Lithium battery anode slurry mixing solvent and method for preparing lithium battery anode slurry by using solvent

A lithium battery and mixed solvent technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of environmental and human hazards, high prices, etc., and achieve the effects of low raw material prices, easy recycling, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this example, the solvent for the positive electrode slurry of the lithium battery is N,N-dimethylacetamide, dimethyl sulfoxide, tetramethylurea, and trimethyl phosphate mixed according to the molar ratio of 6:2:1:1. into a mixed solvent;

[0026] The preparation method of the lithium battery cathode slurry using the mixed solvent comprises the following steps:

[0027] S1. Weigh the following raw materials by weight percentage: 94.5% of lithium iron phosphate, 1.0% of conductive carbon black, 1.5% of carbon nanotubes, and 3.0% of polyvinylidene fluoride;

[0028] S2. Weigh 10Kg of lithium iron phosphate, 0.1058Kg of conductive carbon black, and 0.1587Kg of carbon nanotubes, put them in a vacuum oven at 150°C, bake for 20 hours, weigh 0.3175Kg of polyvinylidene fluoride and put them in a vacuum oven at 80°C medium, bake for 20 hours, set aside;

[0029] S3. Add 4Kg of mixed solvent and 0.3175Kg of polyvinylidene fluoride baked in step S2 to the vacuum mixer, stir a...

Embodiment 2

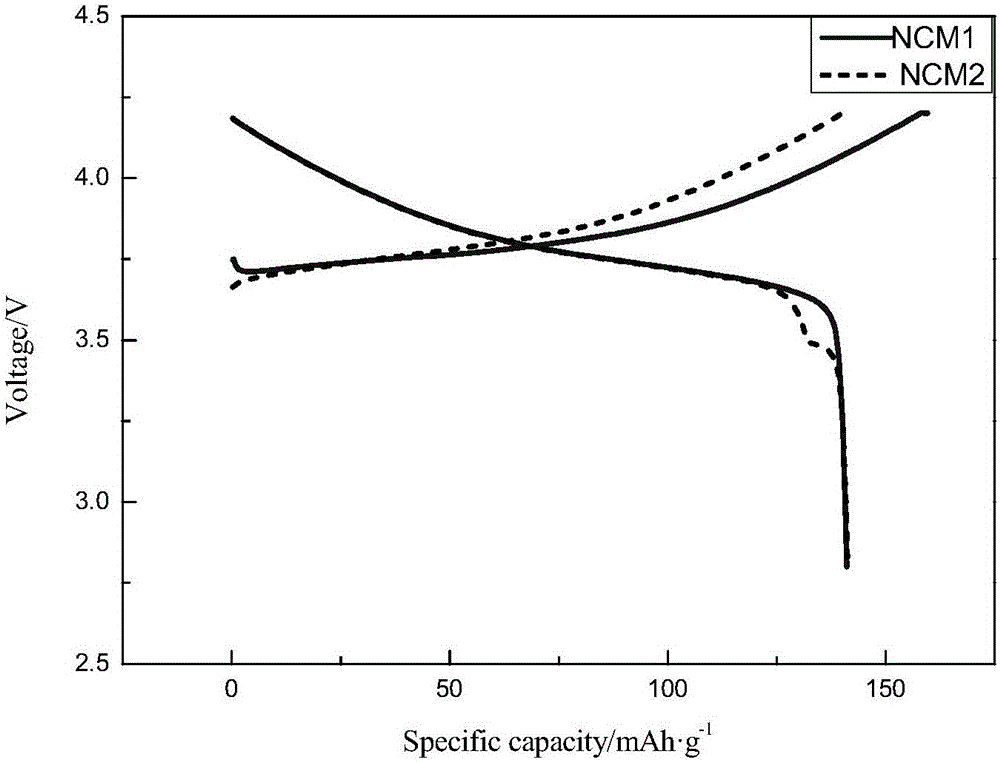

[0043] In this embodiment, nickel-cobalt-lithium-manganese-oxide ternary material is selected as the positive electrode material, wherein the molar ratio of nickel-cobalt-manganese in the nickel-cobalt-lithium-manganese-oxide ternary material is 1:1:1, and the positive electrode slurrying solvent of the lithium battery in this embodiment is N , N-dimethylacetamide, dimethyl sulfoxide, tetramethylurea, and trimethyl phosphate are mixed solvents in a molar ratio of 6:3:0.5:0.5;

[0044] The preparation method of the lithium battery cathode slurry using the mixed solvent comprises the following steps:

[0045] S1. Weigh the following raw materials in weight percentage: 95% of lithium iron phosphate, 2.5% of conductive carbon black, 0.5% of graphite conductive agent, and 3.0% of polyvinylidene fluoride;

[0046] S2. Weigh 10Kg of nickel-cobalt lithium manganate ternary material, 0.2632Kg of conductive carbon black, and 0.0526Kg of graphite conductive agent, put them in a vacuum ov...

Embodiment 3

[0061] In this embodiment, nickel-cobalt-lithium-manganese-oxide ternary material is selected as the positive electrode material, wherein the molar ratio of nickel-cobalt-manganese in the nickel-cobalt-lithium-manganese-oxide ternary material is 1:1:1, and the positive electrode slurrying solvent of the lithium battery in this embodiment is N , N-dimethylacetamide, dimethyl sulfoxide, tetramethylurea, and trimethyl phosphate are mixed solvents in a molar ratio of 7:2:0.5:0.5;

[0062] The preparation method of the lithium battery cathode slurry using the mixed solvent comprises the following steps:

[0063] S1. Weigh the following raw materials in weight percentage: 95% of lithium iron phosphate, 2.5% of conductive carbon black, 0.5% of graphite conductive agent, and 3.0% of polyvinylidene fluoride;

[0064] S2. Weigh 10Kg of nickel-cobalt lithium manganese oxide ternary material, 0.2632Kg of conductive carbon black, and 0.0526Kg of graphite conductive agent, put them in a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com