A self-stirring sewage treatment purification tank

A technology for sewage treatment and purification tanks, which is applied in the directions of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of narrow application areas and limited scope of use of treatment facilities and other problems, to achieve the effect of small footprint, increased sewage treatment capacity, and beneficial to purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

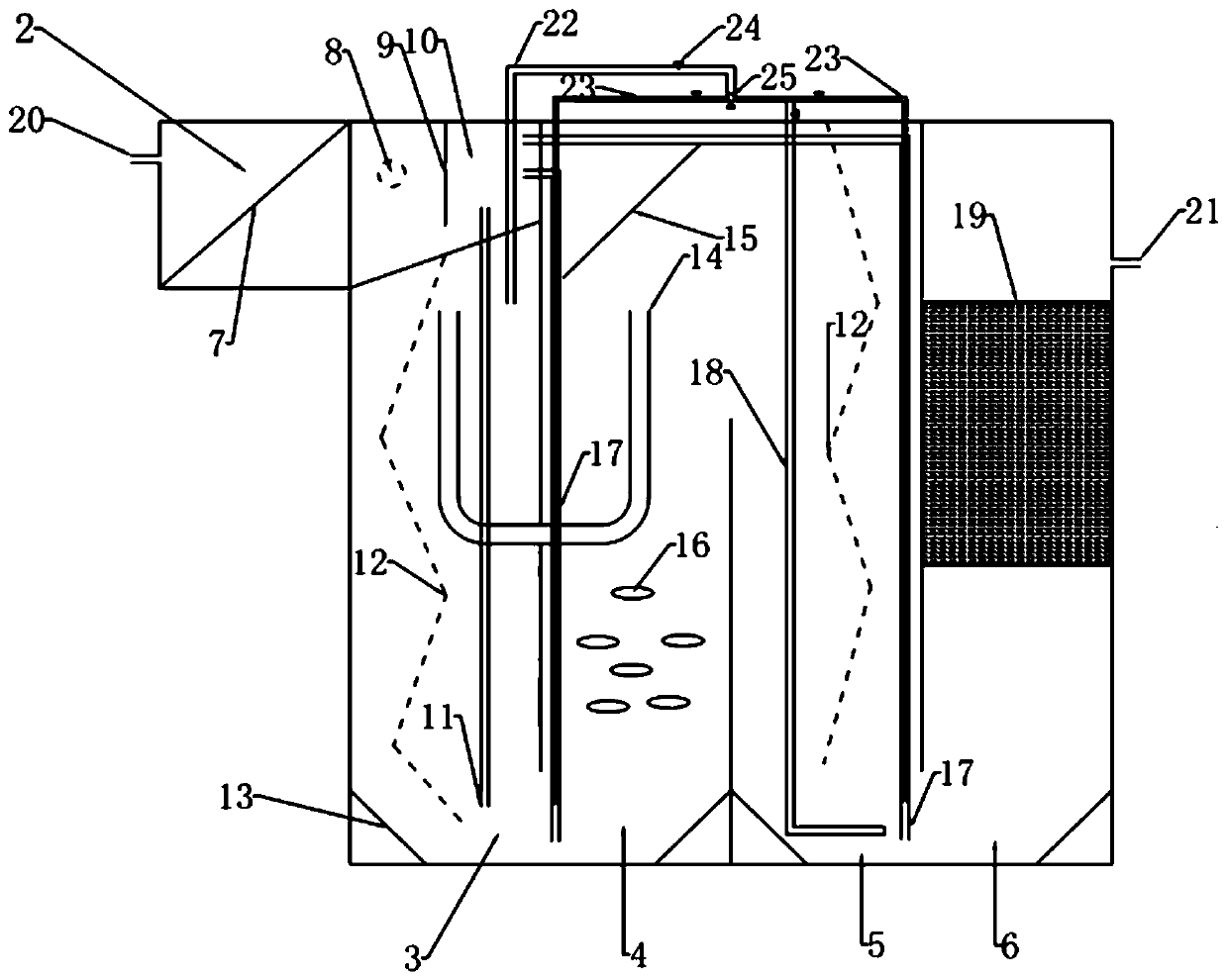

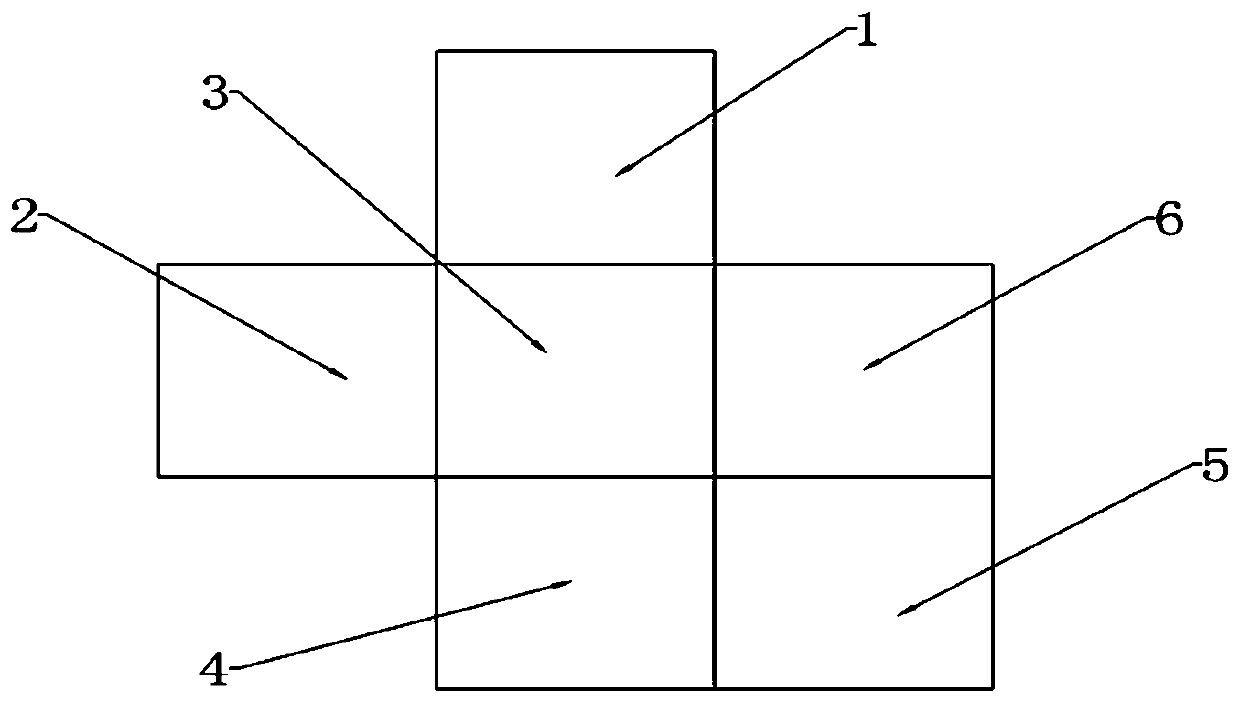

[0021] Such as figure 1 As shown, the expanded structure schematic diagram of the self-stirring sewage treatment purification tank of the present invention is provided, figure 2 The top view of the self-stirring sewage treatment purification tank of the present invention is provided. The purification tank of the present invention is composed of a water inlet tank 2, an oil separation tank 1, a first grid tank 3, a second grid tank 4, a third grid tank 5, and a fourth grid tank. Groove 6, water inlet pipe 11, air pump 25, blowing pipe 22, aeration pipe 18, mud discharge pipe 17 and mud discharge air pipe 23, the first, second, third and fourth lattice grooves shown are according to matts Shape layout, the lower part of the first grid groove 3 communicates with the second grid groove 4, the upper part of the second grid groove 4 communicates with the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com