An intelligent constant temperature system for industrial and mining JP cabinets

A constant temperature system and intelligent technology, applied in the direction of temperature control, electrical components, and substation/switchgear cooling/ventilation using electric means, which can solve the harsh working environment of JP cabinet equipment, damage to electrical appliances in JP cabinets, and corrosion of electrical equipment. and other problems, to achieve the effects of reliable fluidity and thermal conductivity, suppression of electrification, and stable oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

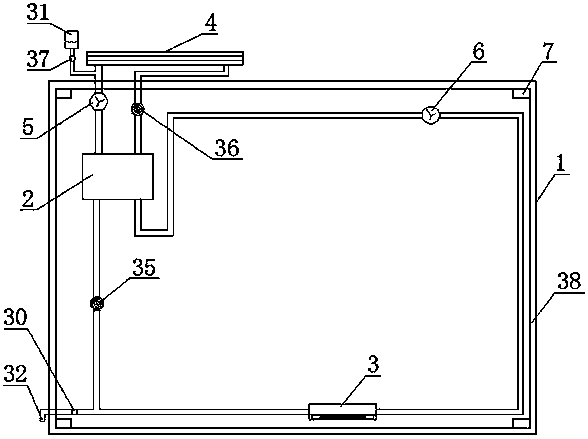

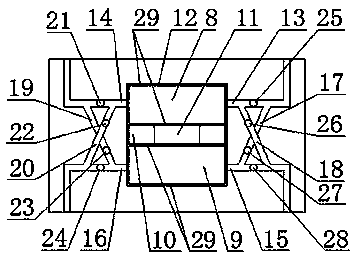

[0043] like figure 1 and figure 2 As shown, an intelligent constant temperature system of a JP cabinet for industrial and mining use includes a JP cabinet body 1, a cooling and heating device 2, an internal heat exchanger 3, an external heat exchanger 4, a first driving oil pump 5, a second driving oil pump 6 and several A temperature sensor 7; the JP cabinet body 1 is provided with a cooling and heating device 2, an internal heat exchanger 3, a first driving oil pump 5, a second driving oil pump 6 and several temperature sensors 7, and the outside of the JP cabinet body 1 is provided There is an external heat exchanger 4; the refrigerating and heating device 2 includes a heater 8, a refrigerator 9, a controller 10, and several groups of semiconductor cooling fins 11 and a housing 12; the upper end of the housing 12 is provided with a The heater 8 is provided with a refrigerator 9 at the lower end of the housing 12, and a controller 10 and several groups of semiconductor ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com