Wave maker movement control method and system

A motion control system and motion control technology, used in fluid dynamics tests, testing of machine/structural components, measuring devices, etc., can solve the target waveform wave height error, affect the results, and it is difficult to meet the synchronization and real-time requirements of the wave-making system. Sexual requirements and other issues, to achieve the effect of fast wave-making speed, fast communication, and simple wave-making method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

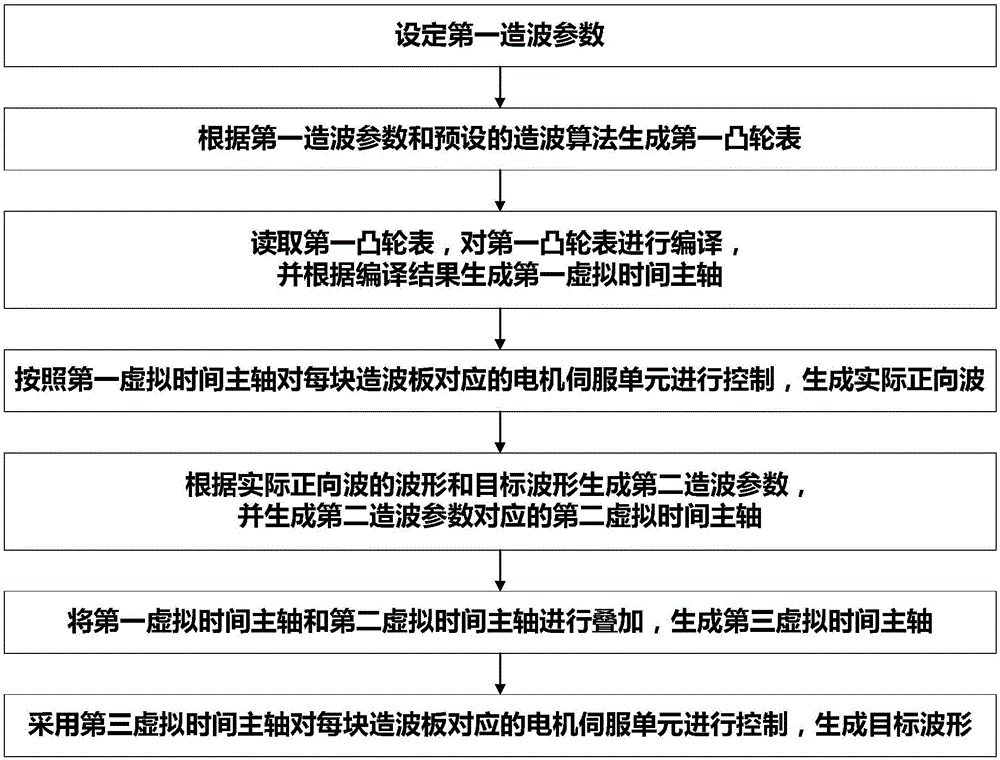

[0042] Such as figure 1 As shown, it is a schematic flow chart of a wave generator motion control method in Embodiment 1, including the following steps:

[0043]Step 1, setting the first wave-making parameters. In the present invention, the target waveform includes regular forward wave, irregular forward wave, regular oblique wave, irregular oblique wave, etc., and the first wave-making parameters are set according to different target waveforms. In this embodiment, the target waveform is a regular forward wave. The first wave-making parameters include wave period, wave height and wave number. The wave period is a regular wave movement time. The initial default is 1000ms, and it is incremented by 0.1s (100ms). is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com