Superfine crystal pure titanium oral micro-implant and preparation method thereof

A technology of ultra-fine-grained pure titanium and micro-implantation, which is applied in prosthetics, dental implants, and medical science, can solve the problems of low osseointegration strength of micro-implants, reduce the risk of fracture, increase the osseointegration area, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

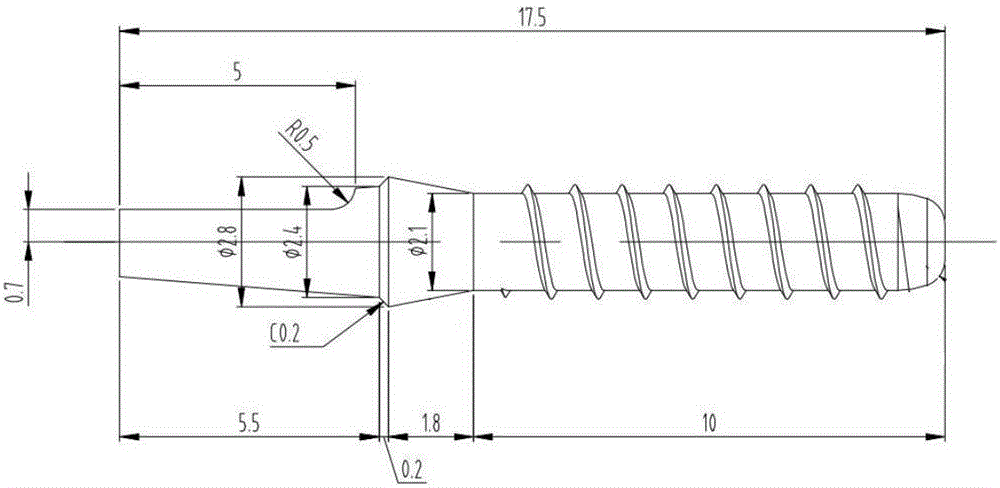

[0035] Step A) Establish a parametric model of the thread height and thread distance of the micro-implant with a diameter of 2.5 mm and a length of 10 mm in the inner bone segment, and use ANSYS Workbench 15.0 software to perform bivariate optimization of the thread height and thread distance. The objective function is implant The contact area between body and bone tissue and the maximum equivalent stress of bone tissue. Select the optimal parameters of ANSYS WorkbenchDesignXplorer, the thread height is 0.3mm, and the thread distance is 0.67mm. After thread optimization, the osseointegration area of the implant increases by 18%, the maximum equivalent stress of cortical bone decreases by 13.8%, and the maximum equivalent stress of cancellous bone decreases by 7.8% %.

[0036] Step B) Use the equal channel extrusion method to prepare ultra-fine-grained pure titanium, the inner angle of the extrusion mold is 120°, and the outer angle is 20°; at room temperature, carry out 4 pa...

Embodiment 2

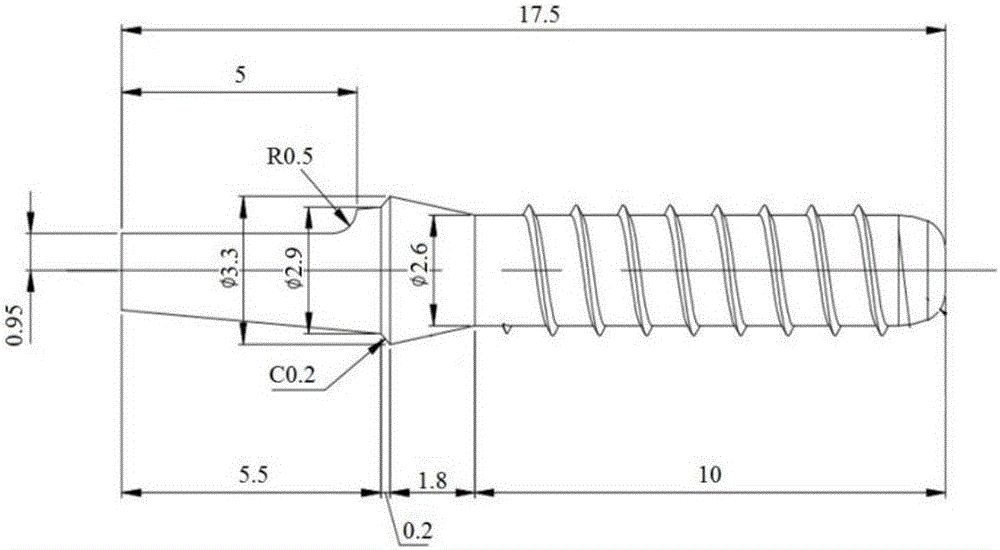

[0041] Step A) Establish a parametric model of the thread height and thread distance of the micro-implant with a diameter of 3.0 mm and a length of the inner bone segment of 10 mm. Use ANSYS Workbench 15.0 software to perform bivariate optimization of the thread height and thread distance. The objective function is implant The contact area between body and bone tissue and the maximum equivalent stress of bone tissue. Select the optimal parameters of ANSYS WorkbenchDesignXplorer, the thread height is 0.35mm, and the thread distance is 0.72mm. After thread optimization, the osseointegration area of the implant increases by 23%, the maximum equivalent stress of cortical bone decreases by 15.4%, and the maximum equivalent stress of cancellous bone decreases by 7.1% %.

[0042] Step B) Use the equal channel extrusion method to prepare ultra-fine-grained pure titanium, the inner angle of the extrusion mold is 120°, and the outer angle is 20°; at room temperature, carry out 4 passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thread height | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com