Gas cooling device and gas cooling method of power battery pack

A power battery pack and gas cooling technology, which is applied in the fields of high-power power battery pack gas cooling for vehicles, high-power power battery pack gas cooling devices for vehicles, and power battery pack gas cooling devices, can solve the problem of consuming power battery power and water cooling. The problems of large system volume and large cooling system volume can achieve the effect of simple structure, good cooling effect and increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as Figure 4-10 As shown, the power battery pack gas cooling device includes:

[0046] - Disc cooling medium channel 2, such as Figure 2-5 As shown in , 10, the disc-type cooling medium channel is used for gas coolant flow, and the disc-type cooling medium channel is located in the middle of the two rows of power battery cells 4; the cooling medium is preferably air or nitrogen;

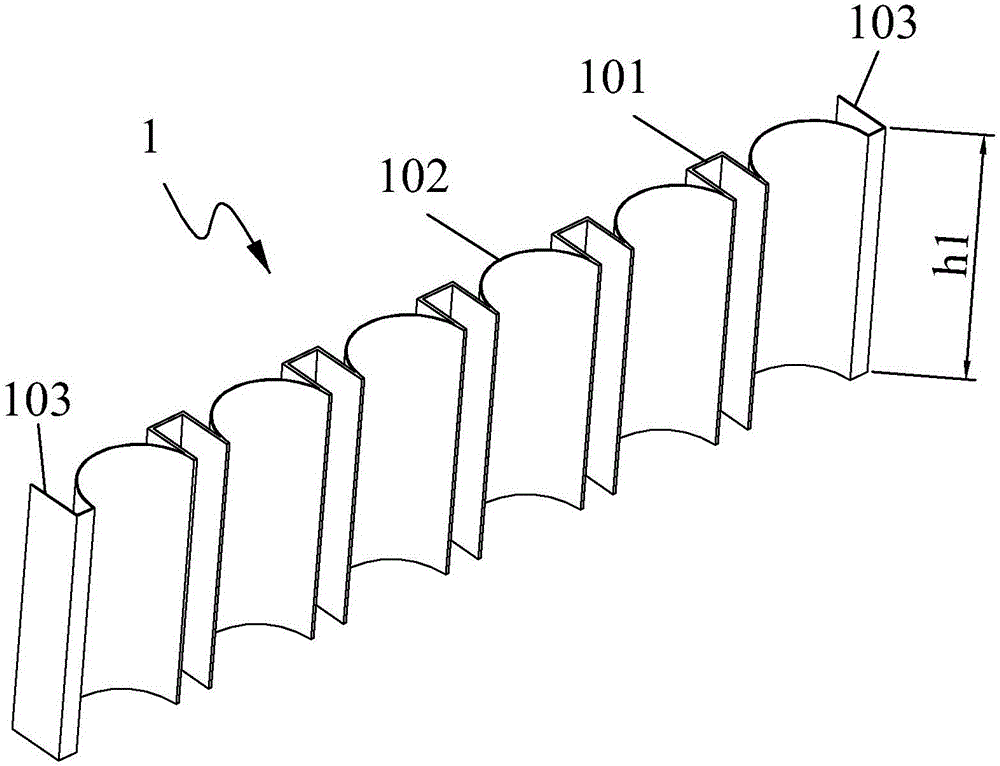

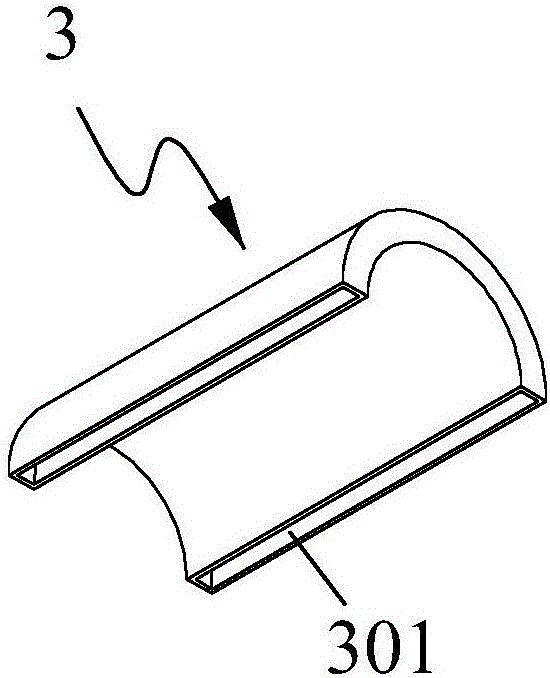

[0047] --Such as figure 1 , 4As shown in -10, at least one pair of heat sinks 1, any one of the heat sinks includes at least one arc portion 102; the inner side of the combined pair of heat sink arc portions matches the shape of the battery core of the power battery pack, and the combined The outer sides of the arc portion of the last pair of fins are tangent to the wall of the disk-type cooling medium channel; and the combined pair of fin ends 103 are in contact with the disk-type cooling medium channel.

[0048] For example, if Figure 4 As shown, a battery pack has 8 columns x 6 ...

Embodiment 2

[0055] like figure 1 , 4 , 5, and 10, as an improvement of the power battery pack gas cooling device of the present invention, any one of the cooling fins includes at least two arc-shaped parts 102, and a raised part is arranged in the middle of the two arc-shaped parts 101, such as Figure 9 As shown in , the raised portion is in contact with the disk cooling medium channel. The protruding part 101 can function as a thermal bridge, speed up heat transfer, and improve heat dissipation and cooling effects.

[0056] like Figure 4 As shown, a battery pack has 8 columns x 6 rows of battery cells. like figure 1 , 5 , 10, a heat sink 1 has six arcs 102, five protrusions 101 and two ends 103. like Figure 4 As shown, a pair of heat sinks can wrap a row of battery cells.

[0057] The heat of the heat sink can be transferred to the plate-type cooling medium channel through more reliable contact parts, further improving the cooling effect.

Embodiment 3

[0059] like Figure 1-10 As shown, the power battery pack gas cooling method, wherein:

[0060] There is a disc-type cooling medium channel 2 between the cells of the two rows of power battery packs, and the disc-type cooling medium channel is used for gas coolant flow; the cooling medium is preferably air or nitrogen;

[0061] The outside of any battery core in the power battery pack is covered with an arc-shaped heat sink 1, and the heat of the battery core passes through the arc portion 102 of the heat sink and the end portion 103 of the heat sink and the heat in the disk cooling medium passage. The gas realizes heat exchange.

[0062] When working, the gas cooling medium, such as air, nitrogen, passes through the plate cooling medium channel. The heat sink transfers heat to the plate-type cooling medium channel through the arc and both ends, and the flowing gas coolant takes out the heat conducted by the heat sink to the plate-type cooling medium channel to achieve effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com