Mixed fruit and vegetable fermented product and preparation method thereof

A technology for mixing fruits and vegetables and fermented products, which is applied in food preparation, food ingredients, and the functions of food ingredients. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

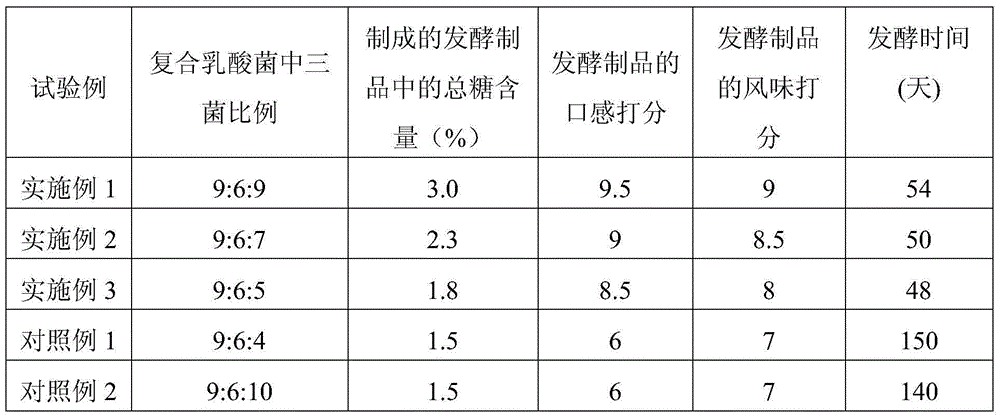

Examples

Embodiment 1

[0038] 1) Crushing mixed fruits and vegetables and preparing enzymatic hydrolyzate

[0039] Wash and crush mixed fruits and vegetables (including apples, pears, watermelons, sweet oranges, carrots, white radishes, cucumbers and tomatoes) to 40 meshes to obtain mixed fruit and vegetable liquid, add pectinase and cellulase to it for enzymatic hydrolysis, control The dosage of the pectinase is 2 units per gram of the mixed fruit and vegetable liquid, the dosage of the cellulase is 2 units per gram of the mixed fruit and vegetable liquid, and the enzymolysis is carried out at a temperature of 40° C. for 3 hours to obtain the enzymatic hydrolysis solution.

[0040] 2) First fermentation

[0041] Add carbon source, nitrogen source and inorganic salt to the enzymolysis solution, wherein the nitrogen source is collagen peptide; control in the enzymolysis solution, the addition of the carbon source is 5wt%, the nitrogen source The addition amount of said inorganic salt is 0.3wt%, and ...

Embodiment 2

[0051] 1) Crushing mixed fruits and vegetables and preparing enzymatic hydrolyzate

[0052] Wash and crush mixed fruits and vegetables (including apples, pears, watermelons, sweet oranges, carrots, white radishes, cucumbers and tomatoes) to 60 meshes to obtain mixed fruit and vegetable liquid, add pectinase and cellulase to it for enzymatic hydrolysis, control The dosage of the pectinase is 2.5 units per gram of the mixed fruit and vegetable liquid, the dosage of the cellulase is 2.5 units per gram of the mixed fruit and vegetable liquid, and the enzymolysis is carried out at a temperature of 45° C. for 2 hours to obtain the enzymatic hydrolysis solution.

[0053] 2) Expansion of bacterial strains

[0054] Leuconostoc enterococcus, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, and Lactobacillus plantarum were respectively cultured in the expansion medium at 35-37°C for 10-12 hours to orient the above strains optimization;

[0055] The composition o...

Embodiment 3

[0067] 1) Crushing mixed fruits and vegetables and preparing enzymatic hydrolyzate

[0068] Wash and crush mixed fruits and vegetables (including, by weight, 25 parts of apples, 25 parts of pears, 15 parts of watermelon, 5 parts of sweet orange, 15 parts of carrots, 5 parts of white radish, 5 parts of cucumber, and 5 parts of tomato) to 80 mesh , to obtain the mixed fruit and vegetable liquid, add pectinase and cellulase to it for enzymolysis, control the consumption of the pectinase to be 3 units per gram of the mixed fruit and vegetable liquid, and the consumption of the cellulase to be 3 units per gram of the mixed fruit and vegetable liquid 3 units, at a temperature of 50° C. for 4 hours to obtain an enzymatic hydrolysis solution.

[0069] 2) Expansion of bacterial strains

[0070] Leuconostoc enterococcus, Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, and Lactobacillus plantarum were respectively cultured in the expansion medium at 35-37°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com