Construction process and method for erosion-resistant protective layer of concrete foundation in salty soil zone

A technology for concrete foundation and construction technology, which is applied in basic structure engineering, protection devices, buildings, etc., can solve problems such as high engineering cost, difficult construction, and complicated process, achieve simple process, prevent backflow problems, and ensure stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

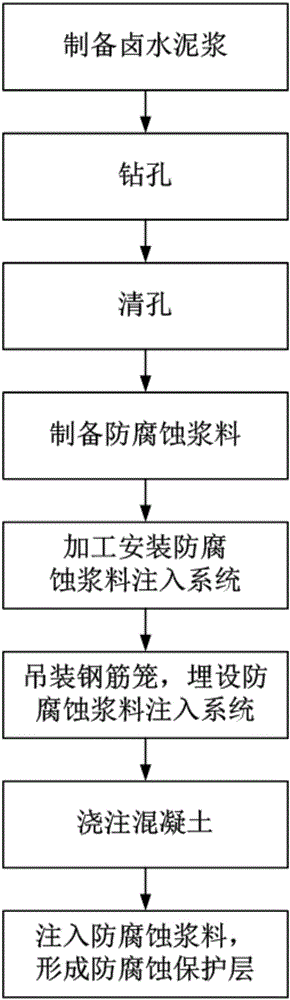

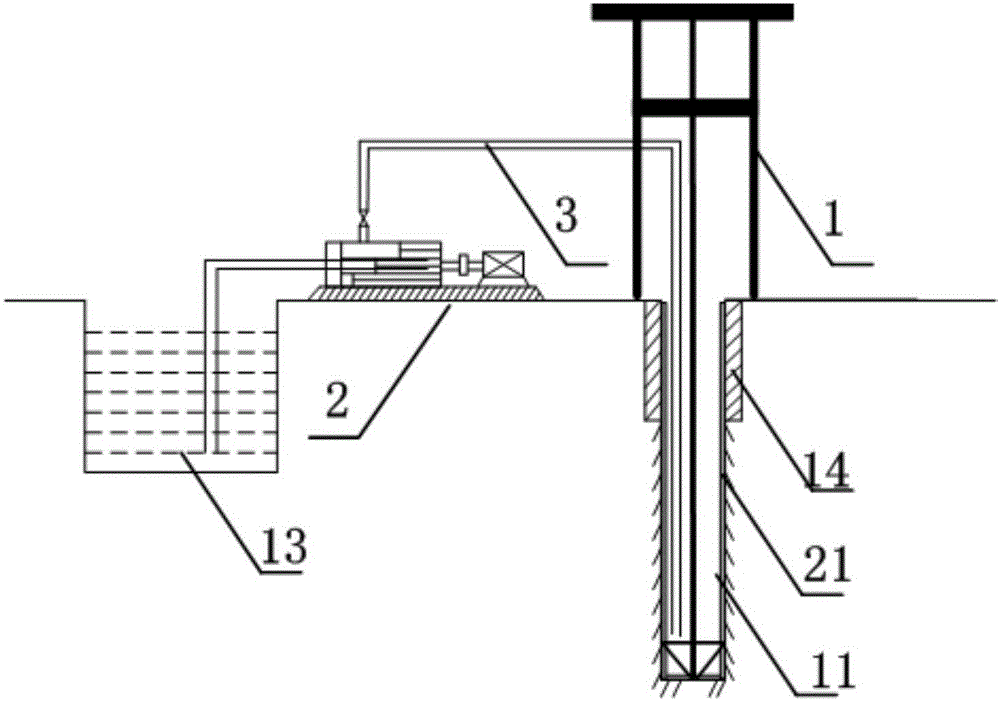

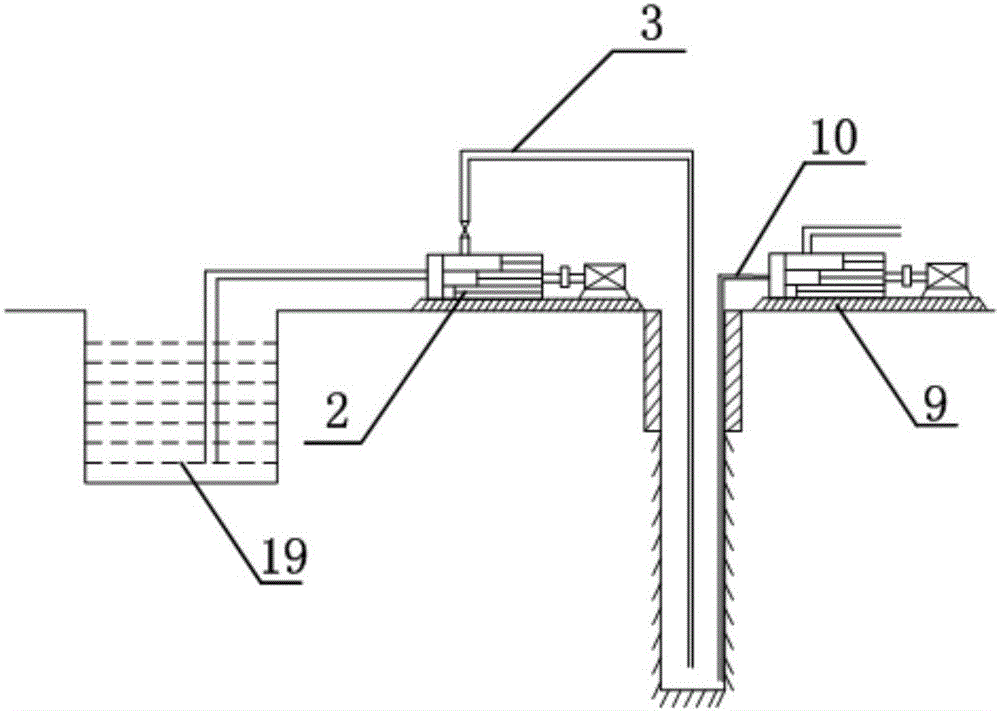

[0095] see Figure 1 to Figure 7 Shown, be specifically that the saline soil area concrete foundation anti-erosion protective layer construction method and technology proposed by the present invention are applied in the saline soil area pouring pile concrete foundation anti-erosion protective layer construction, specifically:

[0096] First, prepare wall retaining mud according to the groundwater environment in the construction area:

[0097] In order to ensure the stability and durability of the retaining mud in the brine environment and reduce the preparation cost of the retaining mud, the brine in the construction area is specially selected to prepare the mixing water for the retaining mud; the retaining mud in the brine environment should at least include bentonite, Adhesive CMC (sodium carboxymethyl cellulose) and other basic components of wall protection mud, and additives can also be selected specifically, such as dispersant FCI (iron chromium lignosulfonate), PHP (poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com