Prefabricated self-resetting energy consumption support

An energy-consuming support and self-reset technology, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve the problems of high repair cost, waste of steel, inconvenient construction, etc., to reduce construction period and repair cost. , the effect of reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

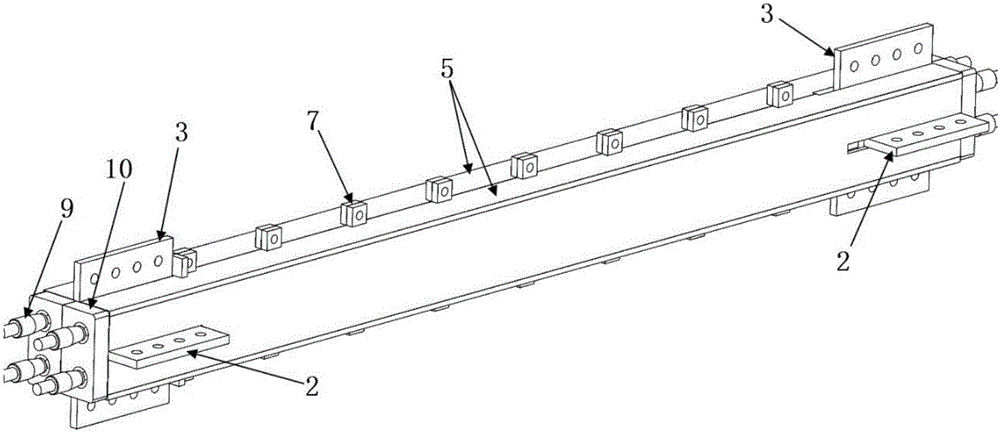

[0034] as attached figure 1 And attached figure 2 As shown, the assembly process of the present invention can be completed in the factory. In the factory, the self-resetting mechanism is first assembled on the shell mechanism, and after the tension cable is anchored with an anchor, after the assembly with the energy-dissipating core mechanism is completed, the shell mechanism is fastened with bolts. The upper housing connects the lugs. Then at the construction site, it is only necessary to fasten the protruding wide and narrow connecting plates and the frame with bolts.

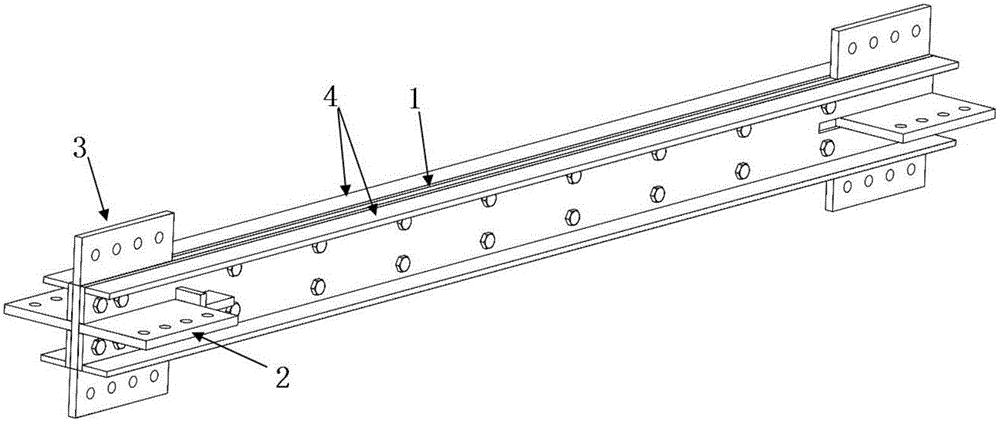

[0035] as attached image 3 And attached Figure 4 As shown, the assembly process of the energy-dissipating core mechanism of the present invention is completed in the factory. When assembling, attention should be paid to the matching direction of the fixed channel steel and the steel plate, that is, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com