High-technology ceramic pump body used for pump and manufacturing method thereof

A manufacturing method and technology of ceramic pumps, applied in the direction of manufacturing tools, ceramic molding machines, pumps, etc., can solve the problems of ceramic blocks falling off, not resistant to wear, leakage, etc., to improve reliability, prolong pump casing life, seal good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

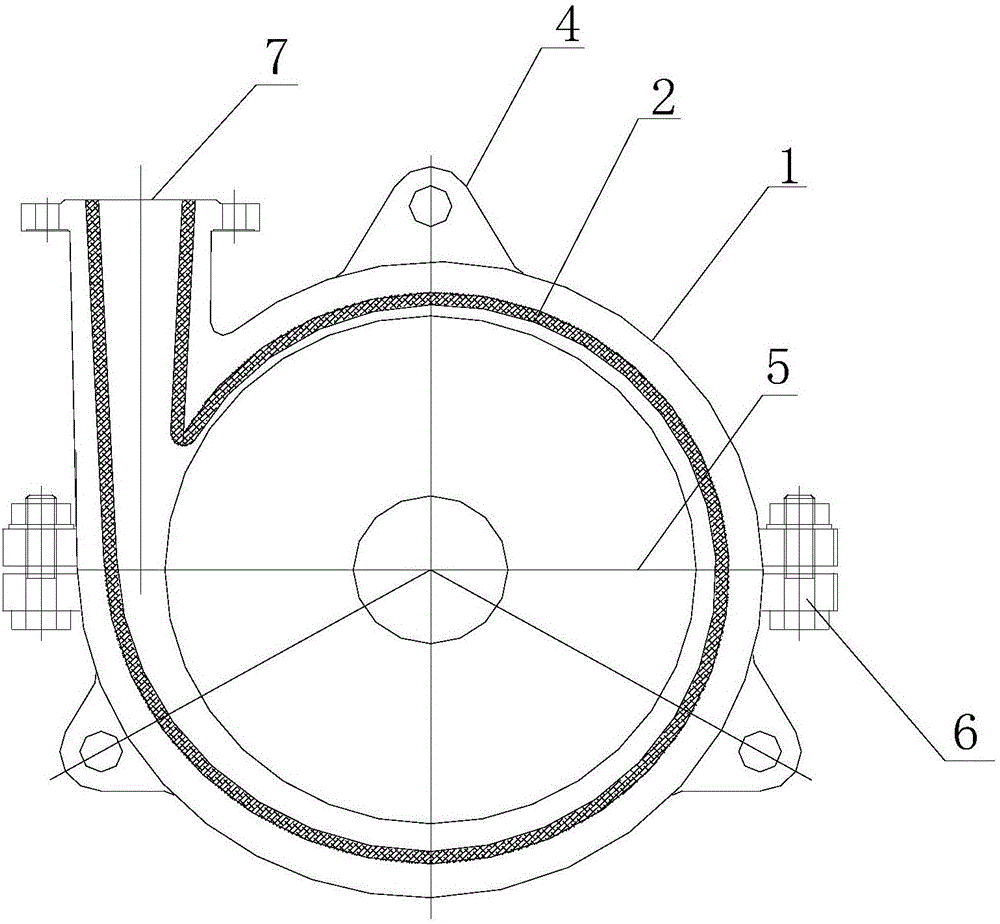

[0021] Such as figure 1 , figure 2 As shown, a high-tech ceramic pump body for a centrifugal pump, the pump body is composed of a ceramic lining and a metal shell, wherein the ceramic lining is composed of two semicircular ceramics, and the ceramic lining is provided with an inlet and outlet , the metal shell is also composed of two semicircular metal parts, the structure is matched with the ceramic, the ceramic and the metal are bonded by high-temperature glue, the two semicircular parts are connected and closed by bolts, and the joint surface is flexible sealed to form a whole pump body.

[0022] The manufacturing method of the high-tech ceramic pump body includes the following steps:

[0023] (a) Manufacture of ceramic lining

[0024] 1) Design the structural size of the ceramic lining according to the working conditions, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com