Efficient ladle baking device

A baking device and ladle technology, applied in the direction of casting melt container, metal processing equipment, casting equipment, etc., can solve the problem of incomplete absorption and utilization of waste heat in flue gas, complex structure of regenerative ladle baker, gas or Air ventilation is not smooth and other problems, so as to save gas, reduce safety hazards, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

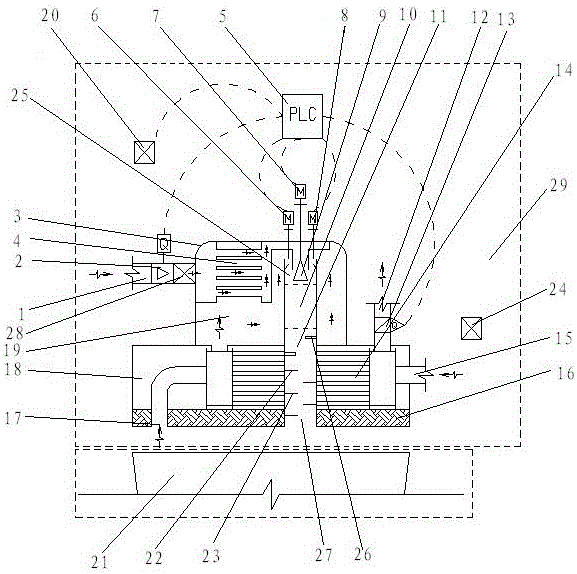

[0018] like figure 1 As shown, the present invention provides a high-efficiency ladle baking device 29, which covers the ladle 21, and a safety gap is left between the high-efficiency ladle baking device 29 and the ladle 21 according to relevant safety operation specifications.

[0019] The gas heat exchanger 4 is a gas-gas tube heat exchanger, the gas side of which is respectively connected to the gas pipeline 1 equipped with the flow meter 2 and the gas inlet of the burner, and the air side is placed in the air cavity in the roaster body 3. within 19.

[0020] The gas inlet of the burner is provided with a cone 9, which is connected to the vacuum chamber 25, the vacuum chamber 25 is connected to the mixed flow chamber 10, the mixed flow chamber 10 is connected to the combustion chamber 11, and the combustion chamber 11 is provided with a flame detector 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com