Magnetic valve structure for clean tail gas

A solenoid valve and exhaust technology, which is applied in the valve shell structure, lift valve, valve details, etc., can solve the problems of the non-adjustable position of the solenoid valve, increase the processing cost, and the service life of the solenoid valve is not long, so as to ensure the exhaust gas treatment effect, improve Response sensitivity, effect of increasing release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

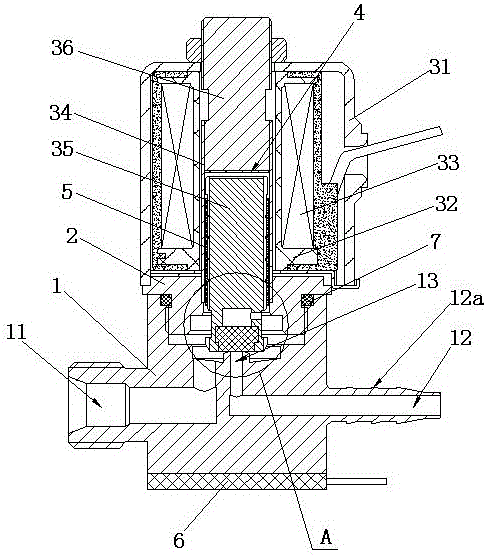

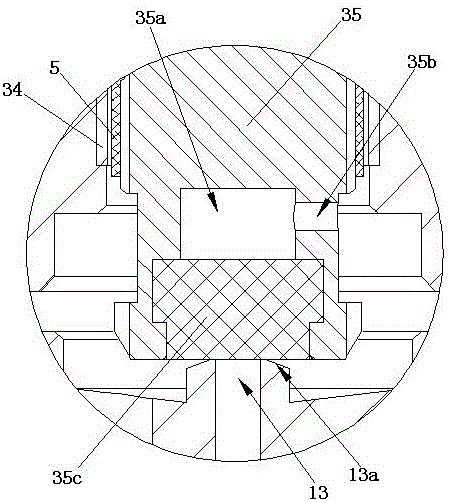

[0014] Such as Figure 1 to Figure 2 Shown is a schematic diagram of the structure of the present invention,

[0015] The reference signs are: valve body 1, air inlet 11, air outlet 12, convex ring 12a, air passage 13, cone 13a, valve cover 2, housing 31, coil support 32, coil 33, sleeve 34 , Moving iron core 35, pressure relief cavity 35a, pressure relief hole 35b, gasket 35c, static iron core 36, magnetic isolation sheet 4, wear sleeve 5, heating sheet 6, sealing ring 7.

[0016] Such as Figure 1 to Figure 2 As shown,

[0017] Based on the structure of a solenoid valve for cleaning exhaust gas, it includes a matching valve body 1 and a valve cover 2. The valve body 1 is provided with an air inlet 11 and an air outlet 12, and air is passed between the air inlet 11 and the air outlet 12 The passage 13 is connected, and the upper part of the valve cover 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com