High heat dissipation drive circuit module based on stage light high power led

A technology of LED drive board and drive circuit, which is applied in the use of semiconductor lamps, cooling/heating devices of lighting devices, electric light sources, etc. Large and other problems, to achieve the effect of compact structure, cost saving, easy installation, maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

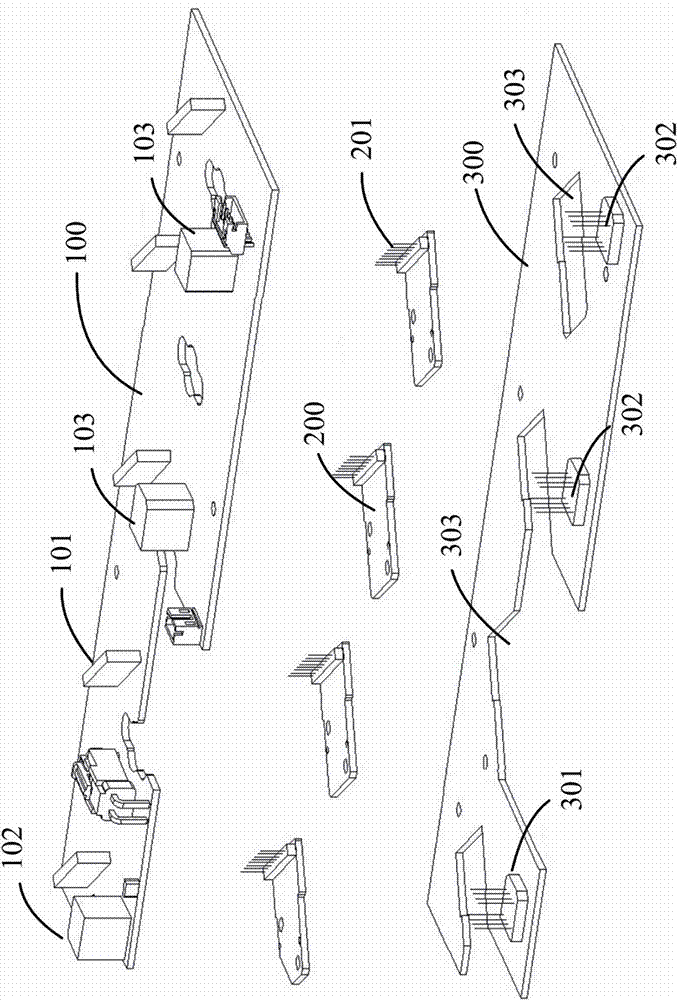

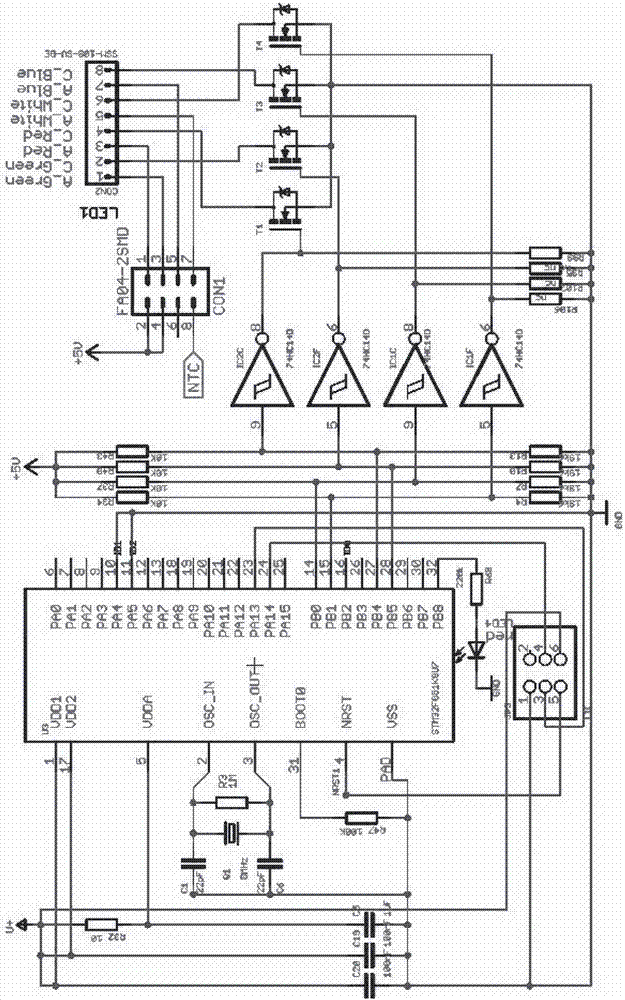

[0032] Such as Figure 1-4As shown, the first embodiment of the present invention provides a high heat dissipation driving circuit module based on high-power LED of stage lights, including LED driving board 100, LED board 200 and LED power board 300;

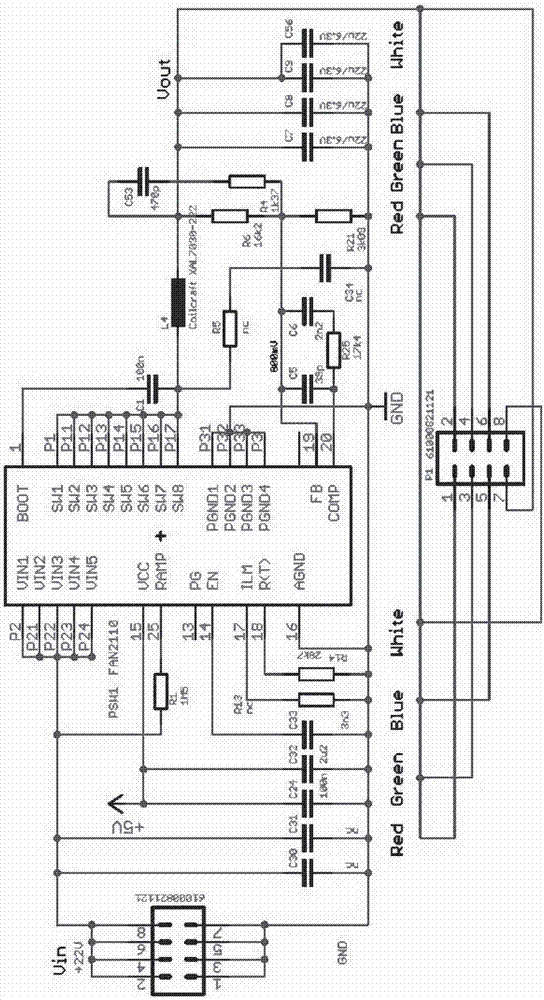

[0033] The LED power board 300 provides power for the LED driver board 100 and the LED board 200; the LED driver board 100 is used to drive the LED lights on the LED board 200 to work;

[0034] The LED driver board 100 is provided with a single-row female seat 101 and a double-row female seat. The single-row female seat 101 on the LED power supply board 300 is electrically connected to the double-row male seat, and is electrically connected to the double-row female seat on the LED driver package board through the double-row male seat;

[0035] The double-row male seat includes a first double-row male seat 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com