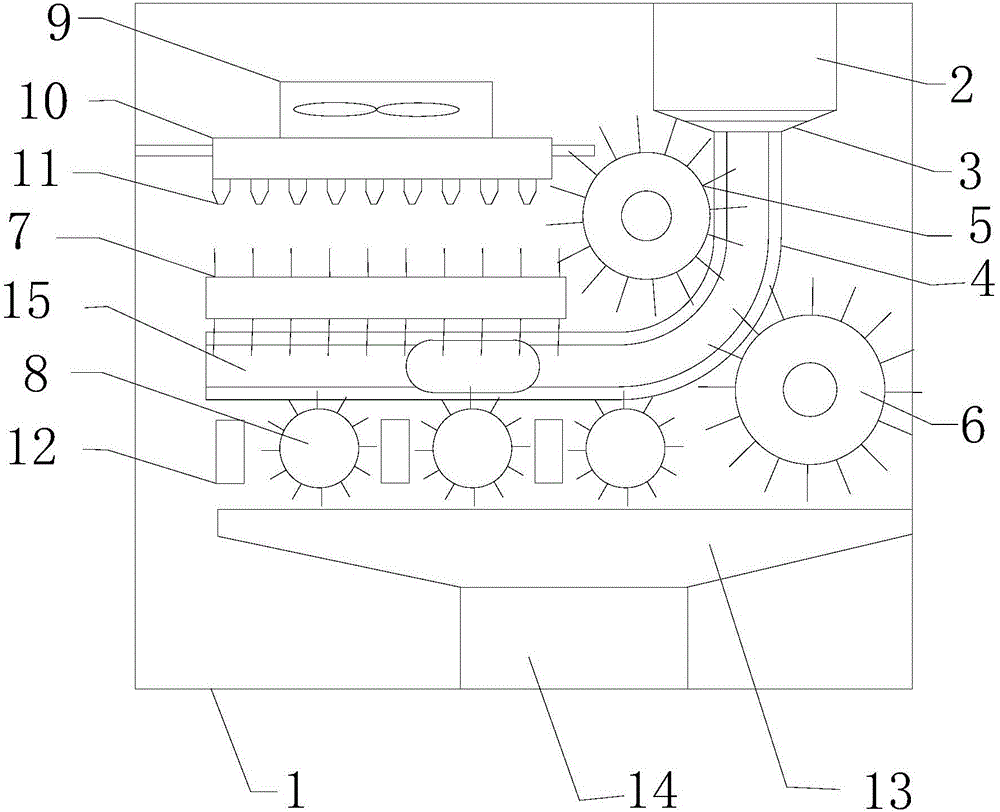

[0017] refer to figure 1 , a capsule polishing conveying device of the present invention, comprising a frame 1, a feeding trough 2, an oscillating feeder 3, a capsule conveying guide rail 4, an auxiliary feeding brush roller 5, an auxiliary transition brush roller 6, a rotating brush roller 7, Brush roller 8, ion blower 9, blowing plate 10, wind gathering nozzle 11, observation electric eye 12, dust suction bucket 13, dust suction motor 14, the top of the right side of the frame 1 is provided with a feed chute 2, the bottom The bottom of the trough 2 is connected with an oscillating feeder 3, and the bottom of the oscillating feeder 3 is connected with a capsule conveying guide rail 4, the shape of the capsule conveying guide 4 is an inverted L-shaped guide rail, and the right side of the capsule conveying guide 4 An auxiliary blanking brush roller 5 is arranged on the side of the position, an auxiliary transition brush roller 6 is arranged at the turning of the capsule convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com