Method for using novel rotary wing-shape heat-accumulation-type organic waste gas purification device

A technology of organic waste gas and rotary airfoil, which is applied in the direction of chemical instruments and methods, combustion methods, combined devices, etc., can solve the problems of increasing the complexity of the purification device system, increasing investment and operating costs, and uneconomical recycling methods. Produces secondary pollution, convenient and quick to use and maintain, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

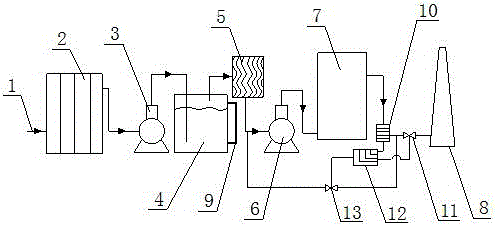

[0015] For specific examples, see figure 1 , the use method of a new type of rotary airfoil heat storage type organic waste gas purification device, including intake pipe 1, filter 2, booster fan 1 3, water washing tank 4, dryer 5, booster fan 2 6, rotary airfoil heat storage Formula burner 7, emptying tower 8 and valve two 13, its steps are:

[0016] (1) First, the organic waste gas to be purified enters the filter 2 from the intake pipe 1, and the filter 2 can remove dust and solid particles in the organic waste gas, and the organic waste gas treated by the filter 2 is pressurized Driven by the fan one 3, it enters the washing tank 4, the washing tank 4 can remove water-soluble impurities in the organic waste gas, and the organic waste gas passes through the washing tank 4 to form a preliminary purified organic waste gas;

[0017] (2) The preliminarily purified organic waste gas after passing through the washing tank 4 enters the drier 5, and the drier 5 can dehydrate and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com