Method for online automatic maintaining of hot-rolled laminar cooling manifolds

A laminar cooling and cooling header technology, applied in workpiece cooling devices, metal rolling, metal rolling, etc., can solve the problems of quality impact, short life, and high failure rate of laminar cooling headers, and reduce the failure rate. , the effect of ensuring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

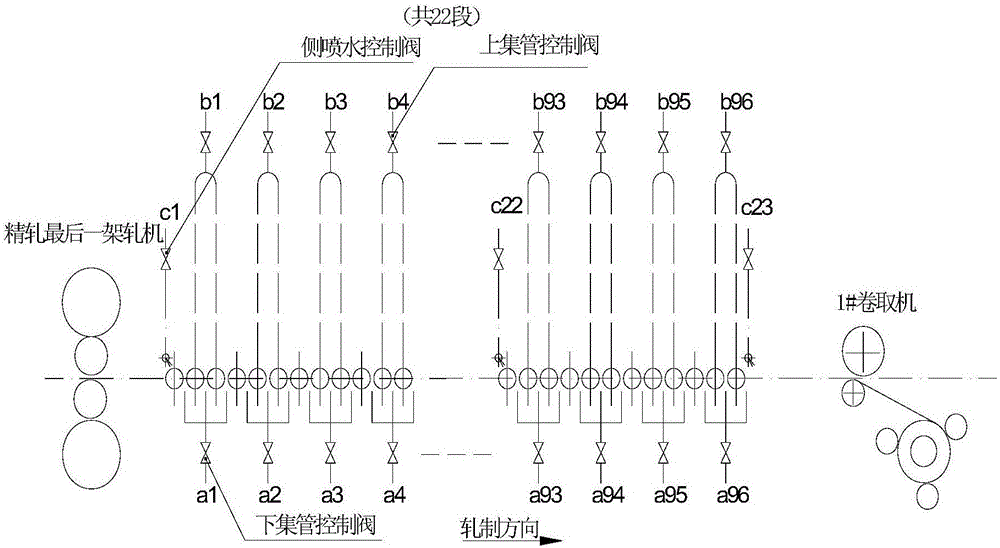

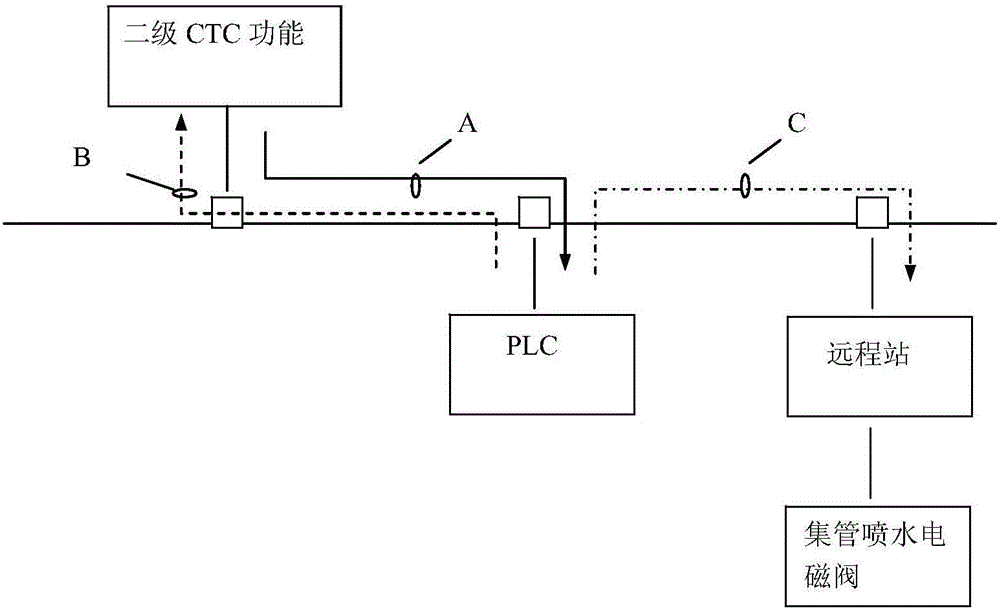

Method used

Image

Examples

Embodiment Construction

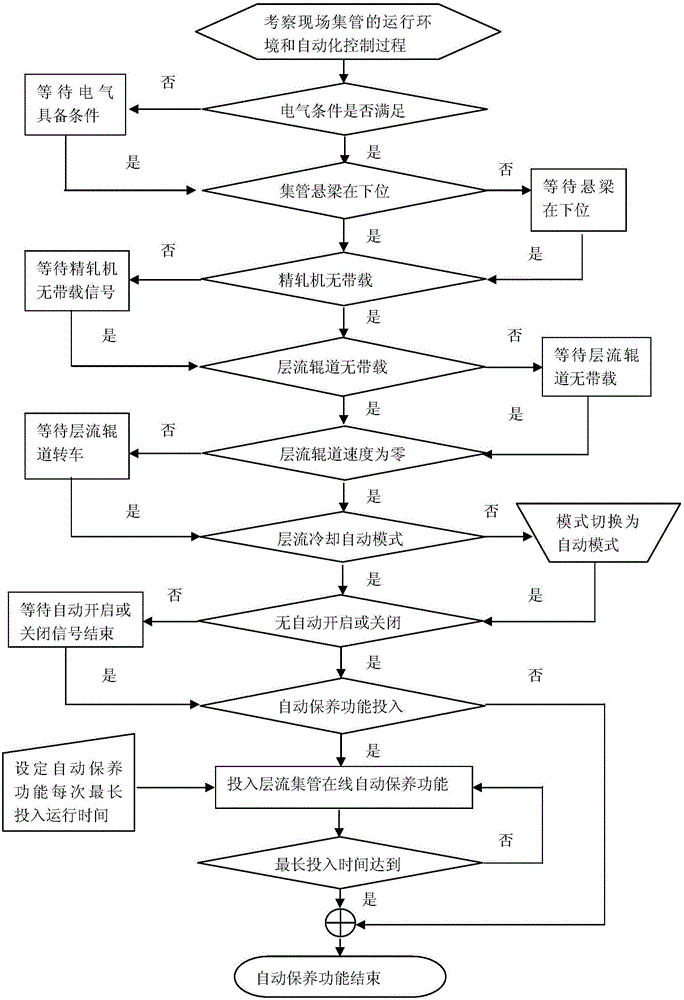

[0026] image 3 It is the specific implementation method of online automatic maintenance of hot-rolled laminar flow cooling headers. First, make preparations and fully understand the current equipment composition, automatic control system and process of laminar cooling header water spraying, and expand ideas for the development of maintenance functions. , master the key points of control; on the premise of ensuring that the laminar flow cooling header can meet the process control requirements during steel rolling, add the maintenance function of the laminar flow cooling header to ensure the stable operation of all equipment in the laminar flow area.

[0027] Step 1. Determine whether the power supply of the solenoid valve controlling the water spray of the laminar flow cooling header is normal, and whether the cantilever of each group of laminar flow cooling header is in the lower position. When the power supply of the solenoid valve is normal and the cantilever is in the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com