Low-sugar artichoke and banana compound-flavor fruit granule pastry as well as preparation method and application thereof

A technology of thistle-banana and artichoke, which is applied in the field of low-sugar artichoke-banana compound flavored fruit cakes and preparation, can solve problems such as excessive oil, and achieve the effects of low sugar content, improved gastrointestinal tract and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

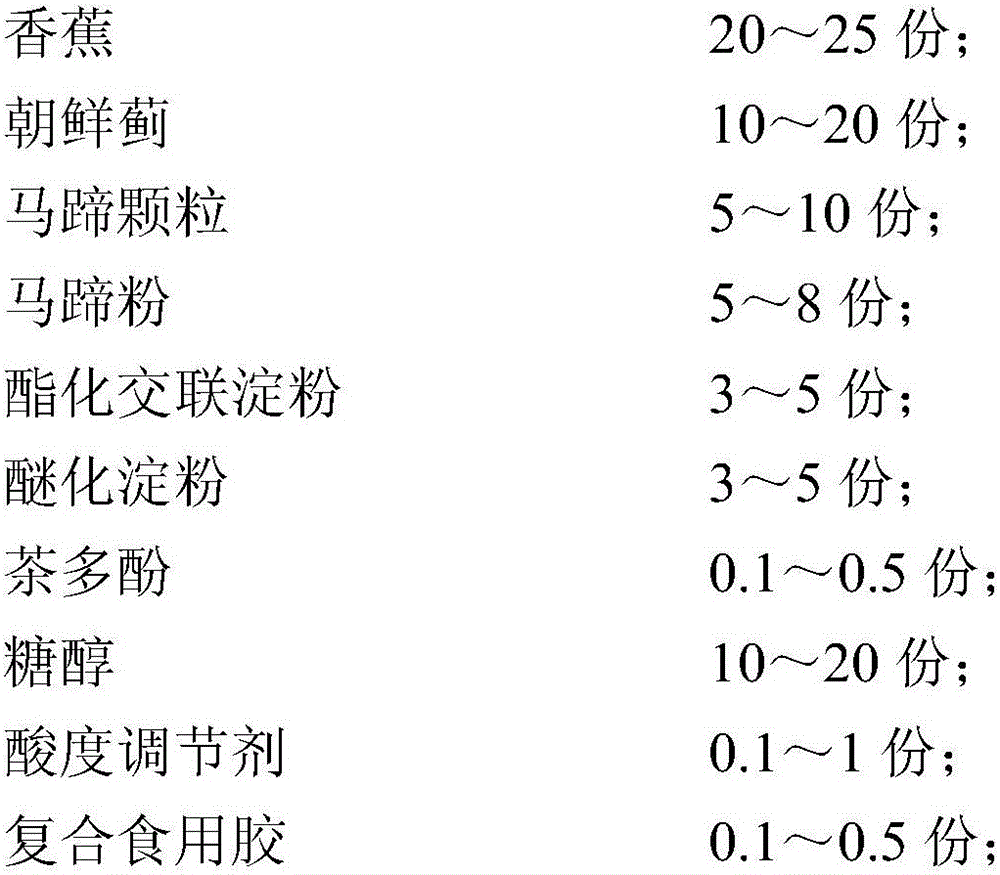

[0038] A low-sugar artichoke banana compound flavor fruit pastry, comprising the following components by mass parts:

[0039]

[0040] The preparation method of the low-sugar artichoke banana compound flavor fruit pastry comprises the following steps:

[0041] (1) Take 15 parts by mass of fresh artichoke (the mass ratio of feeding part and root is 2:1), clean, chop and beat, add cellulase, hemicellulase and acid protease, at a temperature of 45 ° C , under the condition of pH 4.5, enzymatic hydrolysis for 40 minutes, then high-temperature inactivation at 92°C for 8 minutes, and then adding 0.3 parts by mass of tea polyphenols and mixing evenly to obtain artichoke-tea polyphenols mixture; wherein, cellulase, hemicellulose The consumption of enzyme and acid protease is 0.1%, 0.1%, 0.2% of the total mass of artichoke;

[0042] (2) After peeling 23 parts by mass of bananas, they were first scalded at 100°C for 4 minutes, then mixed with the artichoke-tea polyphenol mixture pre...

Embodiment 2

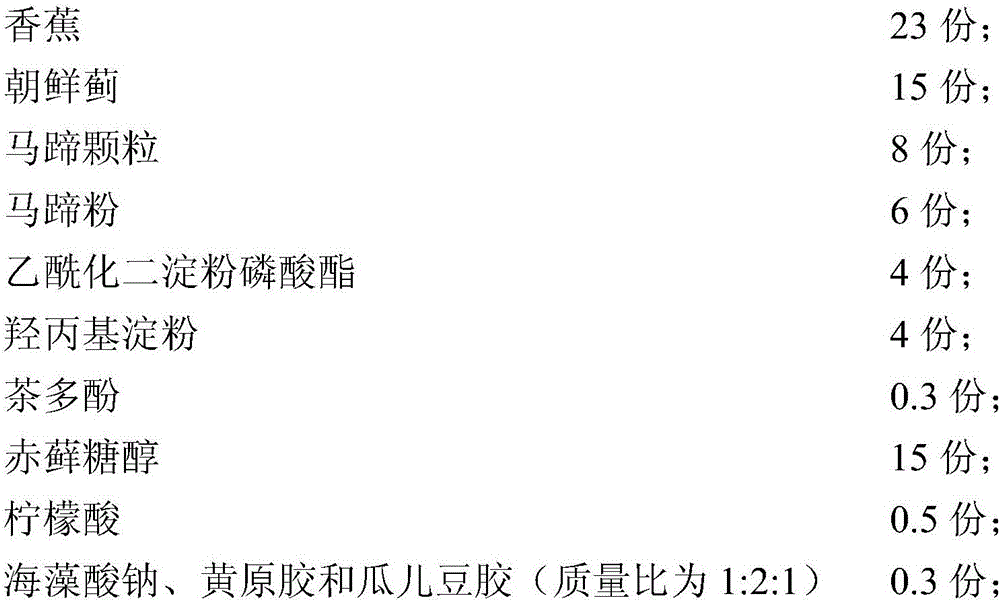

[0048] A low-sugar artichoke banana compound flavor fruit pastry, comprising the following components by mass parts:

[0049]

[0050] The preparation method of the low-sugar artichoke banana compound flavor fruit pastry comprises the following steps:

[0051](1) Take 20 parts by mass of fresh artichoke (the mass ratio of feeding part and root is 1:1), clean, chop and beat, add cellulase, hemicellulase and acid protease, at a temperature of 40 ℃ , under the condition of pH 5, enzymatic hydrolysis for 60 minutes, then high temperature inactivation at 90°C for 5 minutes, and then adding 0.1 parts by mass of tea polyphenols and mixing evenly to obtain artichoke-tea polyphenols mixture; wherein, cellulase, hemicellulose The consumption of enzyme and acid protease is 0.05%, 0.05%, 0.1% of the total mass of artichoke;

[0052] (2) After peeling 20 parts by mass of bananas, they were first scalded at 100°C for 3 minutes, then mixed with the artichoke-tea polyphenol mixture prepar...

Embodiment 3

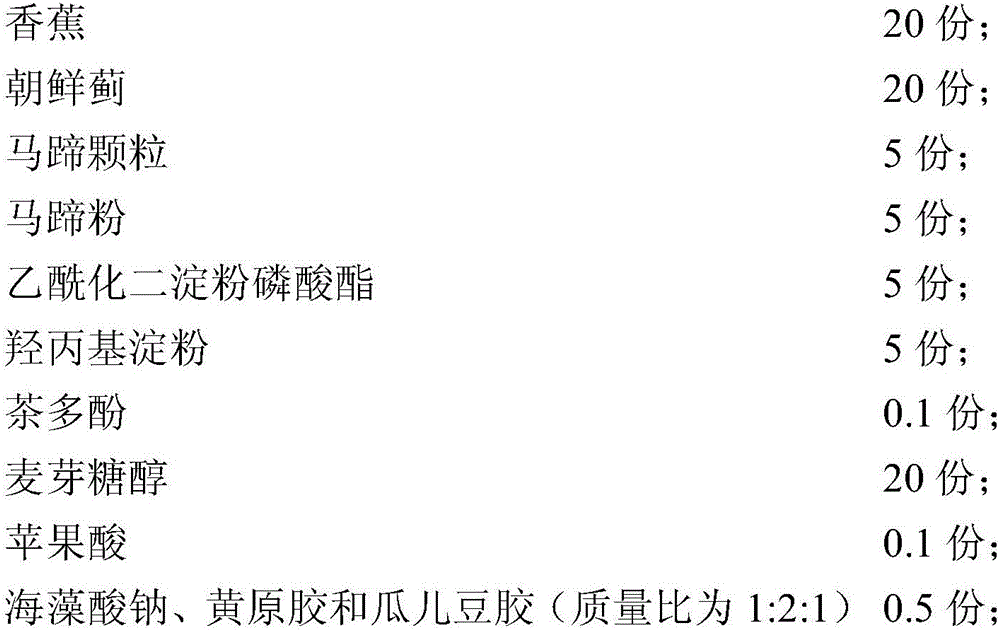

[0058] A low-sugar artichoke banana compound flavor fruit pastry, comprising the following components by mass parts:

[0059]

[0060] The preparation method of the low-sugar artichoke banana compound flavor fruit pastry comprises the following steps:

[0061] (1) Take 10 parts by mass of fresh artichoke (the mass ratio of feeding part and root is 3:1), clean, chop and beat, add cellulase, hemicellulase and acid protease, at a temperature of 50 ℃ , under the condition of pH 4, enzymatic hydrolysis for 30 minutes, then high-temperature inactivation at 95°C for 10 minutes, and then adding 0.5 parts by mass of tea polyphenols and mixing evenly to obtain an artichoke-tea polyphenols mixture; wherein, cellulase, hemicellulose The consumption of enzyme and acid protease is 0.2%, 0.2%, 0.3% of the total mass of artichoke;

[0062] (2) After peeling 25 parts by mass of bananas, they were first scalded at 100°C for 5 minutes, then mixed with the artichoke-tea polyphenol mixture pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com