Polishing and bevelling equipment capable of achieving bar autoroatation arrangement

A technology of grinding holes and automatic alignment, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of high labor cost, low grinding efficiency, poor operation stability, etc., to improve the alignment efficiency and high quality And the effect of high-efficiency grinding and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

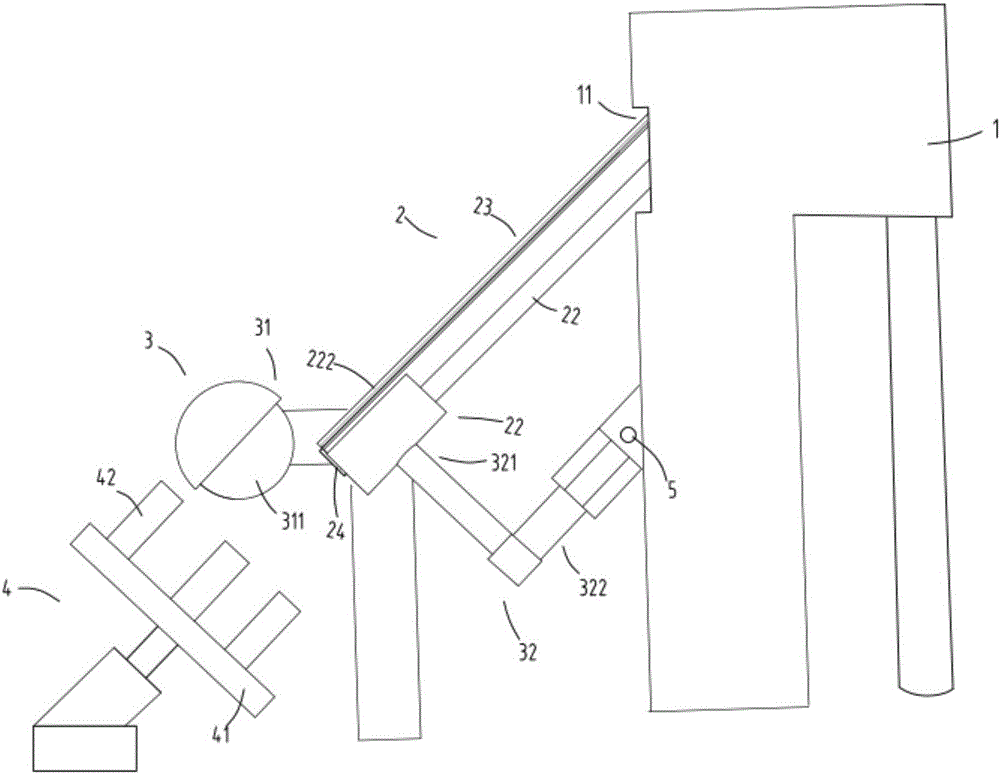

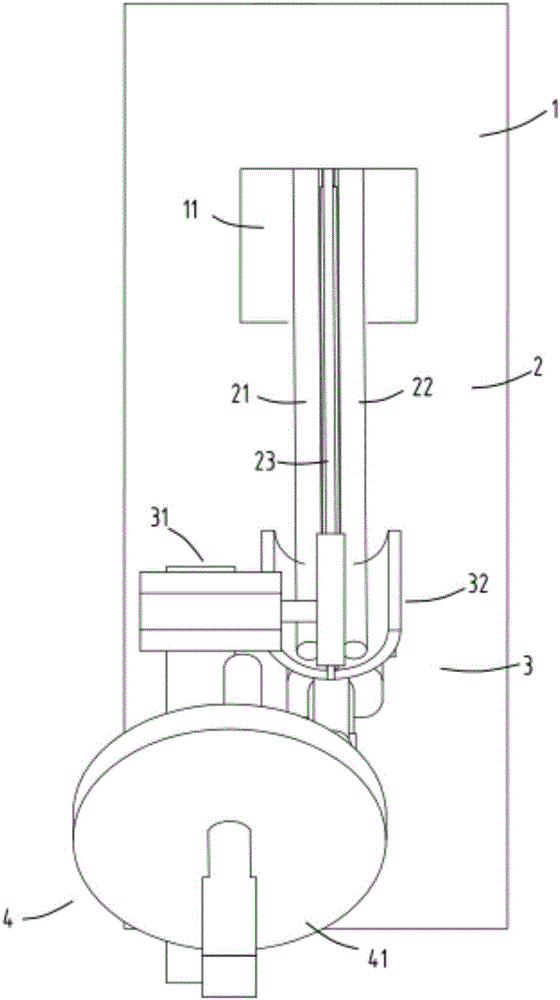

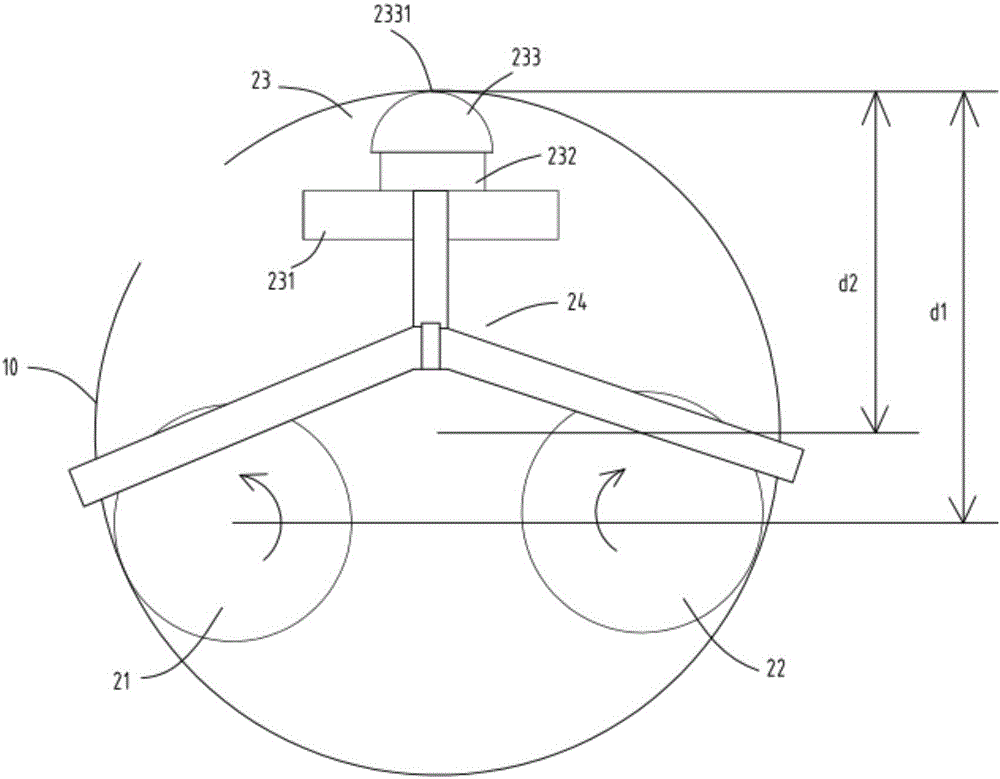

[0027] figure 1 It is a front view schematic diagram of a material rod self-rotating arrangement grinding breach equipment, figure 2 It is a side view schematic diagram of a material rod self-rotating arrangement grinding breach equipment, image 3 It is a schematic diagram of the structure of the automatic alignment device when the piston ring is hung on the rib a, Figure 4 It is a schematic diagram of the structure of the automatic arrangement device when the piston ring is hung on the pallet, Figure 5 Schematic diagram of the structure of the rotation arrangement device. Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a material rod self-rotating arrangement grinding breach equipment includes a breaching machine 1, an automatic arrangement device 2, a grinding device 3 and a collecting tray 4; the automatic arrangement device 2 is arranged at the material outlet 11 of the breaching machine 1 , used to neatly arrange the broken piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com