Spherical alumina carrier and preparation method thereof

A spherical alumina, carrier technology, applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of raw material powder pore volume and specific surface area damage, unfavorable human health, low strength and brittleness, etc. To achieve the effect of easy control of particle size, short time-consuming and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

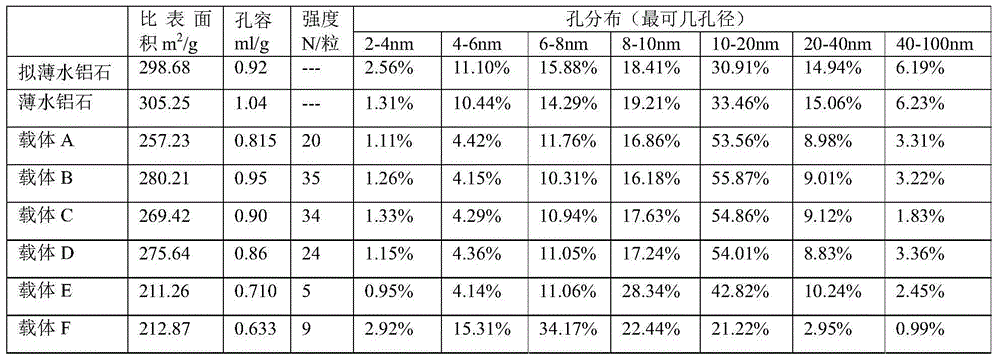

[0040] This example is used to illustrate the spherical alumina carrier prepared by the method of the present invention

[0041] Raw material preparation: weighing pore volume is 0.85cm 3 11kg of the first raw material powder pseudo-boehmite / g, the polymer compound binder is dissolved in 14L of water at a temperature of 40°C to form an aqueous solution of the binder; wherein, the addition of the binder is 0.01% by weight of the first raw material powder pseudo-boehmite on a dry basis, and the total volume of the aqueous solution of the binder is 1 time of the first raw material powder pseudo-boehmite on a dry basis;

[0042] Then, the first raw material powder pseudo-boehmite and the aqueous solution of the binder are mixed and granulated in a mixing granulator, wherein the mixing and granulating process includes the first mixing process and the second mixing process carried out in sequence, First, in the first mixing process, the rotating speed of the mixing tool is 1500 rpm...

Embodiment 2

[0046] This example is used to illustrate the spherical alumina carrier prepared by the method of the present invention

[0047] Raw material preparation: weighing pore volume is 0.95cm 3 30kg of the first raw material powder pseudo-boehmite / g, the polymer compound binder is dissolved in 18L water at a temperature of 40°C to form an aqueous solution of the binder; wherein, the addition of the binder is 2.0% by weight of the dry weight of the first raw material powder pseudo-boehmite, and the total volume of the aqueous solution of the binder is 3 times the dry weight of the first raw material powder pseudo-boehmite;

[0048] Then, the aqueous solution of the first raw material powder pseudo-boehmite and the binder is mixed and granulated in a mixing granulator, wherein the mixing and granulating process includes the first mixing process and the second mixing process carried out in sequence, first In the first mixing process, the rotating speed of the mixing tool is 2000 rpm, ...

Embodiment 3

[0052] This example is used to illustrate the spherical alumina carrier prepared by the method of the present invention

[0053] Raw material preparation: weighing pore volume is 0.92cm 3 11kg of the first raw material powder pseudo-boehmite / g, the polymer compound binder is dissolved in 16L of water at a temperature of 40°C to form an aqueous solution of the binder; wherein, the addition of the binder is 0.5% by weight of the dry weight of the first raw material powder pseudo-boehmite, and the total volume of the aqueous solution of the binder is twice the dry weight of the first raw material powder pseudo-boehmite;

[0054] Then, the aqueous solution of the first raw material powder pseudo-boehmite and the binder is mixed and granulated in a mixing granulator, wherein the mixing and granulating process includes the first mixing process and the second mixing process carried out in sequence, first In the first mixing process, the rotating speed of the mixing tool is 1800 rpm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com