Preparation method of aromatic tobacco extract and application thereof in cigarettes

A technology for oriental cigarettes and extracts, which is applied in the preparation of tobacco, application, essential oils/spices, etc., can solve the problems of heavy components being brought into the condensate surface, difficult to be completely removed, affecting the distillation effect, etc., so as to shorten the production time, Avoid losses and reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

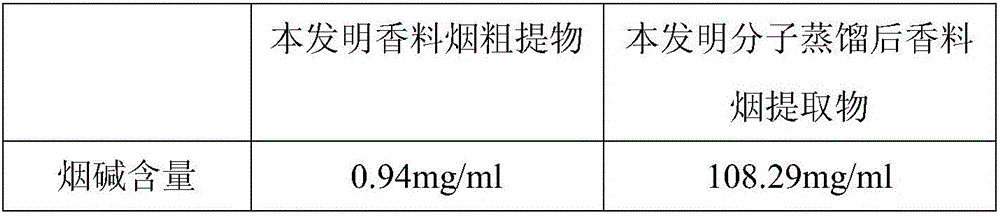

[0022] Embodiment 1, a kind of preparation method of oriental tobacco extract is characterized in that concrete steps are as follows:

[0023] (1) Add 1 kg of oriental tobacco raw material into the extraction tank, add 10 kg of raw material propylene glycol as a solvent, and heat to 60° C. for extraction for 2 hours;

[0024] (2) After the extraction is completed, the solid oriental tobacco raw material is filtered to obtain a liquid crude extract;

[0025] (3) Put the crude extract into the material tank of the molecular distillation equipment; set the molecular distillation process parameters, the scraper speed is 300r / min, the distillation pressure is 300Pa, the distillation temperature is 50°C, and the feed rate is 2ml / min; proceed with the set parameters Molecular distillation treatment is used to obtain light components and heavy components, and the heavy components are oriental tobacco extracts from which part of the propylene glycol solvent has been removed.

[0026] ...

Embodiment 2

[0027] Embodiment 2, a kind of preparation method of oriental tobacco extract, is characterized in that concrete steps are as follows:

[0028] (1) Add 1 kg of oriental tobacco raw material into an extraction tank, add 15 kg of glycerol as a solvent, and heat to 120° C. for 1 hour of extraction;

[0029] (2) After the extraction is completed, the solid oriental tobacco raw material is filtered to obtain a liquid crude extract;

[0030] (3) Put the crude extract into the material tank of the molecular distillation equipment; set the molecular distillation process parameters, the scraper speed is 250r / min, the distillation pressure is 300Pa, the distillation temperature is 55°C, and the feed rate is 2ml / min; proceed with the set parameters The light component and the heavy component were obtained by molecular distillation, and the heavy component was oriental tobacco extract 1# from which part of the glycerin solvent was removed.

[0031] (4) Carry out further molecular distill...

Embodiment 3

[0033] Embodiment 3, a kind of preparation method of oriental tobacco extract, is characterized in that concrete steps are as follows:

[0034] (1) Add 1 kg of oriental tobacco raw material into an extraction tank, add 20 kg of triacetin as a solvent, and heat to 100° C. for 3 hours;

[0035] (2) After the extraction is completed, the solid oriental tobacco raw material is filtered to obtain a liquid crude extract;

[0036] (3) Put the crude extract into the material tank of the molecular distillation equipment; set the molecular distillation process parameters, the scraper speed is 300r / min, the distillation pressure is 300Pa, the distillation temperature is 50°C, and the feed rate is 2ml / min. Molecular distillation treatment to obtain the light component and the heavy component, the heavy component is oriental tobacco extract 1# from which part of the triacetin solvent has been removed;

[0037] (4) Carry out further molecular distillation and separation of the oriental tob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com