Multi-boiler drum liquid level header system energy-saving water supply system and control method thereof

A technology of drum liquid level and control system, which is used in the control of water supply, steam generation, lighting and heating equipment, etc., can solve problems such as the drop of the drum liquid level, the impact of system safety, and the safety of dry boilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

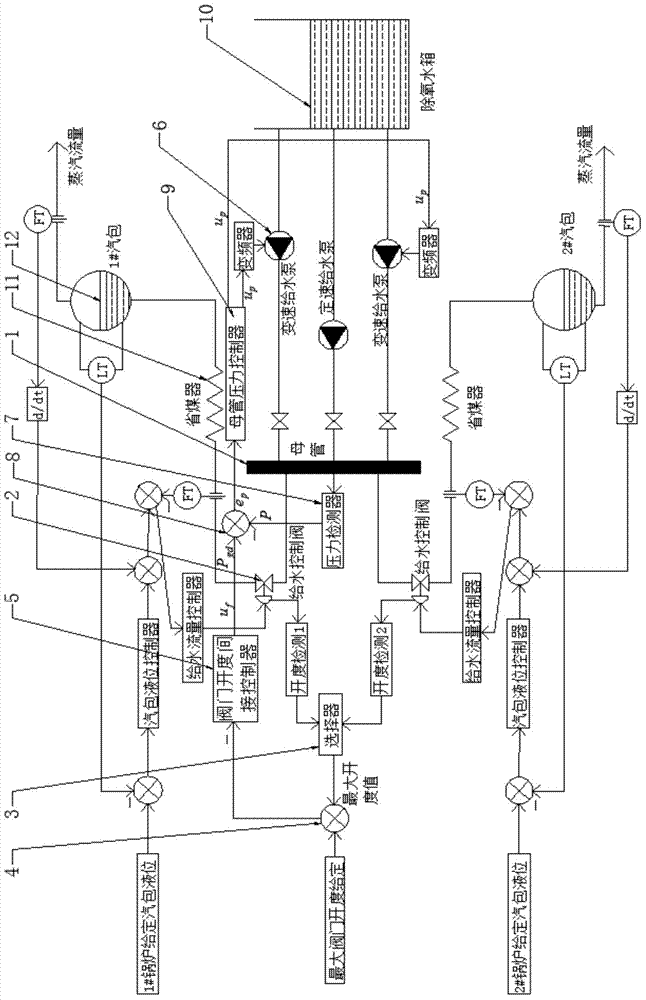

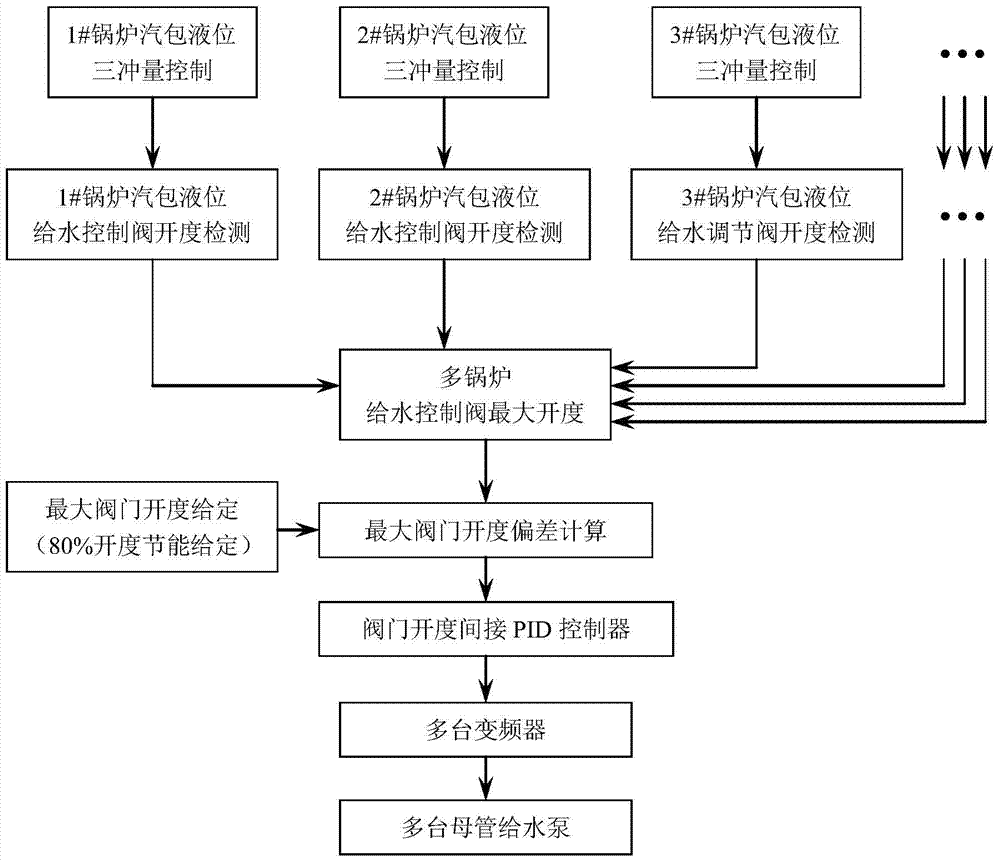

[0049] Such as figure 1 As shown in the figure, an energy-saving water supply control system with multi-boiler drum liquid level main control system includes at least two sets of boiler liquid level systems that supply water through the same main pipe 1. This embodiment takes the boiler liquid level system of two boiler drums as an example To illustrate, each set of boiler liquid level system is composed of deaeration water tank 10, feed water pump 6, feed water control valve 2, economizer 11, steam drum 12 and pipelines connected therein, and each set of boiler liquid level The feed water control valve 2 of the system is controlled by a three-impulse control system based on the drum liquid level, load steam flow and feed water flow, and the opening values of all the feed water control valves 2 are uniformly provided to the valve opening control system;

[0050] Boilers now use three-impulse technology, but the oldest single-impulse boiler control technology, that is, the dr...

Embodiment 2

[0067] See attached figure 1 , an energy-saving water supply control system for multi-boiler drum liquid level master pipes, including at least two sets of boiler liquid level systems that supply water through the same master pipe 1. This embodiment takes two sets of boiler liquid level systems as an example for illustration. The boiler The liquid level system consists of a deoxygenated water tank 10, a feed water pump 6, a feed water control valve 2, an economizer 11, a steam drum 12 and the pipelines connected therein, and the feed water control valve 2 of each set of the boiler liquid level system is based on The three-impulse control system controls the drum liquid level, load steam flow and feedwater flow, and the opening values of all the feedwater control valves 2 are uniformly provided to the valve opening control system;

[0068] The valve opening control system is provided with a selector 3 and an indirect valve opening controller 5, the input end of the selector 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com