Locking device for rotating shaft of washing machine

A technology for locking devices and rotating shafts, which can be used in washing devices, other washing machines, textiles and papermaking, etc. It can solve the problems of difficult axial clearance control, non-detachable, difficult to control shrinkage ratio, etc., and achieves a good limit effect and easy loading Lightweight, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

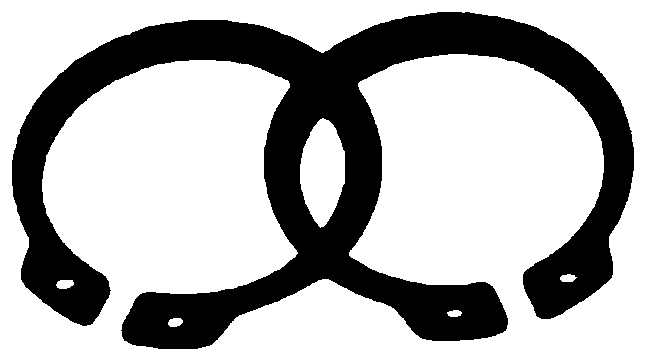

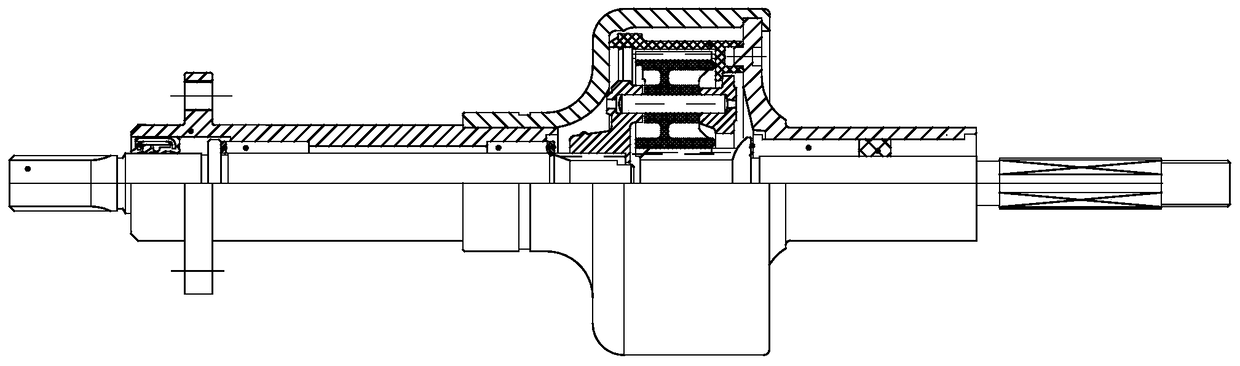

[0024] combine Figure 5-7 , is a schematic diagram of the principle structure of an embodiment of the locking device for the rotating shaft of a washing machine according to the present invention, which includes a body 1, which is provided with protruding teeth 2 that are evenly distributed outwards, and the connection between the protruding teeth 2 and the body is provided There is a circle of grooves 3 .

[0025] More specifically, the convex tooth 2 is square; the edge 4 of the outer end of the convex tooth 2 is set on a circle concentric with the center; the corners of the convex tooth 2 are rounded; The width of the protruding teeth 2 is less than or equal to the distance between adjacent protruding teeth 2; the locking device is molded from a metal material through punching and then integrally heat-treated.

[0026] Preferably, the hardness of the locking device after heat treatment is HRC47-53.

[0027] The locking device for the rotating shaft of the washing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com