A kind of concentrated hydrochloric acid hydrolysis process and device

A concentrated acid hydrolysis and hydrolysis device technology, applied in the fields of organic chemistry, silicon organic compounds, chemical instruments and methods, etc., can solve problems such as affecting the normal operation of the equipment, unfavorable oil-water separation, and decreasing the yield of the ring body, and improve the reaction efficiency. and product quality, improve separation, reduce coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

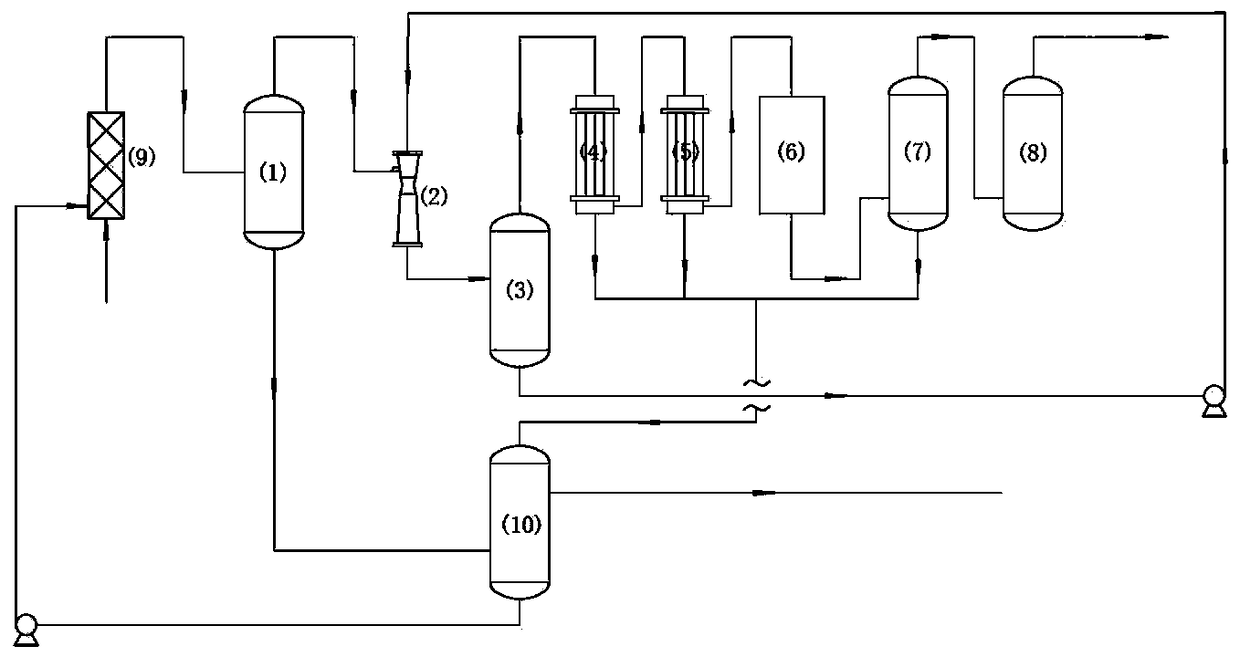

[0018] Control the hydrolysis reaction between dimethyldichlorosilane and concentrated hydrochloric acid in a static mixer at 35°C and 0.2MPa, and the resulting gas-liquid mixture enters the gas-liquid separation tank A (1) for separation, and the gas-liquid separation tank A (1 ) The gas produced at the top enters the Venturi mixer (2) and is fully mixed with the concentrated hydrochloric acid main fluid. The mass concentration of the concentrated hydrochloric acid is 38%, and the mass ratio of the concentrated acid to the gas mixture is 1:3. The gas-liquid separation tank B (3) is separated, the liquid extracted from the bottom of the gas-liquid separation tank B (3) is returned to the Venturi mixer through the material pump, and the gas extracted from the top is passed through the primary condenser (4) and the secondary condenser (5) The final temperature is -10°C and the pressure is 0.15MPa. The liquid extracted from the bottom of the gas-liquid separation tank (1) and the...

Embodiment 2

[0020] Control the hydrolysis reaction between dimethyldichlorosilane and concentrated hydrochloric acid in a static mixer at 35°C and 0.2MPa, and the resulting gas-liquid mixture enters the gas-liquid separation tank A (1) for separation, and the gas-liquid separation tank A (1 ) The gas produced at the top enters the Venturi mixer (2) and is fully mixed with the concentrated hydrochloric acid main fluid. The mass concentration of the concentrated hydrochloric acid is 38%, and the mass ratio of the concentrated acid to the gas mixture is 1:4. The gas-liquid separation tank B (3) is separated, the liquid extracted from the bottom of the gas-liquid separation tank B (3) is returned to the Venturi mixer through the material pump, and the gas extracted from the top is passed through the primary condenser (4) and the secondary condenser (5) The final temperature is 0°C and the pressure is 0.20MPa. The liquid extracted from the bottom of the gas-liquid separation tank (1) and the c...

Embodiment 3

[0022] Control the hydrolysis reaction between dimethyldichlorosilane and concentrated hydrochloric acid in a static mixer at 35°C and 0.2MPa, and the resulting gas-liquid mixture enters the gas-liquid separation tank A (1) for separation, and the gas-liquid separation tank A (1 ) The gas produced at the top enters the Venturi mixer (2) and is fully mixed with the concentrated hydrochloric acid main fluid. The mass concentration of the concentrated hydrochloric acid is 38%, and the mass ratio of the concentrated acid to the gas mixture is 1:5. The gas-liquid separation tank B (3) is separated, the liquid extracted from the bottom of the gas-liquid separation tank B (3) is returned to the Venturi mixer through the material pump, and the gas extracted from the top is passed through the primary condenser (4) and the secondary condenser (5) The final temperature is 10°C and the pressure is 0.25MPa. The liquid extracted from the bottom of the gas-liquid separation tank (1) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com