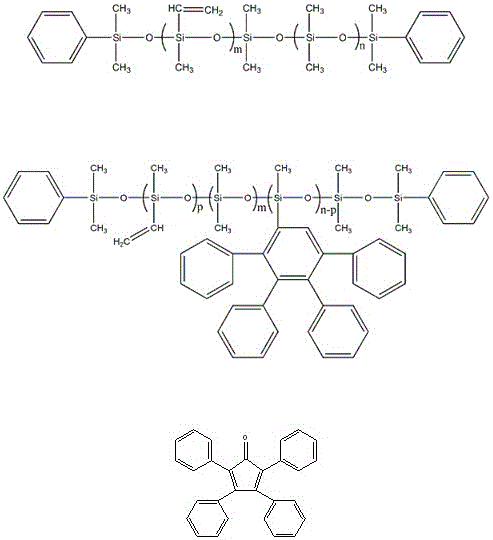

Novel silicone rubber containing phenyl-terminated methylvinyl(tetraphenyl)phenyl

A technology of terminal methyl vinyl group and silicone rubber, applied in the field of silicone rubber, can solve the problem that the performance of ordinary high temperature resistant silicone cannot meet the requirements, and achieve the effect of expanding the scope of use, improving heat resistance and strong steric hindrance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Install a stirrer, condenser tube, and thermometer on a 500ml three-neck round bottom flask. And connect the vacuum filter. Place the three-neck flask in the oil bath. In the three-necked flask, add 230g octamethylcyclotetrasiloxane and 60g tetramethyltetravinylcyclotetrasiloxane, heat up to 90 degrees, N 2 Under protection, vacuumize to -0.08MPa with magnetic stirring, and dehydrate for one hour. Add 8g of tetraphenyldivinyldisiloxane and 6g of tetramethylammonium hydroxide, raise the temperature to 110°C, and react for three hours. Then raise the temperature of the system to 160° C., react for 1 hour to decompose the catalyst, and evaporate the low boilers under reduced pressure to obtain the liquid product, phenyl-terminated methyl vinyl silicone oil. Mix, stir well and set aside.

[0031] (2) Add polyphenyl-terminated methylvinyl silicone oil, tetraphenylcyclopentadienone, and a mass ratio of 5.03:1 into a 70ml reaction kettle, at a temperature of 200°C unde...

Embodiment 2

[0034] (1) Install a stirrer, condenser tube, and thermometer on a 500ml three-neck round bottom flask. And connect the vacuum filter. Place the three-neck flask in the oil bath. In the three-necked flask, add 230g octamethylcyclotetrasiloxane and 60g tetramethyltetravinylcyclotetrasiloxane, heat up to 90 degrees, N 2 Under protection, vacuumize to -0.08MPa with magnetic stirring, and dehydrate for one hour. Add 8g of tetraphenyldivinyldisiloxane and 6g of tetramethylammonium hydroxide, raise the temperature to 110°C, and react for three hours. Then raise the temperature of the system to 160° C., react for 1 hour to decompose the catalyst, and evaporate the low boilers under reduced pressure to obtain the liquid product, phenyl-terminated methyl vinyl silicone oil. Mix, stir well and set aside.

[0035] (2) Add polyphenyl-terminated methylvinyl silicone oil, tetraphenylcyclopentadienone, and a mass ratio of 5.03:1 into a 70ml reaction kettle, at a temperature of 200°C unde...

Embodiment 3

[0038] (1) Install a stirrer, condenser tube, and thermometer on a 500ml three-neck round bottom flask. And connect the vacuum filter. Place the three-neck flask in the oil bath. In the three-necked flask, add 230g octamethylcyclotetrasiloxane and 60g tetramethyltetravinylcyclotetrasiloxane, heat up to 90 degrees, N 2 Under protection, vacuumize to -0.08MPa with magnetic stirring, and dehydrate for one hour. Add 8g of tetraphenyldivinyldisiloxane and 6g of tetramethylammonium hydroxide, raise the temperature to 110°C, and react for three hours. Then raise the temperature of the system to 160° C., react for 1 hour to decompose the catalyst, and evaporate the low boilers under reduced pressure to obtain the liquid product, phenyl-terminated methyl vinyl silicone oil. Mix, stir well and set aside.

[0039] (2) Add polyphenyl-terminated methylvinyl silicone oil, tetraphenylcyclopentadienone, and a mass ratio of 5.03:1 into a 70ml reaction kettle, at a temperature of 200°C unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com