A waste edge online coiling device for aluminum processing equipment

A technology of coiling device and aluminum processing, applied in metal processing equipment, shearing device, accessory device of shearing machine, etc., can solve the problems of uniformity, inability to guarantee constant tension of waste strips, waste of coiling space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

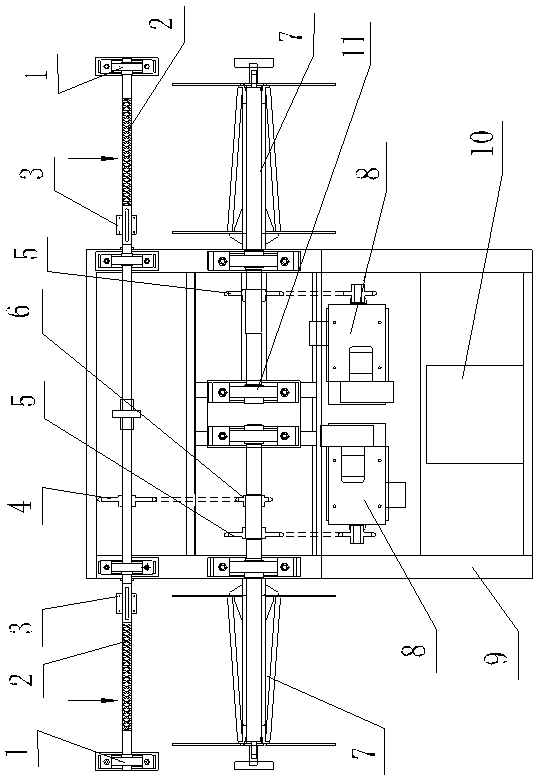

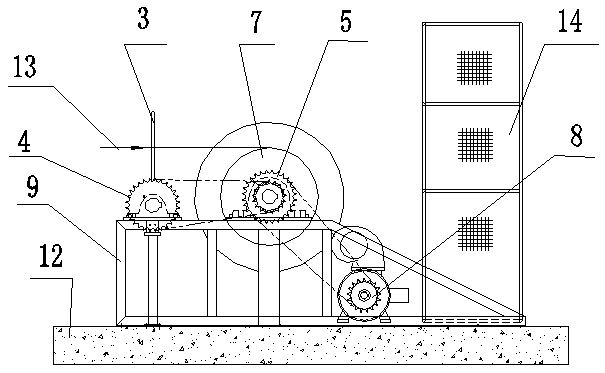

[0018] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, this embodiment includes a frame 9, a control cabinet 10, and two sets of coiling devices (it can also be one set. When one set is used, the coiling efficiency is low, and it can only be used in conjunction with a waste edge shearing machine that works on one side) . Two groups of coiling devices are installed on the frame 9 oppositely. Each set of winding devices includes a torque motor 8, a winding shaft 7 and a guide device 2. The frame 9, the torque motor 8 and the control cabinet 10 are fixed on the foundation 12. The mandrel of take-up shaft 7 is hinged on the frame 9 through two bearing blocks 11 . The guiding device 2 includes a bidirectional recirculating lead screw 16 , a frame guide frame 3 , a slide blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com