A multi-phase permanent magnet synchronous motor drive system and its control method

A permanent magnet synchronous motor, drive system technology, applied in motor generator control, electronic commutation motor control, single motor speed/torque control, etc., can solve the threat of no motor-converter-controller integrated design, The overall operating performance of major equipment and the inability to achieve system optimization and combination, to achieve the effects of simple and feasible methods, low torque ripple, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The patent of the present invention will be further described below in conjunction with the drawings.

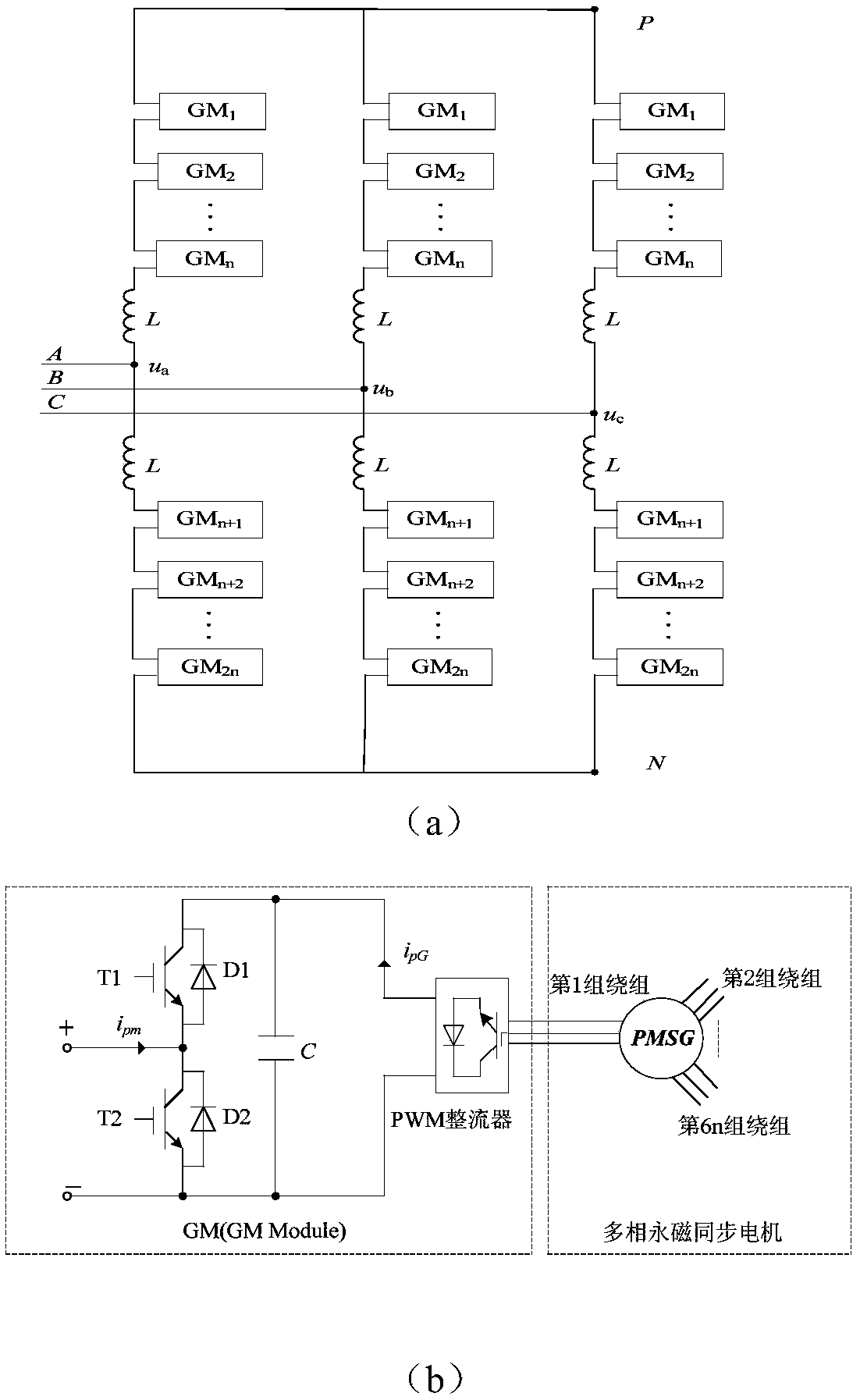

[0038] figure 1 It is the topological structure and sub-module structure diagram of the multi-phase permanent magnet synchronous motor drive system. The drive system includes a modular multi-level inverter; the number of phases of the multi-phase permanent magnet synchronous motor is 18n (n=1,2, 3...); The modular multi-level inverter adopts a three-phase six-arm structure, each phase includes two upper and lower bridge arms, and each bridge arm is connected in series by n GM sub-modules and a filter inductor L The upper and lower bridge arms lead to the phase line; the three phase lines are connected to the public grid; the GM sub-module includes a PWM rectifier, two IGBT tubes T1 to T2, two diodes D1 to D2, and a capacitor C; Among them, the emitter of the IGBT tube T1 is connected to the collector of the IGBT tube T2 to form the positive terminal of GM, the collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com