Reaction type gangue crushing and separating tester

A separation test and crushing device technology, applied in grain processing and other directions, can solve the problems of hidden radiation sources, small sorting ability, difficult identification and other problems, and achieve the effect of simple and compact structure, small volume and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0011] The impact type coal gangue crushing and separating test machine of the present invention includes a mechanical part and a control part.

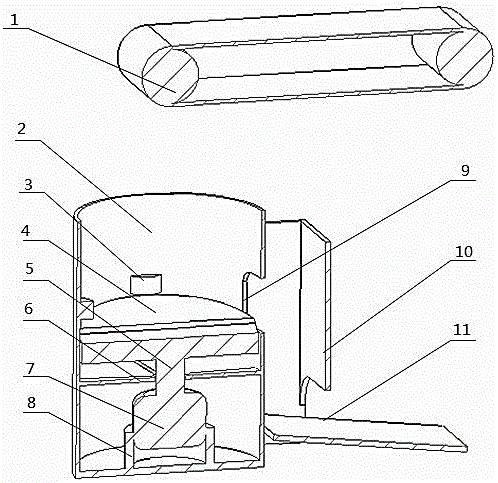

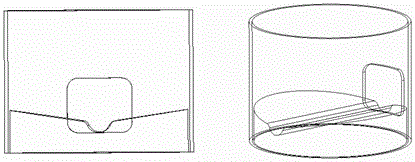

[0012] The mechanical part includes a belt conveyor and a drum accelerated crushing device. The drum accelerated crushing device includes a drum shell 2, an auxiliary crushing block 3, and an accelerating runner 4. There is a material ejection port 9 on one side of the shell, and the accelerating runner 4 passes through the connecting The shaft 5 is connected with the variable frequency speed regulating motor 7, the connecting shaft 5 is fixed by the fixed frame 6, the motor 7 is fixed on the casing 2 by rubber soft 8 sets, the material is transported into the casing 1 by the belt conveyor 1, and falls on the acceleration On the runner 4, the acceleration runner 4 rotates at an accelerated speed driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com