Method for extracting coal bed gas from circulating pulse type low temperature freeze-thawed anti-reflection coal

A technology of cycle pulse and coalbed gas, which is applied in the direction of mining fluid, mining equipment, earth drilling and mining, etc., can solve the problems of object structure damage and achieve the effect of improving the efficiency of anti-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

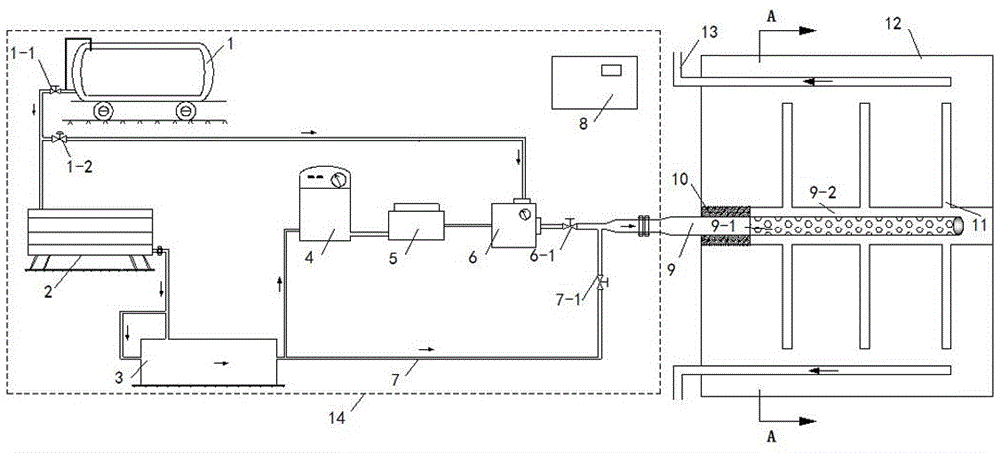

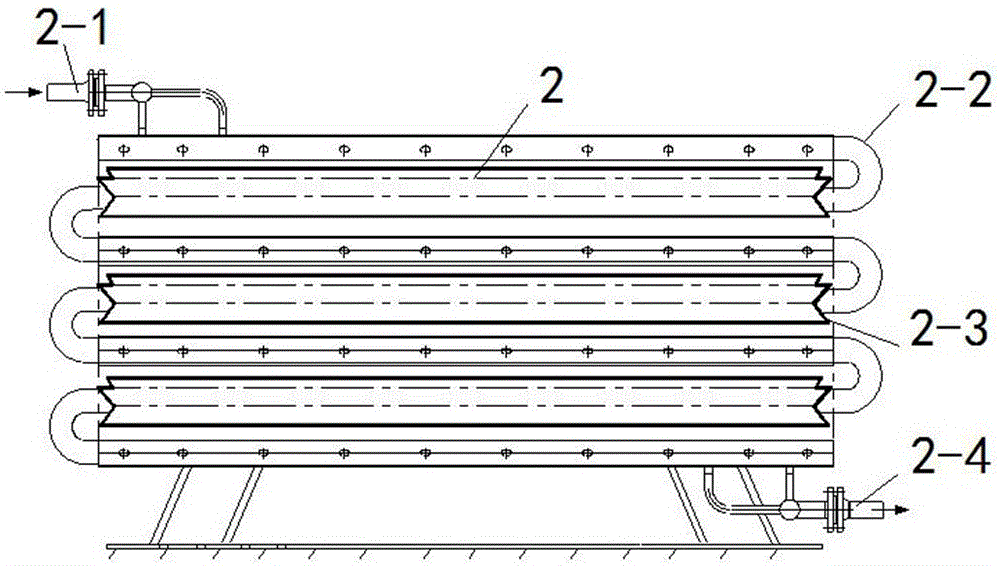

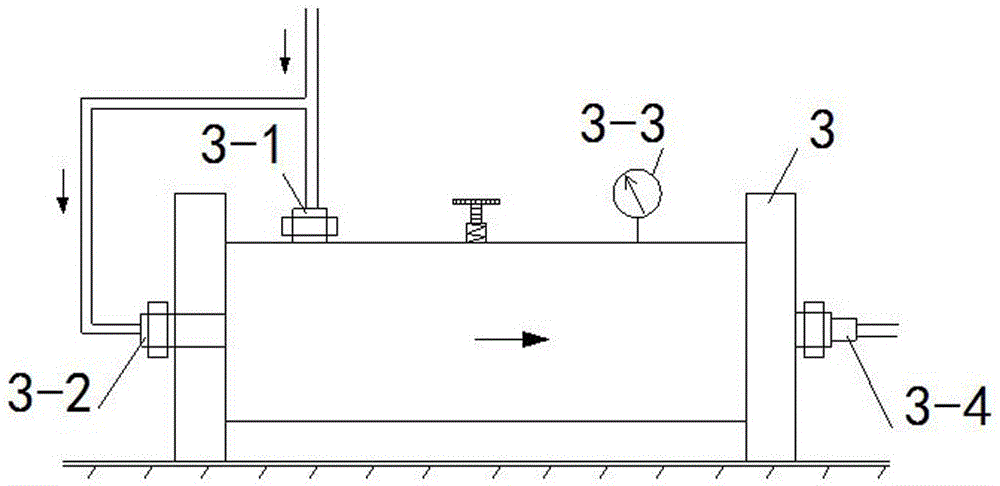

[0032] Embodiment one, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, in the coal seam 12, the water jet slotting equipment 8 is used to construct the drill holes 9-2 and multiple rows of guide slots 11 in the coal seam. There are two guide slots 11 in every row of guide slots, and one end of the guide slots communicates with the borehole. The two guide slots respectively extend to the left and right sides of the borehole in the coal seam along the vertical direction to the borehole. A coalbed methane extraction borehole 13 is provided at the outer end of the guide slot. A coalbed methane extraction borehole 13 is respectively set up on the left and right sides of the borehole 9-2.

[0033] Then the main pipe 9 is arranged in the borehole 9-2, and the conventional method is used for high-pressure sealing, and the length of the grouting sealing section 10 is 5-20 m. Then the coal seam 12 is subjected to freeze-thaw fracturing and permeability enhancement ...

Embodiment 2

[0037] Such as Figure 4 , Figure 5As shown, the low-level roadway 15-1 penetrates the upward drilling and pulsatingly circulates the liquid low-temperature medium to freeze-thaw and enhance the drainage to extract pressure-relieving gas, which is basically the same as the first embodiment. The different parts are mainly for injecting pulsating liquid low-temperature medium from the lower roadway 15-1 to the freeze-thaw anti-reflection area in the upper coal seam 12. The depth of the main pipe 9 should penetrate the rock formation into the coal seam 12. The coal seam is 10m~100m. The remaining parts are all the same as in Embodiment 1, and the same parts are omitted.

Embodiment 3

[0039] Such as Figure 4 , Figure 6 As shown, the high-level roadway 15-2 is drilled down through layers and circulated to inject liquid low-temperature medium to freeze-thaw, increase permeability, extract pressure-relieving gas, and it is basically the same as the first embodiment. The different parts are mainly to inject liquid low-temperature medium into the freeze-thaw anti-permeability area in the lower coal seam 12 from the high-level roadway 15-2 through the layer. The depth of the main pipe 9 should penetrate the rock layer into the coal seam 12. According to the thickness of the coal seam, the main pipe 9 should drive into the coal seam 10m~100m. The remaining parts are all the same as in Embodiment 1, and the same parts are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com