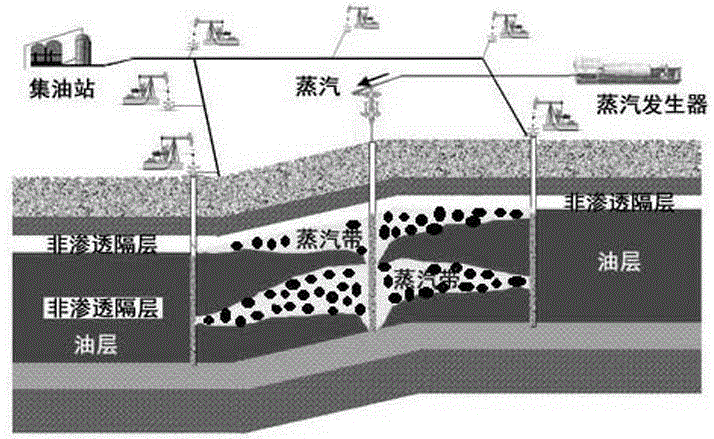

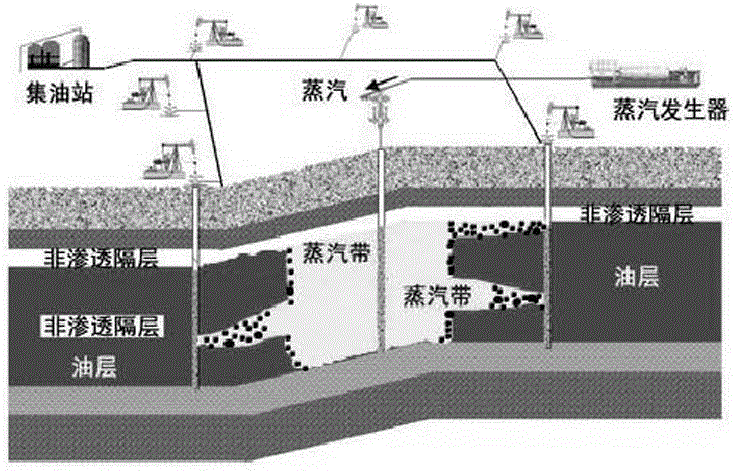

Technical method of steam channeling and plugging of thick oil

A technology for thermal recovery and steam channeling of heavy oil, which is applied in the direction of production fluid, earthwork drilling, sealing/isolation, etc. It can solve the problem of not completely blocking the channel of steam channeling, and not considering the leakage of the plugging agent injected into the channel of steam channeling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: The technical method of steam channeling plugging in the thermal recovery of heavy oil is carried out according to the following steps: in the first step, the cottonseed hulls with a mass percentage of solid particles of 30% to 60% and a mass percentage of 40% are Stir the water to 70% evenly and squeeze it into the steam channel with a high-pressure pump; in the second step, after the first step is completed, continue to mix wood chips with a mass percentage of 30% to 60% and a mass percentage of 40% Stir the water to 70% evenly and squeeze it into the steam channeling channel with a high-pressure pump; in the third step, after the second step is completed, squeeze in cement slurry to block the steam channeling channel; in the fourth step, squeeze in clean water to replace the cement slurry completely Enter the channel of steam channeling; the fifth step, close the well and wait for 48 hours to 72 hours. When in use, because sawdust and cottonseed hulls a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com