Shallow-buried biased segment tunnel stratum reinforcement construction method

A construction method and shallow burial technology, applied in tunnels, tunnel lining, excavation, etc., can solve the problems of complex stress state of surrounding rock and hidden dangers of construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

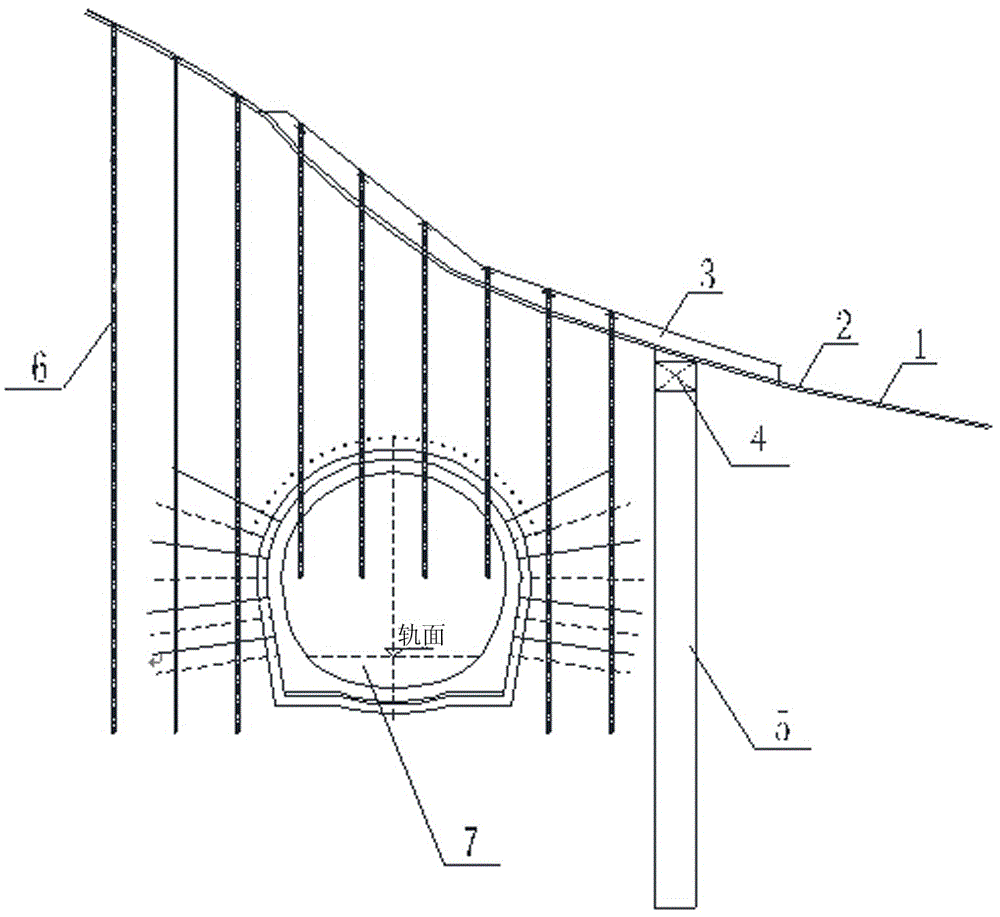

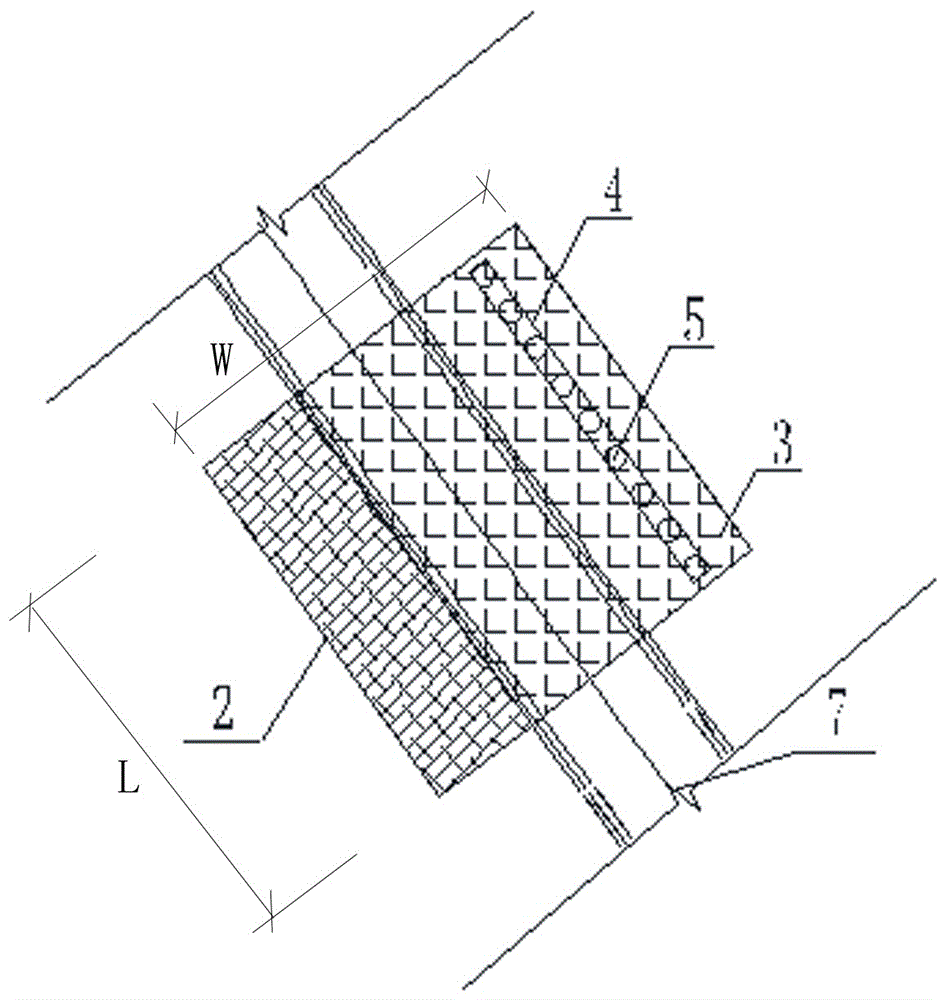

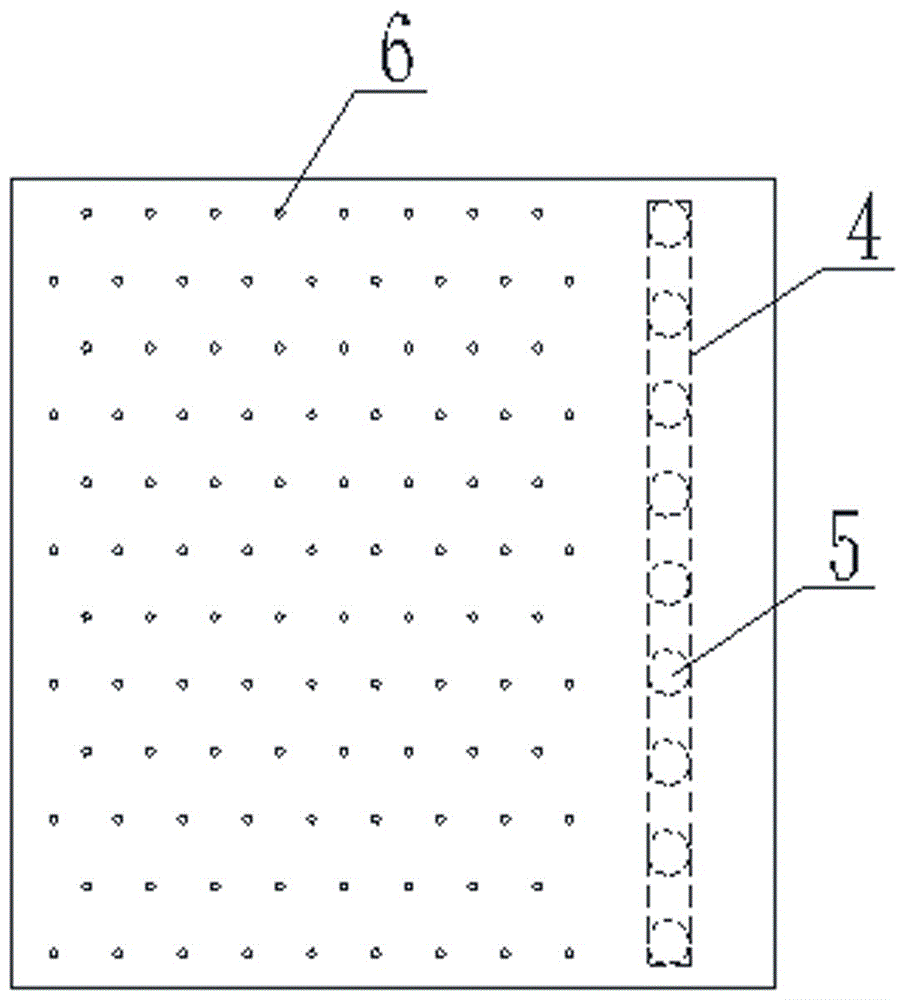

[0028] The present invention prevents bias phenomenon after tunnel excavation by reinforcing the V-shaped gully at the top of the tunnel. The reinforcement device includes sprayed concrete (2), reinforced concrete cover plate (3), crown beam (4), Anti-slide piles (5) and steel flower pipes (6), sprayed concrete (2) are installed on the clear surface layer of the section to be reinforced, anti-slide piles (5) are installed on the bias side of the tunnel along the longitudinal direction of the tunnel, crown beams (4) are installed All the anti-slide piles (5) are connected as a whole on the top of the anti-slide piles (5). It is arranged on the top of the anti-slide pile (5) and the steel flower tube (6), and the steel plate at the top end of the steel flower tube (6), the connecting steel bar of the mesh sprayed concrete (2) layer and the main reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com