Oral cavity dental implant reconstructable guide plate and manufacturing method thereof

A manufacturing method and technology of dental implants, which are applied in the fields of dental implants, dentistry, and dental restorations, can solve problems such as non-compliance with requirements, material waste, etc., and achieve the effects of improved precision, convenient use, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

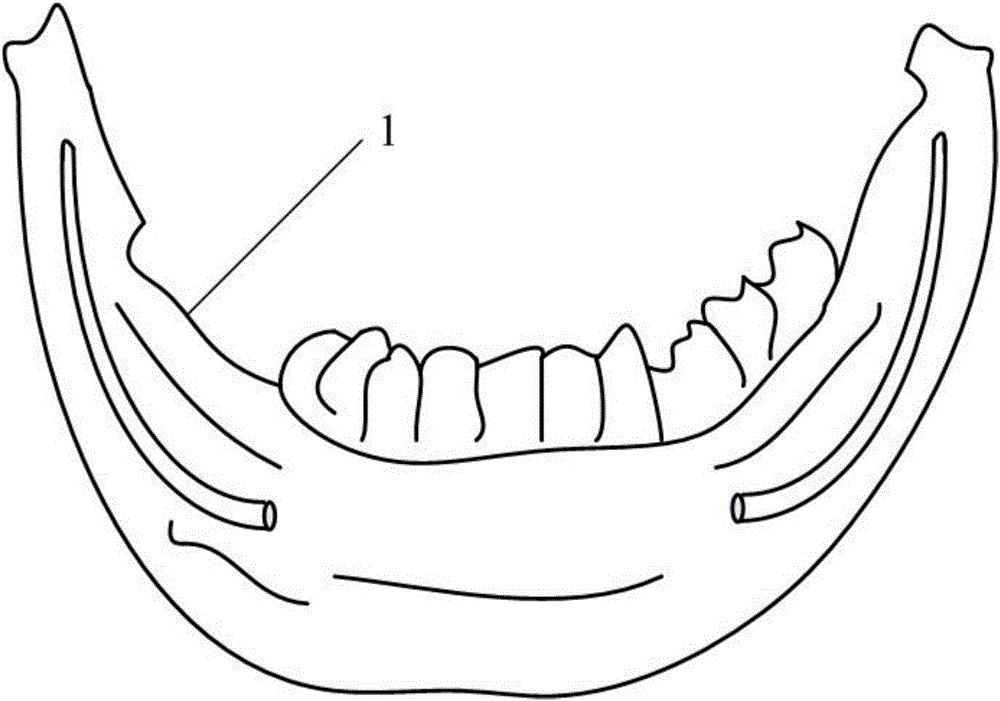

[0042] Such as figure 1 Shown is a schematic diagram of the reconstructed mandibular teeth and bone scan model of the patient, in figure 1 The middle edentulous area 1 is shown in the figure. When the CBCT data of the patient's jaw is collected, the data of the area will be collected.

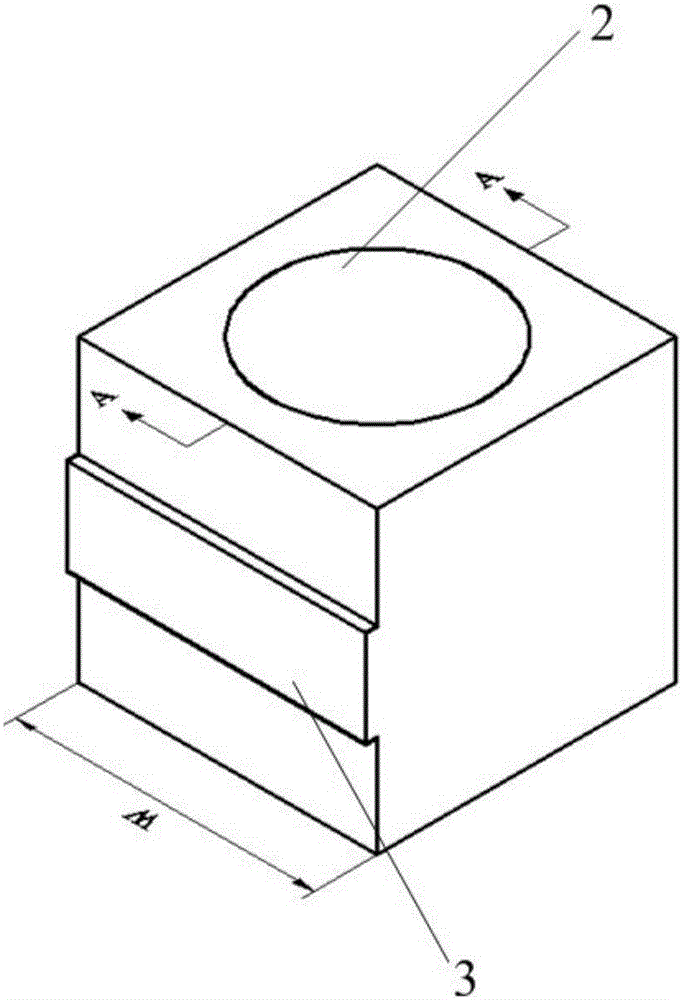

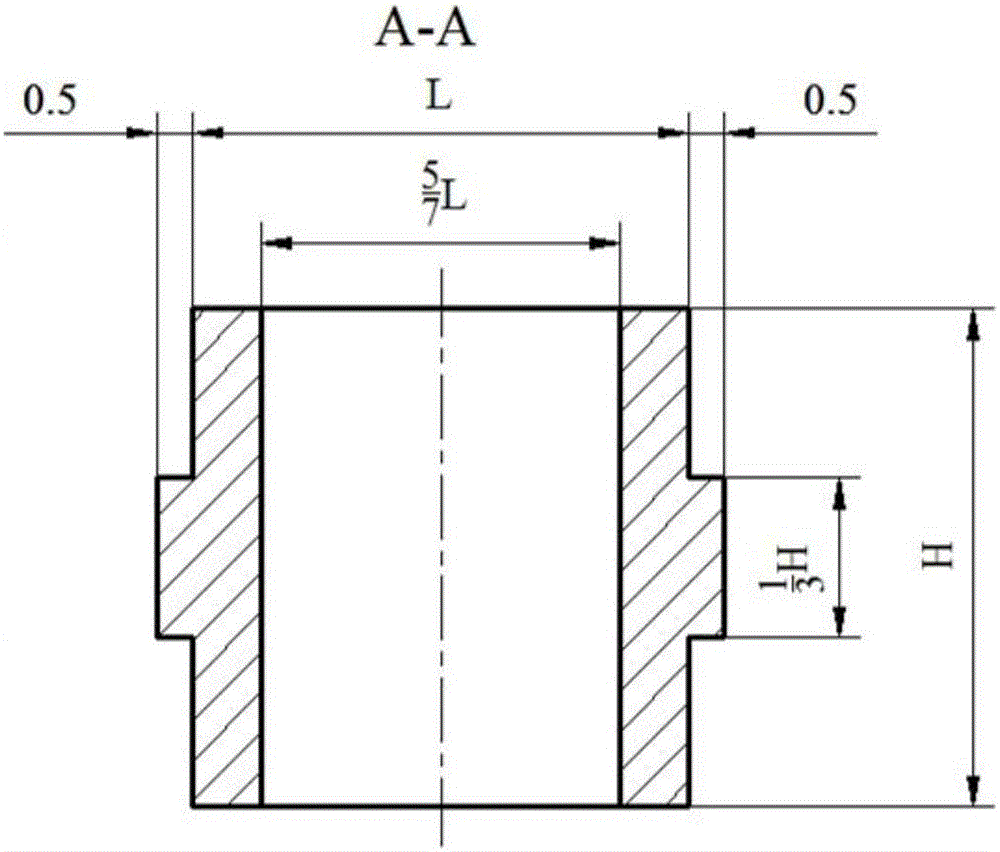

[0043] The structural characteristics of the dental implant reconfigurable guide plate are mainly composed of a movable drill template and a personalized substrate; the drill template is as follows figure 2 , image 3 As shown, it is a cuboid block with a cylindrical guide hole in the middle. The cylindrical guide hole 2 is located at the center of the cuboid block, corresponding to a standardized dental medical drill of a certain specification and size, and can be paired and combined with a standard drill. The hole is drilled on the alveolar bone; there is a buckle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com