Carding device for textile fabric

A technology for textile fabrics and hair combs, which is applied in textiles and papermaking, fabric surface trimming and roughening, etc., can solve the problems of polluting the working environment, falling, and trouble for processing workers, and achieves the advantages of popularization and application, simple and practical structure, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

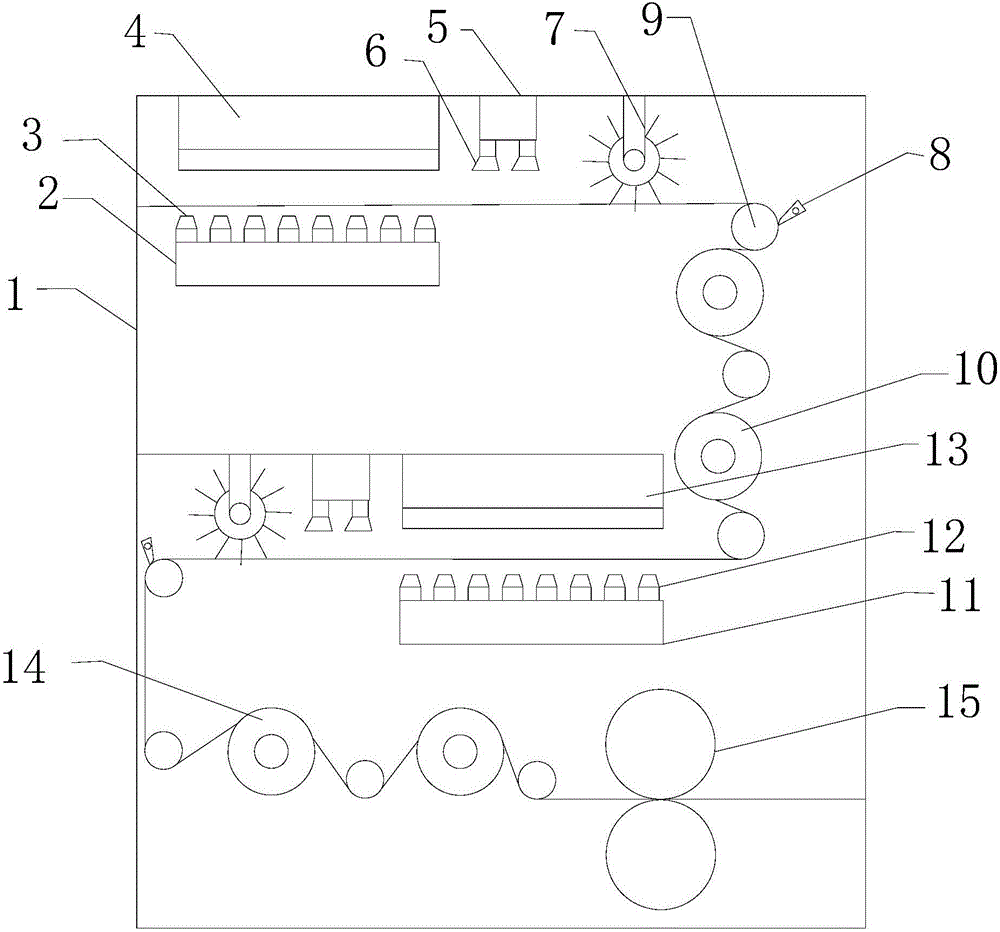

[0017] see figure 1 , a textile fabric carding device of the present invention, comprising a frame 1, a first air spray plate 2, a first air spray head 3, a first dust suction plate 4, a water spray plate 5, an atomized water spray head 6, and a grooming brush roller 7 , hair comb 8, transition roller 9, the first ironing roller 10, the second air jet plate 11, the second air jet head 12, the second dust suction plate 13, the second ironing roller 14, shaping pressure roller 15, the The top of the frame 1 is provided with a first air jet plate 2, and the first air jet plate 2 is provided with a plurality of first air jet heads 3, and above the first air jet plate 2 is provided with a first dust suction plate 4. The right side of the dust suction plate 4 is provided with a water spray plate 5, and the water spray plate 5 is provided with some atomized water nozzles 6, and the right side of the atomized water nozzle 6 is provided with a grooming brush roller 7, and the hair groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com