Composite energy storage system energy optimization and allocation method of electric automobile

An electric vehicle and composite energy storage technology, applied in the field of energy distribution of composite energy storage systems, can solve the problems of poor distribution effect and long running time, and achieve the effects of reducing power range, short running time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

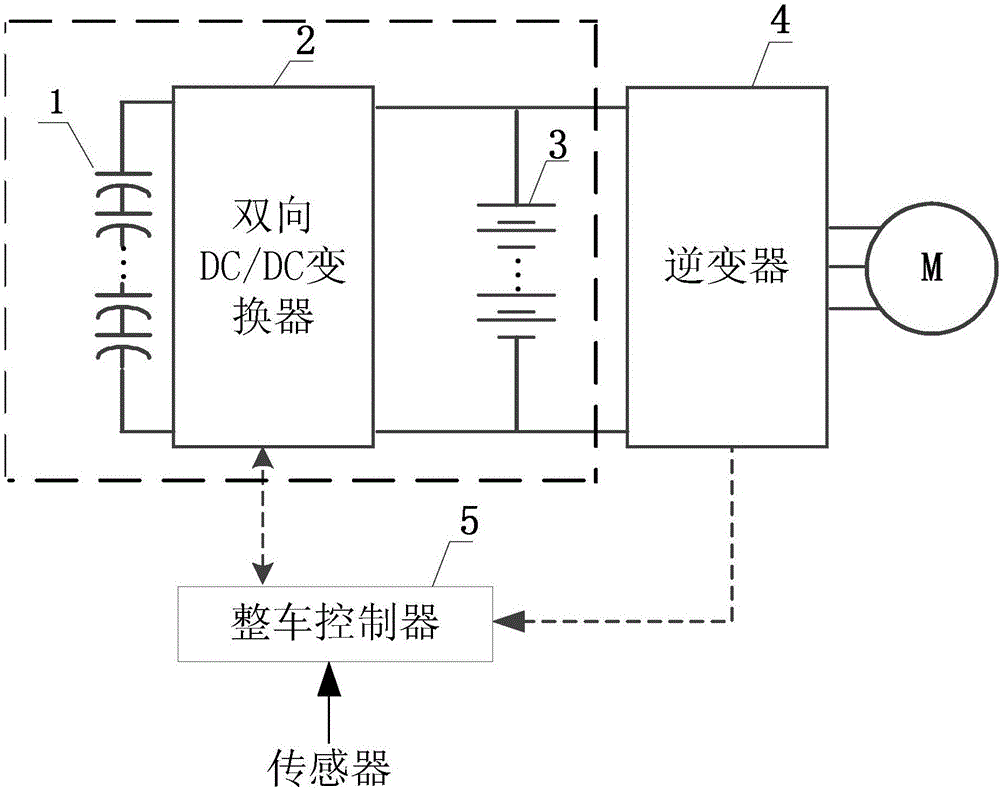

[0042] Specific implementation mode one: see figure 1 Describe this embodiment, the energy optimal distribution method of the electric vehicle composite energy storage system described in this embodiment, the composite energy storage system includes a supercapacitor bank 1, a bidirectional DC / DC converter 2, a battery pack 3, and an inverter 4 and vehicle controller 5,

[0043] After the supercapacitor pack 1 and the bidirectional DC / DC converter 2 are connected in series, they are connected in parallel with the battery pack 3 to form an energy storage system; the energy storage system supplies power to the motor of the electric vehicle through the inverter 4; the vehicle controller 5 It is used to collect the data information of the electric vehicle motor, and is also used to control the bidirectional DC / DC converter 2;

[0044] The allocation method includes the following steps:

[0045] Step S1, the output power P of the battery pack 3 b , the output power P′ of the supe...

specific Embodiment approach 2

[0055] Specific implementation mode two: see figure 1 This embodiment is described. The difference between this embodiment and the energy optimal distribution method of the electric vehicle hybrid energy storage system described in the first embodiment is that the convex optimization method is used in the step S1 to generate the optimized total output of the electric vehicle. The specific process of the comparison table of power and output power of supercapacitor group 1 is as follows:

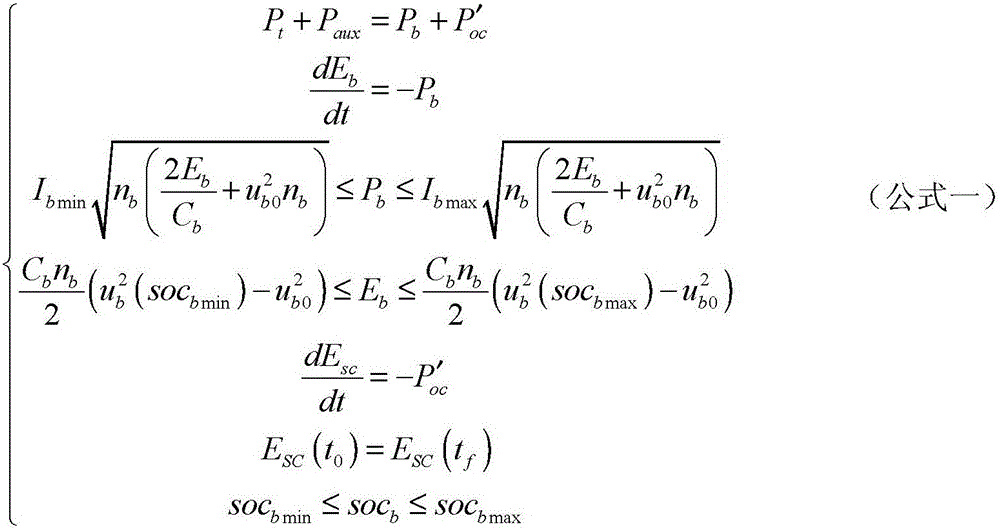

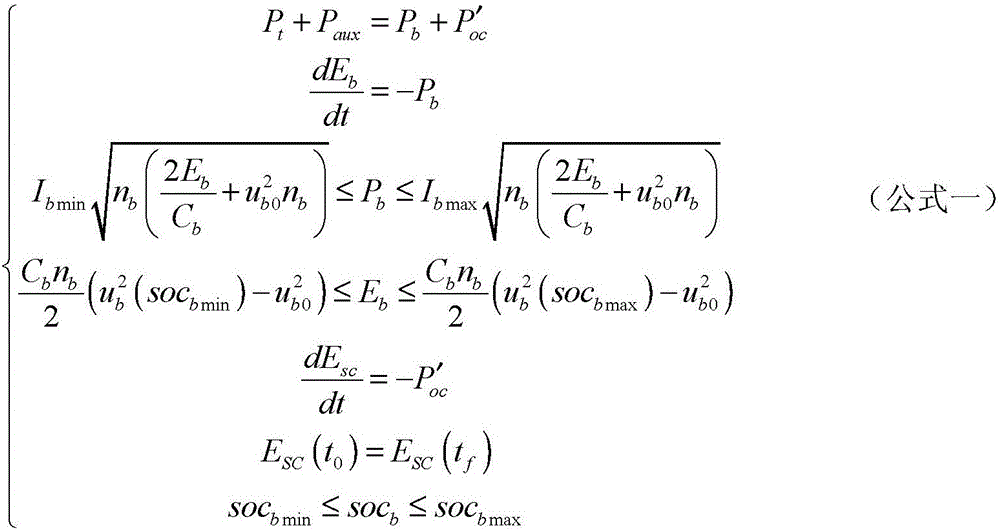

[0056] Step S11, define the objective function of convex optimization as Convex optimization constraints are shown in Formula 1;

[0057]

[0058] Among them, t 0 Indicates the start time of a cycle condition, t f Indicates the end time of a cycle working condition, t is a time variable;

[0059] P aux is the auxiliary power of the electric vehicle,

[0060] I b min is the minimum output current of the battery cell, I b max The maximum current output by the battery cell,

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com