Radially engaging coupling system

一种连接机构、啮合的技术,应用在径向啮合连接机构领域,能够解决人力成本超出、耗费大时间和人力等问题,达到结构简单、操作简便、利于推广的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

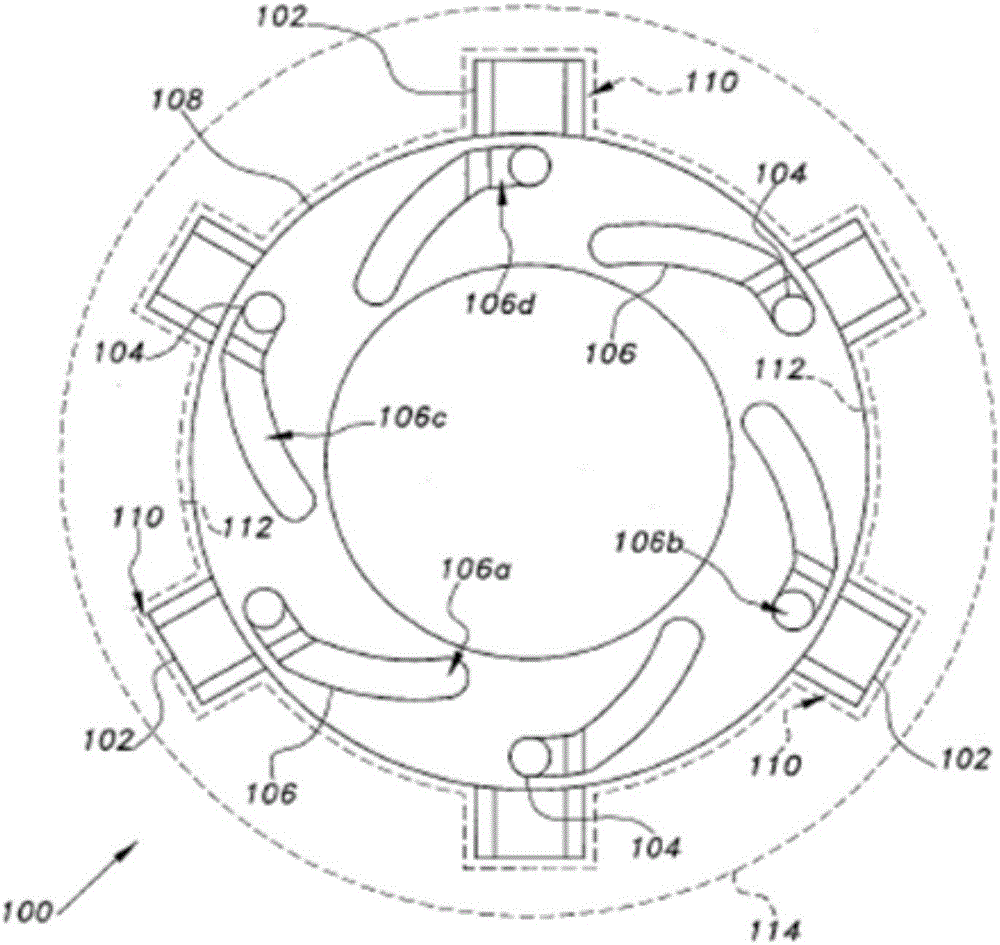

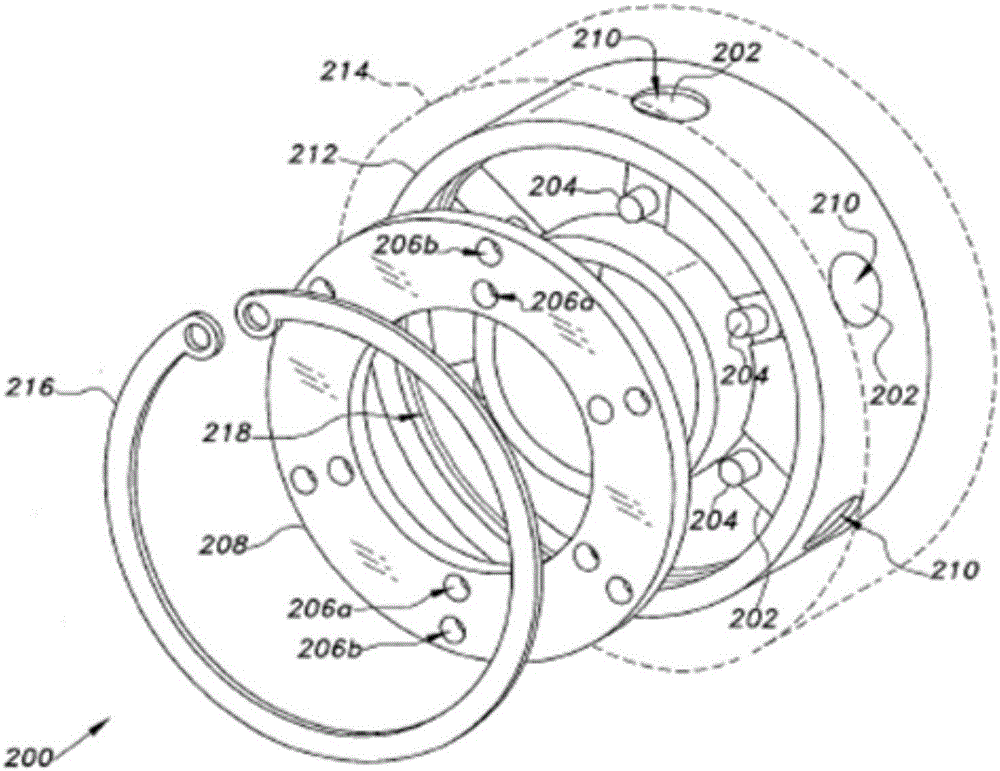

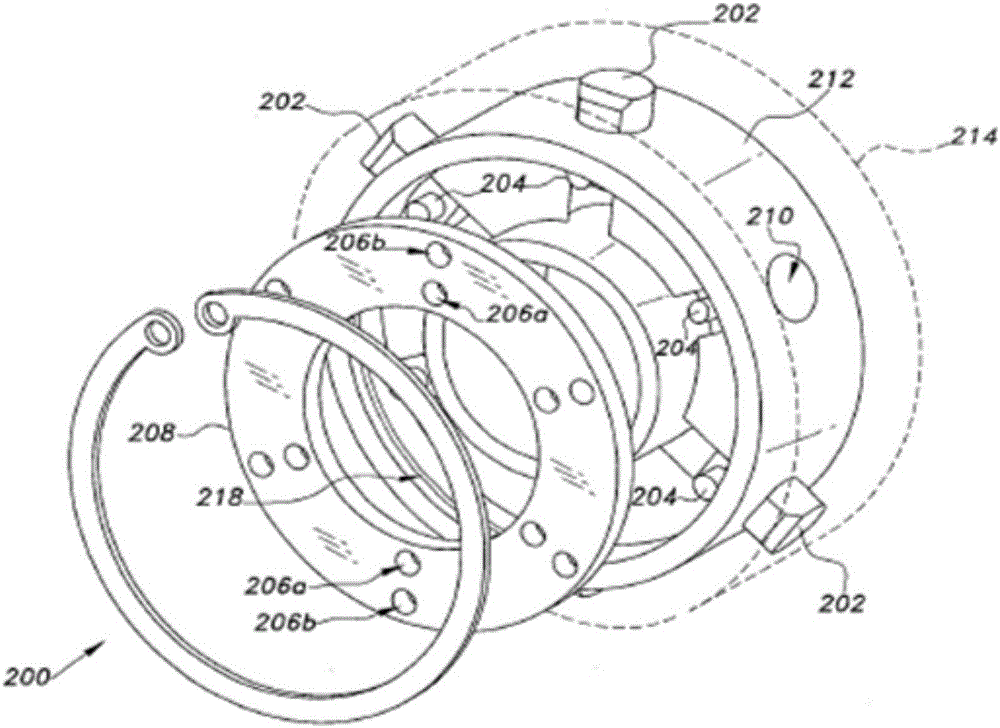

[0036]The radial engagement mechanism of the present invention comprises a number of embodiments, each radial engagement mechanism comprising at least one latch, preferably a plurality of latches; at least one alignment pin extending from each latch; and at least A positioning ring, the positioning ring has at least one inner cut-off positioning point and at least one outer cut-off positioning point, the number of inner cut-off positioning points and outer cut-off positioning points corresponds to the number of pins, and the positioning pin can be adjusted to be set in the positioning The inner cut-off positioning point or the outer cut-off positioning point of the ring, and with the position adjustment of the positioning pin, the radial extension or retraction of the pin can be realized; and a component coaxial with the positioning ring, which is attached to the positioning ring There is at least one bolt socket matching the bolt on the surface of the joint, and the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com