Ammonification anthropomorphic inspection type intelligent control system for condensed water in once-through boiler and control method

A technology of intelligent control system and once-through boiler, applied in general control system, control/regulation system, water treatment parameter control, etc., can solve water circulation system and boiler water vapor equipment corrosion, pH value deviates from the control range, and pH value fluctuates greatly To achieve the effect of ensuring precise and stable control, overcoming the hysteresis of pH value change, and precise dosage control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

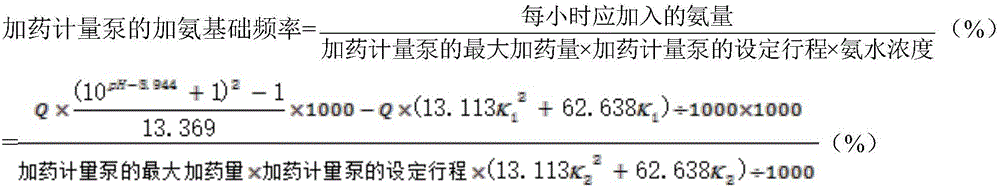

[0040] Such as figure 1 As shown, the anthropomorphic inspection type intelligent control system for condensed water and ammonia of the once-through boiler of the present invention includes:

[0041] The flow meter is set on the pipeline of the condensate pump outlet pipe, and is used to collect the real-time flow Q of the condensate pump;

[0042] The first conductivity meter is set at the centralized sampling rack, and the sampling point is set on the pipeline of the effluent pipe of the finishing system to collect the conductivity value κ of the effluent water of the finishing system before adding ammonia 1 ;

[0043] The second conductivity meter is connected to the ammonia solution tank and is used to collect the conductivity value κ in the ammonia solution tank 2 ;

[0044] The third conductivity meter is set at the centralized sampling rack, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com