An outdoor dielectrophoresis dust removal equipment

A technology of dielectrophoresis and dust removal equipment, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of uneven electric field, failure to achieve the purpose of the invention, etc., and achieve the effect of easy regulation and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

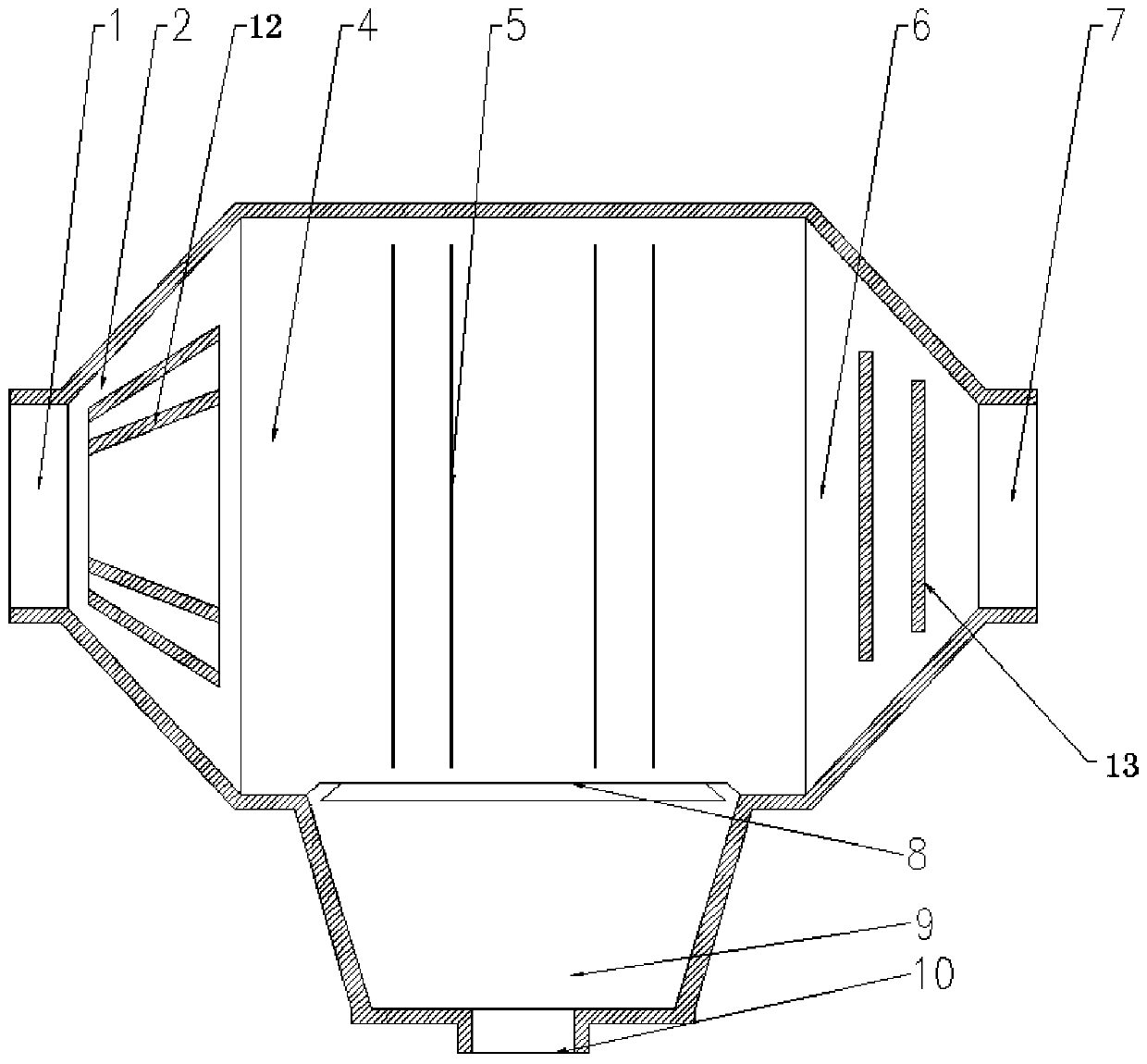

[0058] Such as figure 1 As shown, a kind of outdoor dielectrophoresis dust removal equipment of this embodiment mainly includes a box body 11, an air inlet 1, a mixed flow control room 2, a dielectrophoresis dust removal room 4, a parallel electrode group 5, an outlet smoke box 6, and an air outlet 7 and dust chamber 9. Among them, the box body 11 is a nearly spindle-shaped structure with two ends narrowed and the middle part bulged. One end is provided with an air inlet 1, and the other end is provided with an air outlet 7. It is the dielectrophoresis dust removal chamber 4, and the narrowed part near the air outlet is the outlet smoke box 6. Corresponding to the opening on the bulging part below the dielectrophoretic dust removal chamber 4, a dust collection chamber 9 is connected to the outside of the opening for collecting the dust and particles captured by the parallel electrode groups through the dielectrophoretic force. In this dust collection chamber The bottom of 9 ...

Embodiment 2

[0061] Such as figure 2 As shown, a kind of outdoor dielectrophoretic dedusting equipment of this embodiment differs from that of embodiment 1 in that the mixed flow control chamber 2 is equipped with an air inlet coaxial with the air inlet 1 and gradually expands to the dielectrophoretic dedusting chamber 4. Conical deflector 12. The conical baffles 12 can also be a set of conical baffles coaxially spaced apart. The function of the conical deflector 12 is to evenly distribute the airflow at the air inlet 1, so that the airflow enters the DEP dust removal chamber 4 according to the required speed and direction, so as to avoid the influence of the excessive airflow velocity or direction deviation on the DEP force dust removal effect. In addition, a group of ash collecting baffles 13 arranged in parallel are fixed in the outlet smoke box 6. In this embodiment, they are arranged perpendicular to the direction of the air flow, and the side facing the direction of the air flow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com