Single different diameter multi-product dense medium cyclone

A dense medium cyclone and multi-product technology, applied in the direction of the cyclone device, etc., can solve the problems of complex installation, large equipment footprint, and low control of the density of the feeding suspension, so as to achieve compact equipment structure and easy installation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, the purpose is only to better understand the content of the present invention, so the examples given are not intended to limit the content of the present invention.

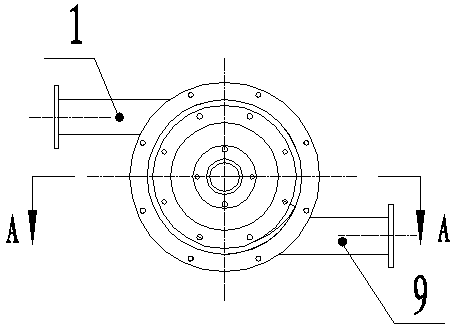

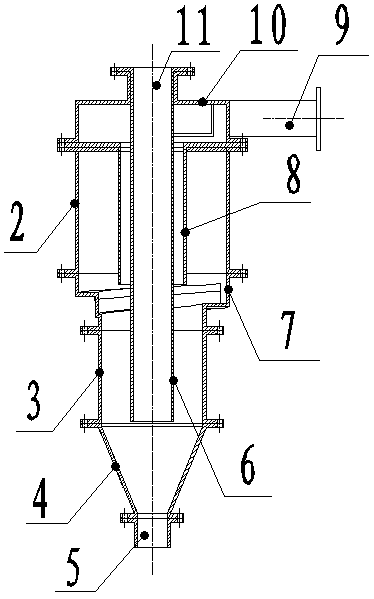

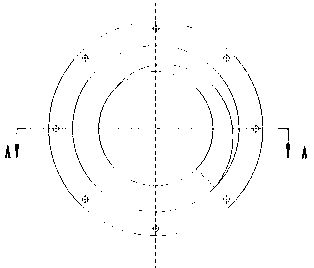

[0019] see Figure 1 to Figure 4 , a single different-diameter multi-product (three-product) dense medium cyclone, the exterior consists of a cylindrical section 2, a spiral reducing pipe 7, a second cylindrical section 3, and a conical section 4 arranged in sequence from top to bottom Docking, the inner overflow pipe 6 and the outer overflow pipe 8 are arranged inside; the diameter of the first cylindrical section 2 is larger than the diameter of the second cylindrical section 3, and the two are connected as a whole through the spiral reducing pipe 7, and the upper end of the first cylindrical section 2 is connected The feed port is equipped with a feed port 1, the bottom of the second cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com