Automatic positioning equipment for body-in-white stamping part

A technology for automatic positioning and sheet metal parts, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inconvenient production, complex structure, limited vehicle models, etc., to reduce equipment and labor investment costs, high precision, and positioning short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

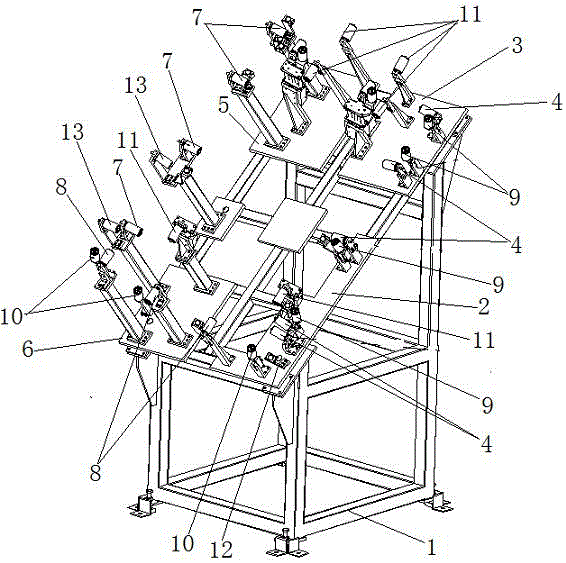

[0013] like figure 1 As shown, this embodiment provides an automatic positioning device for sheet metal parts of the body-in-white, including a frame 1, the top of the frame 1 is inclined from front to back; and the first support plate 3; the right side of the top of the reference plate 2 and the first support plate 3 are respectively provided with three first support wheel mechanisms 4 and two first support wheel mechanisms 4 that slide longitudinally; the frame 1 The upper left corner and the lower left corner of the top are respectively provided with a second support plate 5 and a third support plate 6, and the second support plate 5, the third support plate 6 and the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com