Variable ground pressure tunnel excavating load experiment platform

A technology for test benches and tunnels, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve problems such as roadheader stalling, changes, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

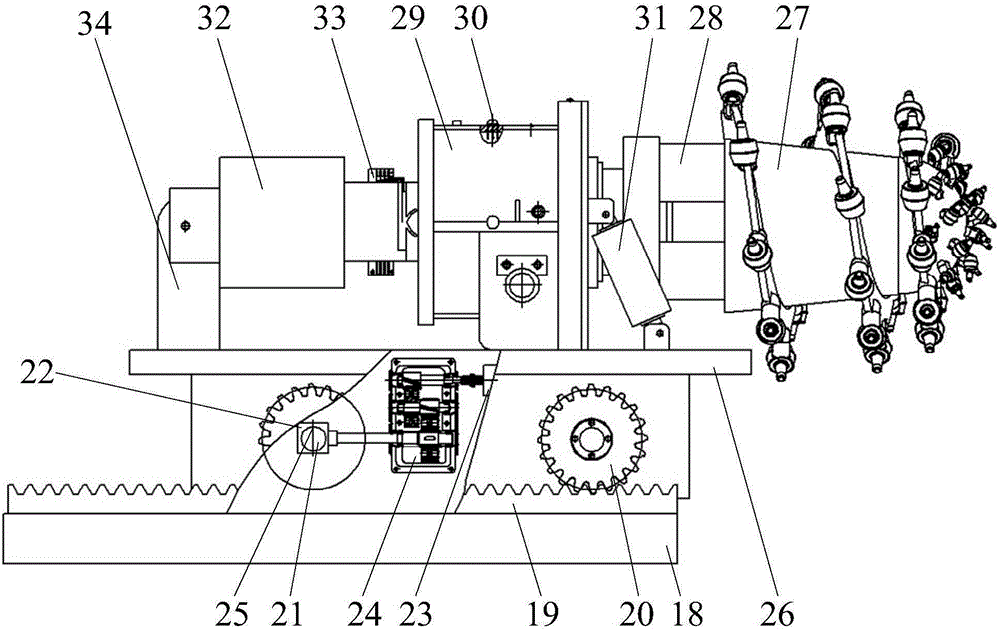

Embodiment 1

[0038] Based on the common complex geological conditions in coal mining roadway excavation construction, that is, the ratio of soft soil to hard rock is 3:7, the initial stress pressure to be loaded is selected, and different ground stresses are realized according to the set stress change curve through the control system. Loading over time. Utilize the first hydraulic cylinder 6 to carry out pressure loading on the simulated rock wall assembly 3; Feedback test data through the first three-way force sensor 9 and the second three-way force sensor 14 to simulate the roadway surrounding rock stress conditions in the excavation process; through the temperature sensor 30 record the change of the working temperature of the reducer 29 under the predetermined construction environment, and draw the temperature change curve; monitor the torque and the change of the rotational speed of the second motor 32 through the torque sensor 33, detect, record and count the test data, Analyze the fo...

Embodiment 2

[0040] In this implementation case, the ratio of soft soil to hard rock under geological conditions is kept at 3:7, and the first hydraulic cylinder 6 is divided into upper and lower groups during the process of pressure loading, which are named group A and group B. , each applying a different pressure value and splitting it into two different cases: pitch and roll.

[0041] Pitching situation: before the drive of the excavation and cutting propulsion mechanism, the pressure loading value of the first hydraulic cylinder 6 of group A is adjusted to make its pressure loading value smaller than that of the first hydraulic cylinder 6 of group B, so that the simulated rock wall assembly 3 and There is a certain elevation angle between the bottom plates 1, on this basis, adjust the rotational speed of the second motor 32, record the pressure value changes of the first three-axis force sensor 9 and the second three-axis force sensor 14, and draw the pressure change curve.

[0042] In...

Embodiment 3

[0044] In this implementation case, the content of hard rock in the geological conditions changes from 70% to 95%. By changing the pressure loading value of the first hydraulic cylinder 6 on the simulated rock wall component 3, the tunneling required by the tunneling machine during the tunneling process is reduced. Cutting force, in order to simulate the sudden change of geological conditions.

[0045] The tunneling load test bench of the variable ground pressure roadway of the present invention can simulate the tunneling process of the shield tunneling machine under the condition that the ground stress does not change, the geological conditions do not change, and the speed of the roadheader does not change. The ground stress does not change, the geological conditions do not change, and the roadheader changes. The tunneling process under the condition of rotating speed, etc.; in the simulation process, the control system is used to record and extract the data of each sensor, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com