Aqueous acrylate heat-conduction coating material and preparation method thereof

A technology for water-based acrylic and thermally conductive coatings, applied in the field of coating chemistry, to prevent performance degradation, broad industrial application prospects, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

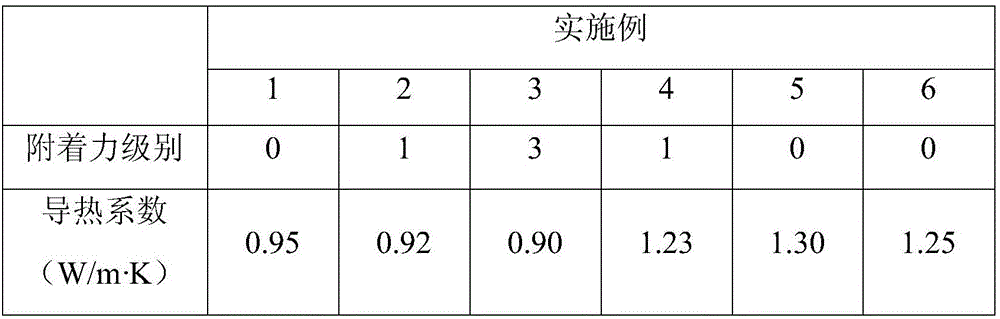

Examples

Embodiment 1

[0027] Mix 60 parts of water-based acrylate emulsion, 30 parts of thermally conductive filler alumina, and 10 parts of water and add them to a high-speed disperser for stirring. The thermally conductive filler is spherical alumina with a particle size of 9-11 μm and a class with a particle size of 1.8-2.0 μm Spherical alumina is mixed according to the mass ratio of 3:1, and the control speed is 1500rpm. After stirring for 1 hour, add 0.05 parts of defoamer emulsified silicone oil, 2.5 parts of film-forming agent dodecyl alcohol ester and 5 parts of adhesion promoter τ- Mercaptopropyltrimethoxysilane, control the speed at 1500rpm, continue to stir for 1h, after mixing evenly, it will be a thermally conductive coating.

Embodiment 2

[0029] The difference from Example 1 is that the adhesion promoter is changed to aminopropyltrimethyloxysilane, and the addition amount is 5 parts.

Embodiment 3

[0031] The difference from Example 1 is that no adhesion promoter is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com