Front telescopic sleeve hydraulic cylinder for novel self-dumping trunk

A dump truck and telescopic technology, which is applied in the field of hydraulic cylinders, can solve the problems of high manufacturing cost, long maintenance man-hours, and maintenance difficulties, and achieve the effects of low manufacturing cost, short maintenance man-hours, and avoiding shaking or noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

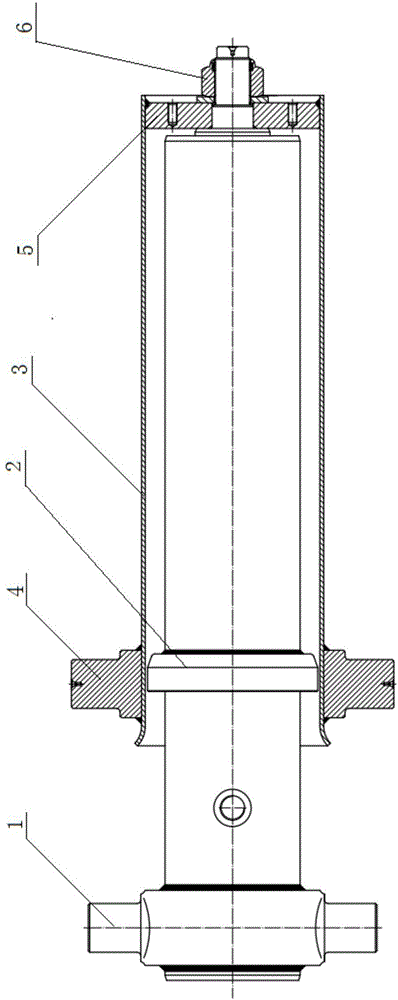

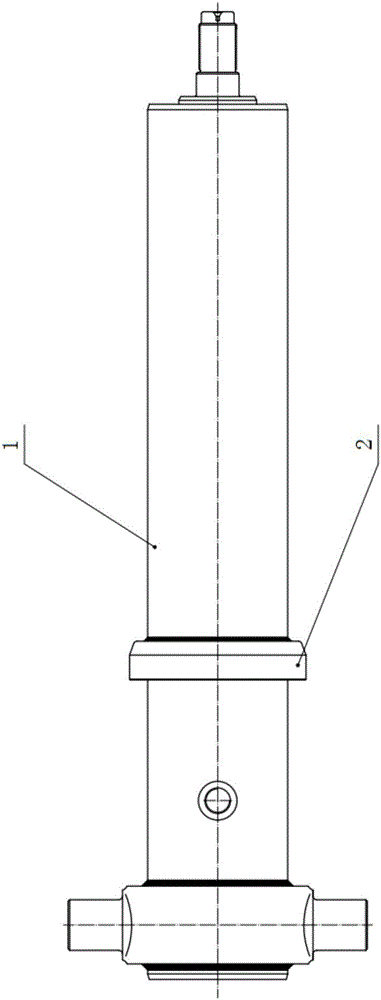

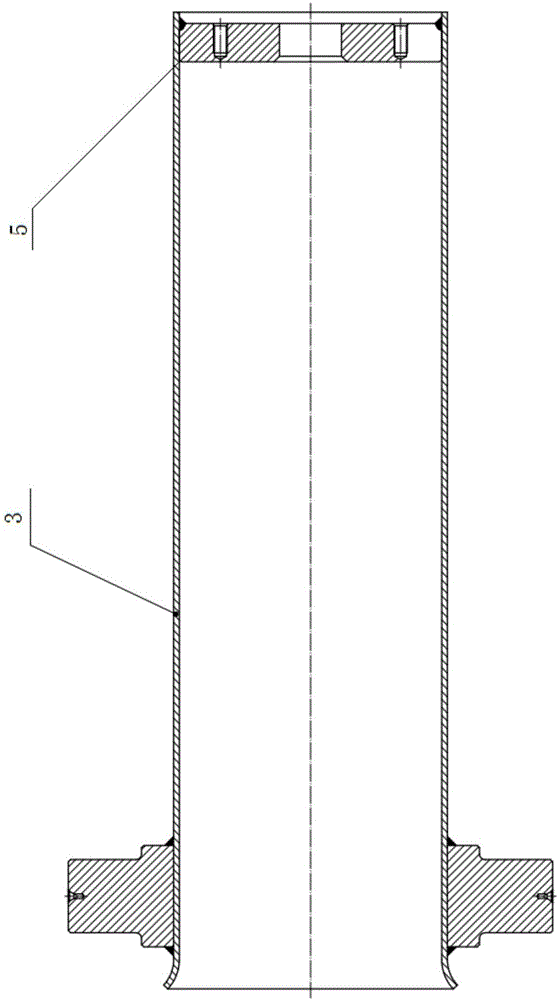

[0029] see Figure 6 and Figure 7 As shown, Embodiment 1 of the present invention provides a new front telescopic sleeve hydraulic cylinder for dump trucks, including a cylinder assembly 1 and an outer cover welding part 3, the front end of the outer cover welding part 3 has an opening, and the outer cover is welded The rear end of the part 3 is provided with an end cover 5, and the outer wall of the outer cover welding part 3 is provided with an upper hinge shaft 4 near the front end; the cylinder assembly 1 is inserted into the outer cover welding part 3 through the opening, and the cylinder assembly The end of 1 passes through the end cover 5 and is locked by the large nut 6 outside the end cover 5; the outer wall of the cylinder assembly 1 is provided with a support ring 2, and the support ring 2 is equally divided into at least three support rings. Nail 7. The support nail 7 is slightly higher than the support ring, and when the oil cylinder shakes, the outer cover wel...

Embodiment 2

[0032] see Figure 6 and Figure 8 As shown, the structure of the second embodiment of the present invention is basically the same as that of the first embodiment, and the difference is that the support nail 7 is a wave bead screw, and the wave bead screw includes a screw body 74, and the middle part of the screw body 74 is provided with a groove 73, A spring 72 is installed in the groove 73 , and a steel ball 71 is arranged on the end of the spring 72 close to the port of the groove 73 . By setting the ball screw as a structure of spring 72 and steel ball 71, the ball screw can automatically expand and contract under the pressure of the cylinder assembly 1, avoiding the shaking or noise of the cylinder assembly 1 due to the gap . In addition, since the friction relationship between the ball bead screw and the cylinder assembly 1 is rolling friction, compared with the existing sliding friction, it effectively reduces the friction with the cylinder assembly, reducing the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com