Automatic-control book lifting mechanism

A notebook and jacking technology, which is applied to machines for issuing pre-printed tickets, coin-operated equipment for distributing discrete items, ticketing equipment, etc. The organization occupies a small space, improves the efficiency and accuracy of distribution, and the effect of precise upward lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

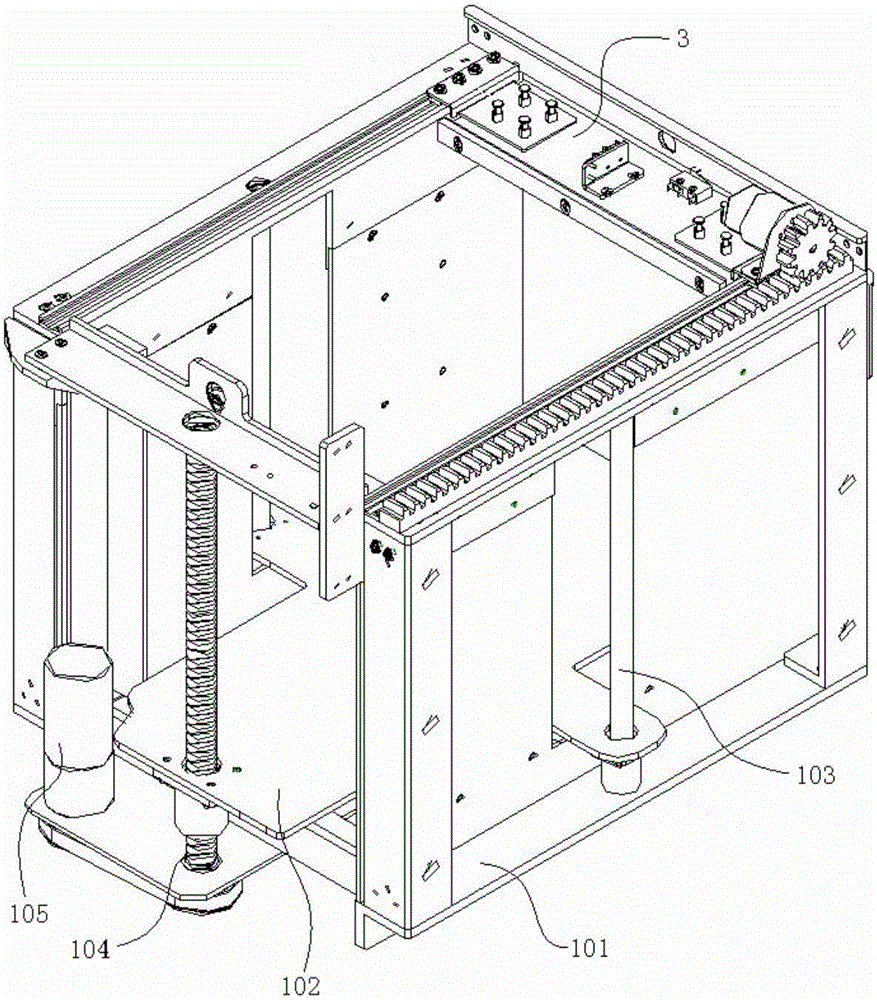

[0029] see figure 1 , the book lifting mechanism in the illustration is one of the preferred implementations of the present invention, specifically including a support frame 101 , a pallet 102 , a guide post 103 , a screw drive assembly 104 and a lifting motor 105 .

[0030] The supporting frame 101 in this embodiment is fixedly arranged, and comprises a bottom plate parallel to the supporting plate 102 and supporting columns around it. The screw drive assembly 104 is arranged above the support frame 101, and the support column of the support frame 101 adopts a right-angle cross section, which can form a position for the book library placed on the supporting plate, and prevent the book from shifting during jacking or distribution.

[0031] Specifically, the screw shaft of the screw drive assembly 104 is installed on the support frame 101 in rotation, the bottom of the screw shaft is connected with the lifting motor 105 through a reduction mechanism, and the nut screwed on the ...

Embodiment 2

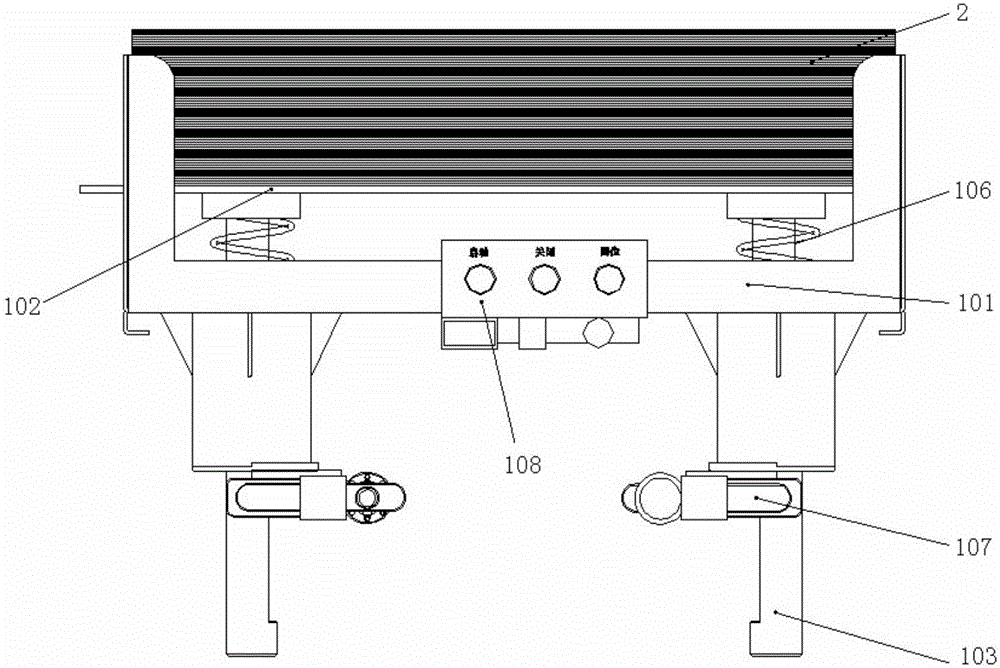

[0039] see image 3 , the book lifting mechanism in the illustration is another preferred embodiment of the present invention, specifically including a support frame 101, a pallet 102, a guide post 103, a lifting spring 106, a locking part 107 and other components.

[0040] The positional relationship between the support frame 101 and the pallet 102 in this embodiment is similar to that of Embodiment 1, the difference is that the jacking assembly in this embodiment uses two sets of guide columns 103 and two sets of compressed lifting springs 106 to form a jacking components. Specifically, the supporting plate 102 and the guide post 103 in this embodiment are fixedly connected by welding or threading, the supporting plate and the guide post go up and down together, the guide post 103 directly passes through the opening provided on the support frame, and the lifting spring 106 is compressed and sleeved on the On the guide post 103, the two ends of the spring are respectively in...

Embodiment 3

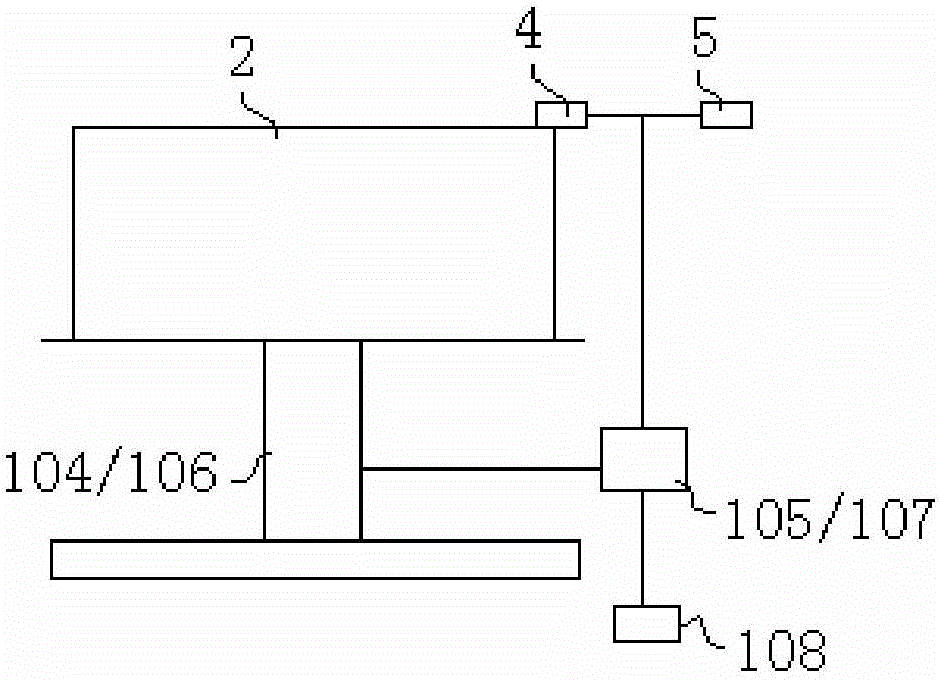

[0049] In this embodiment, on the basis of Embodiment 1 and Embodiment 2, the installation method and working process of the present invention are described in conjunction with the self-adaptive book distribution device.

[0050] see Figure 4 and Figure 5 , the self-adaptive book distribution device in the illustration includes a lifting mechanism 1, a book sub-store 2 and a distribution mechanism 3; wherein the lifting mechanism 1 can adopt the technical solution in embodiment 1 or embodiment 2, and the distribution mechanism 3 balances the platform and the cutter head mechanism Two parts, including motor 301, gear 302, rack 303, limit plate 304, guide seat 305, balance plate 306, micro switch 307, slide rail 308, outlet limit plate 309, cutter head 310 and other components.

[0051] like Figure 4 As shown, the balance platform of the distribution agency is set on the book sub-library 2, and the top book is pushed. The balance platform of the dispensing mechanism takes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com